Comprehensive tension matching method with goal of quality control in strip steel shearing process

A shearing process and strip technology, applied in the field of metallurgy, can solve the problems of strip slippage and difficult execution, and achieve the effect of ensuring optimality and avoiding slippage of strip trimming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

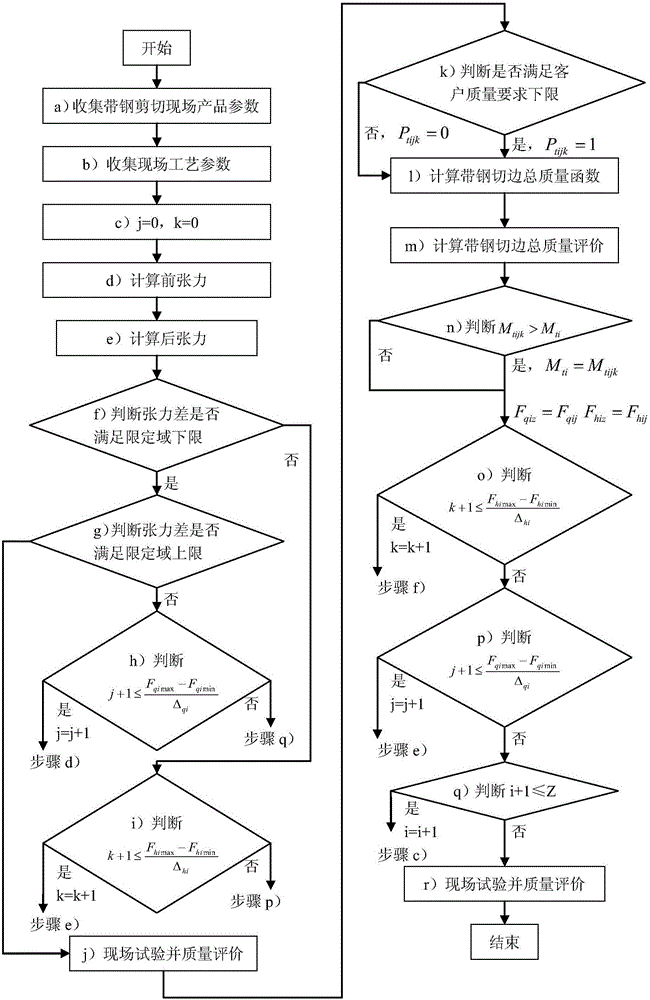

[0028] In order to further illustrate the application process of the technology of the present invention, taking a certain finishing unit process section as an example, the application process and use effect of the method of the present invention on the spot are introduced in detail. The overall flow is as follows figure 1 Shown:

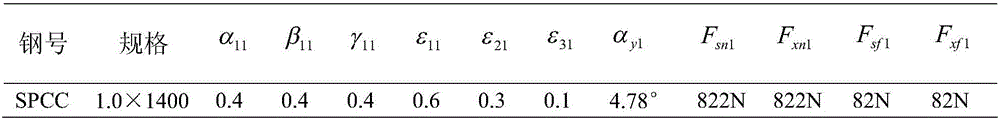

[0029] (1) Collect product parameters, product number i = 1, collect first-close parameters as follows:

[0030] Table 1 Typical strip product parameters of a finishing unit

[0031]

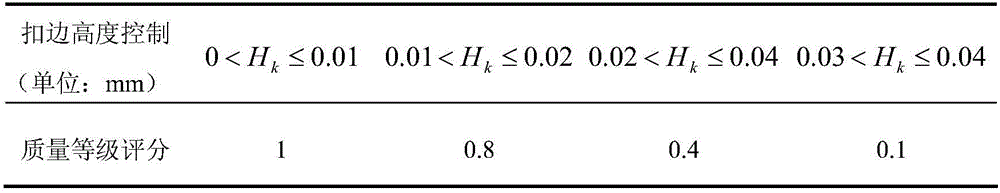

[0032] (2) Collect on-site process parameters. For the first type of strip steel, limit the front tension limit to 21.15N / mm according to the process requirements before and after the on-site trimming equipment 2 , The minimum value of the front tension limit is 21N / mm 2 , The maximum limit of back tension is 21N / mm 2 , The minimum value of back tension limit is 20.8N / mm 2 , the front tension search step is 0.05N / mm 2 , back tension search step size 0.05N / mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com