Unloading type liquid-control hydraulic break valve and its opening method

A globe valve, hydraulic control technology, applied in the device for pressure relief on the sealing surface, lift valve, valve details, etc., can solve the problem of affecting frequency and reliability, large pressure difference between front and rear oil ports, and shearing of the sealing ring. Deformation and other problems, to achieve the effect of improving reliability and service life, ensuring reasonable values, and facilitating automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

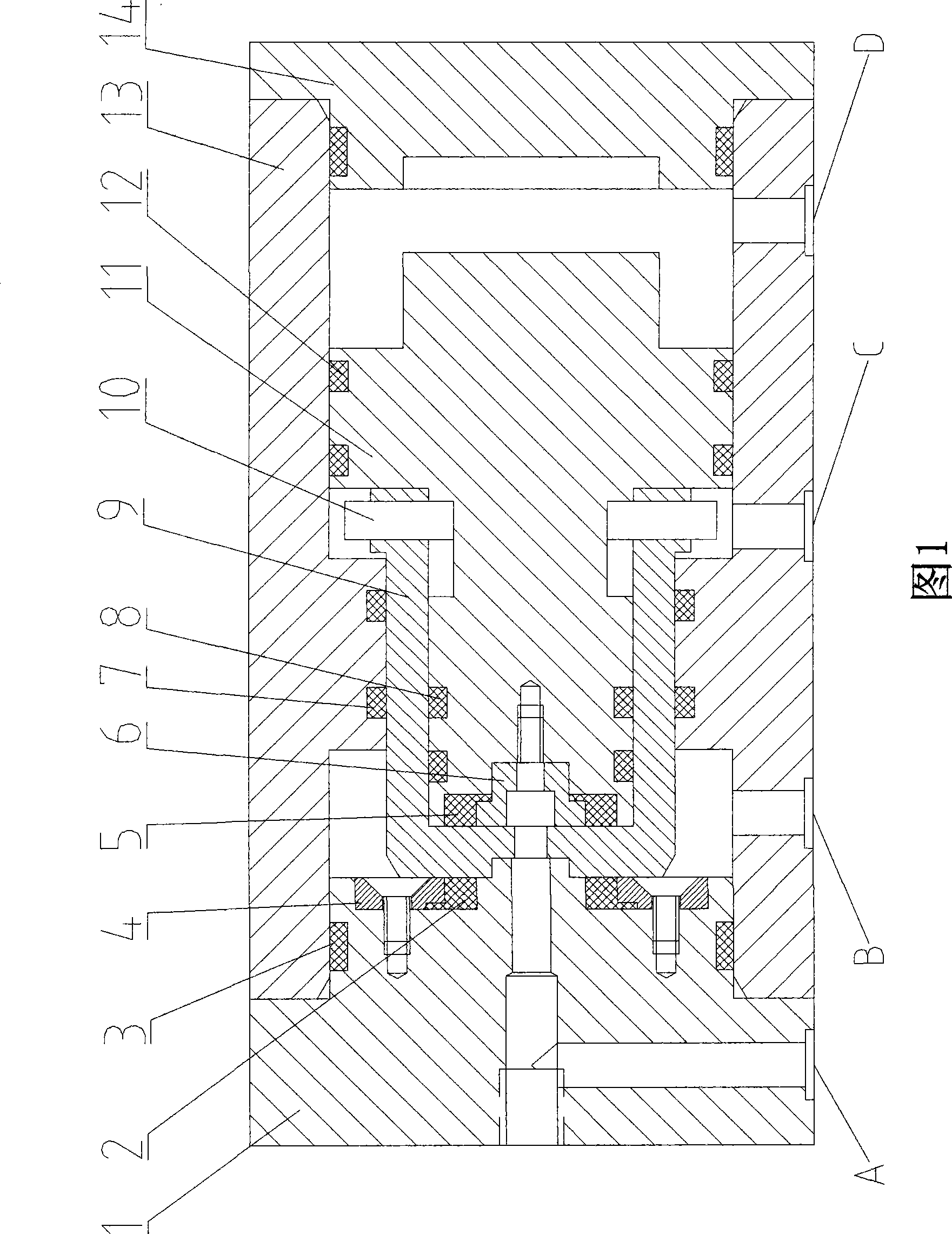

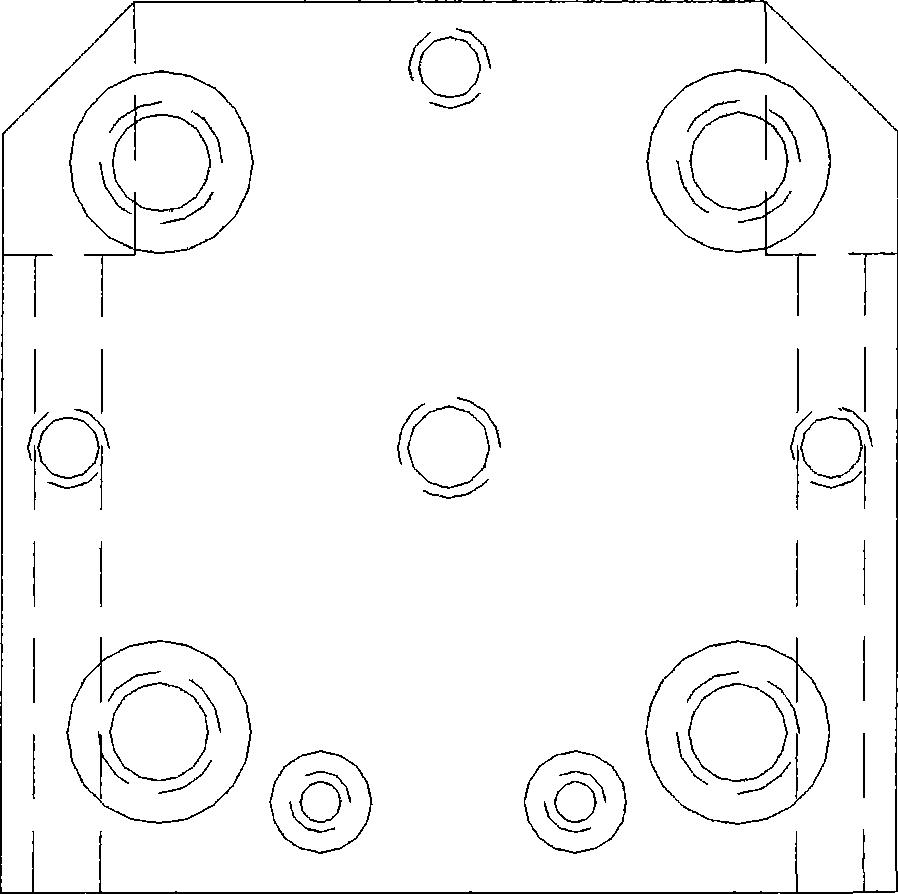

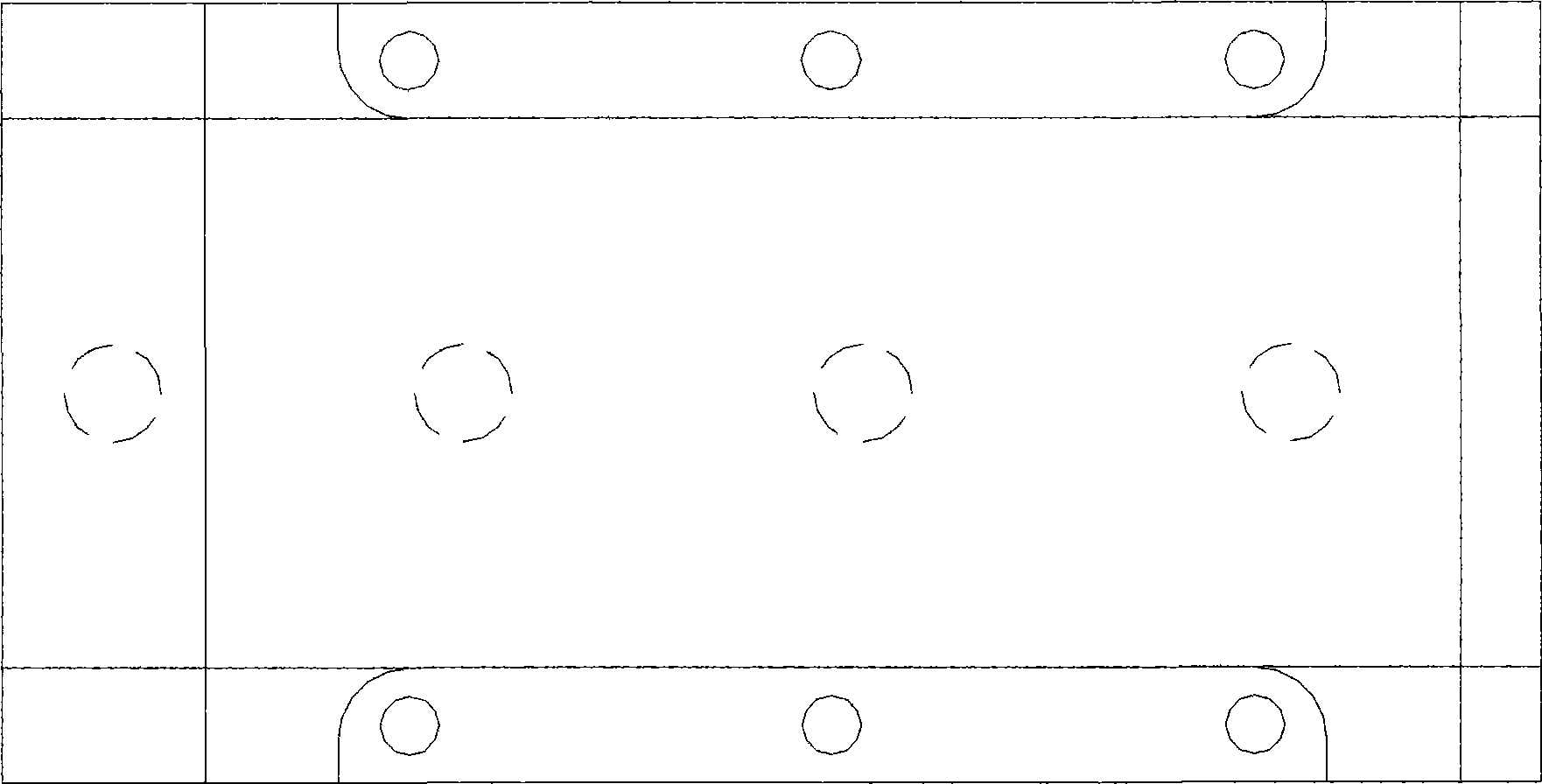

[0032] Control attached Figure 1-5 , the specific implementation process of the present invention is described as follows:

[0033] figure 1 main view, figure 2 for the left view, image 3 is a top view, where 1 is the left end cover, through figure 2 The shown bolts are tightly connected with the valve body 13; 2 is the first end face seal ring, 5 is the second end face seal ring, the first end face seal ring 2 is fixed on the left end cover 1 through the pressure ring 4; the second end face seal ring 5 It is fixed on the plunger 11 through the pressure cap 6; 3 is a static sealing ring; Part of the plug rod fits; 10 is a column pin, one end of which is installed in the pin hole of the sliding sleeve 9, and the other end is inserted in the keyway of the plunger rod part of the plunger 11; 14 is the right end cover, similarly, through the bolt and the valve body 13 Fasten the connection.

[0034] control figure 1 , A and B in the figure are main oil circuit connect...

Embodiment 2

[0037] Embodiment 2 Hydraulic cut-off valve opening method

[0038] One of the characteristics of the present invention is to unload first and then open the main oil circuit. In addition to the above-mentioned method of integrating the unloading functional element and the switch element, it is also possible to install a hydraulic cylinder somewhere in the controlled high-pressure chamber or use other volume intervention methods to unload. Such as Figure 7 , E is the controlled high-pressure chamber; G is the stop valve; H is the plunger cylinder; F is the connecting oil circuit. When opening the main oil passage, first move the plunger of the plunger cylinder to the right to expand the volume of the blocked high-pressure chamber so that the pressure of the hydraulic oil in the chamber will drop to achieve unloading, and then the stop valve piston will Move to the right to open the main oil circuit. At this time, the globe valve can remove the sliding sleeve, and only the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com