Measurement Method of Intracavity Linear Loss of All-Solid-State Laser

A measurement method and laser technology, applied in the laser field, can solve problems such as limitations, and achieve the effects of low cost, easy practical operation, simple experimental equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

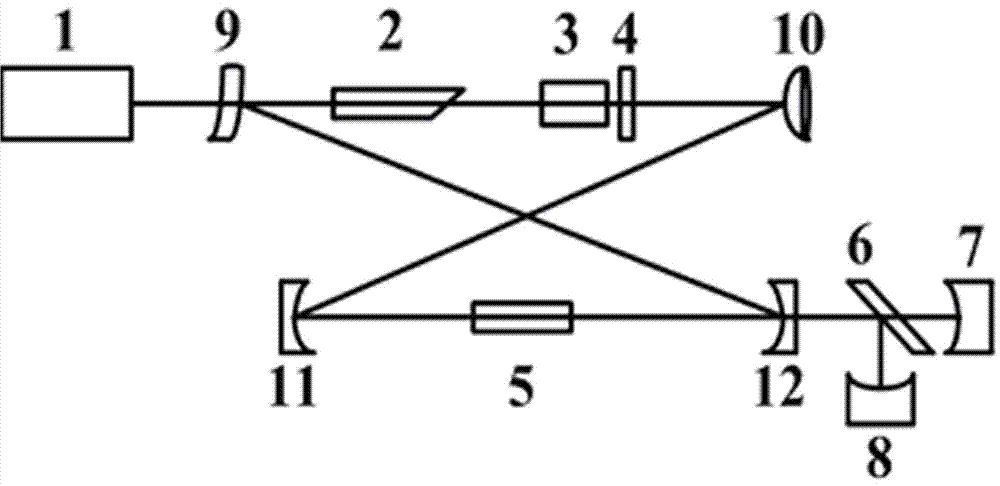

[0038] Implementation mode one: figure 1Shown is the measuring device of the present invention to the linear loss in the high-power four-mirror ring resonator, including pumping source 1, gain crystal 2, ring resonator made up of cavity mirrors (9, 10, 11, 12), set by A one-way device composed of a magneto-optical medium 3 and a half-wave plate 4 in a permanent magnet, a frequency doubling crystal 5, a beam splitter 6, a first power meter 7 and a second power meter 8. The pump light is focused to the center of the gain crystal 2 through the coupling system. The laser adopts a four-mirror ring resonant cavity structure, which is composed of cavity mirrors (9, 10, 11, 12). The cavity mirror 9 is a concave-convex mirror, the concave surface is coated with a high-transmittance film for pump light, and the convex surface is coated with a high-transmittance film for pump light and a high-reflection film for fundamental-frequency light; the cavity mirror 10 is a plano-convex mirror,...

Embodiment approach 2

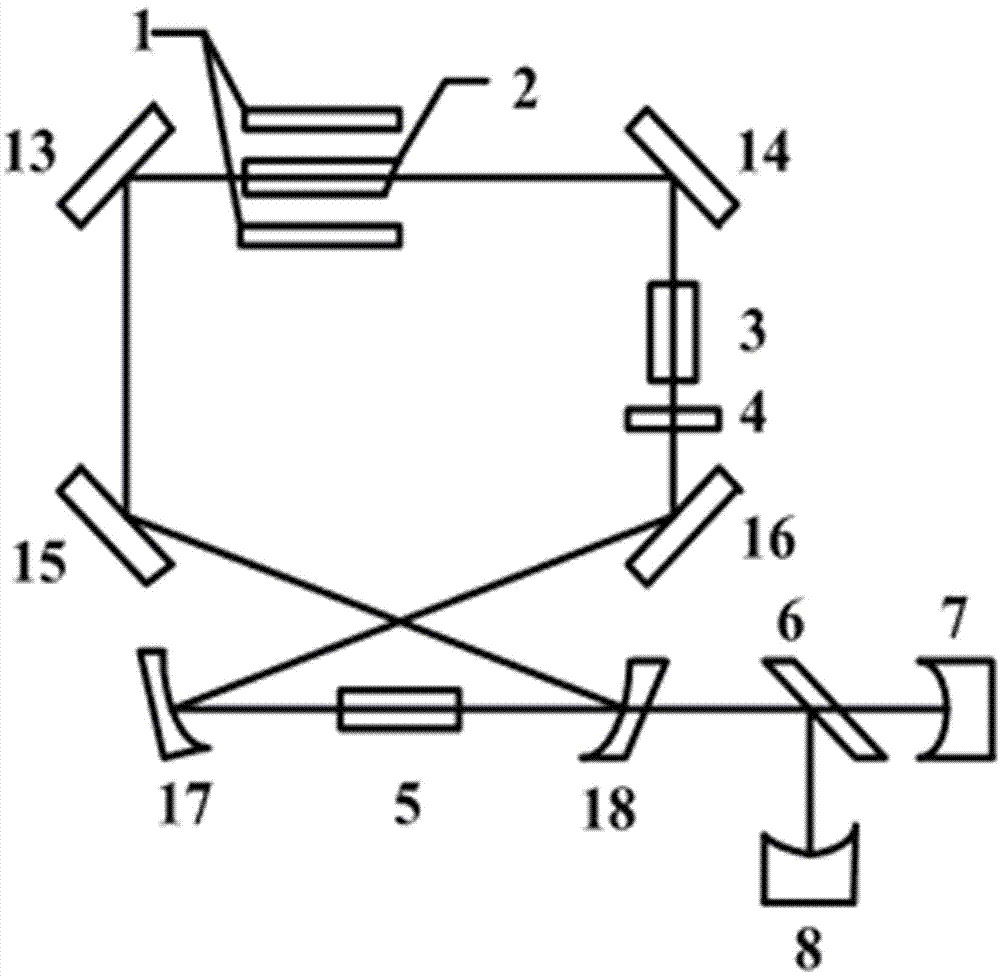

[0039] Implementation mode two: figure 2 Shown is the measurement device of the present invention to the linear loss in the six-mirror annular cavity of laser diode side pump, including pumping source 1, gain crystal 2, by cavity mirror (13, 14, 15, 16, 17, 18) A ring resonant cavity, a one-way device composed of a magneto-optical medium 3 and a half-wave plate 4 placed in a permanent magnet, a frequency doubling crystal 5, a beam splitter 6, a first power meter 7 and a second power meter 8. The light emitted by the pump source 1 is projected onto the gain crystal 2 after shaping and focusing, and the wavelength of the pump light is located at the absorption peak of the gain crystal 2 . The light-transmitting surface of the gain crystal 2 is cut into a certain wedge angle, which acts as a polarization beam splitter and facilitates maintaining the stability of the polarization state of the laser. The resonant cavity is composed of four plane mirrors (13, 14, 15, 16) and two p...

Embodiment approach 3

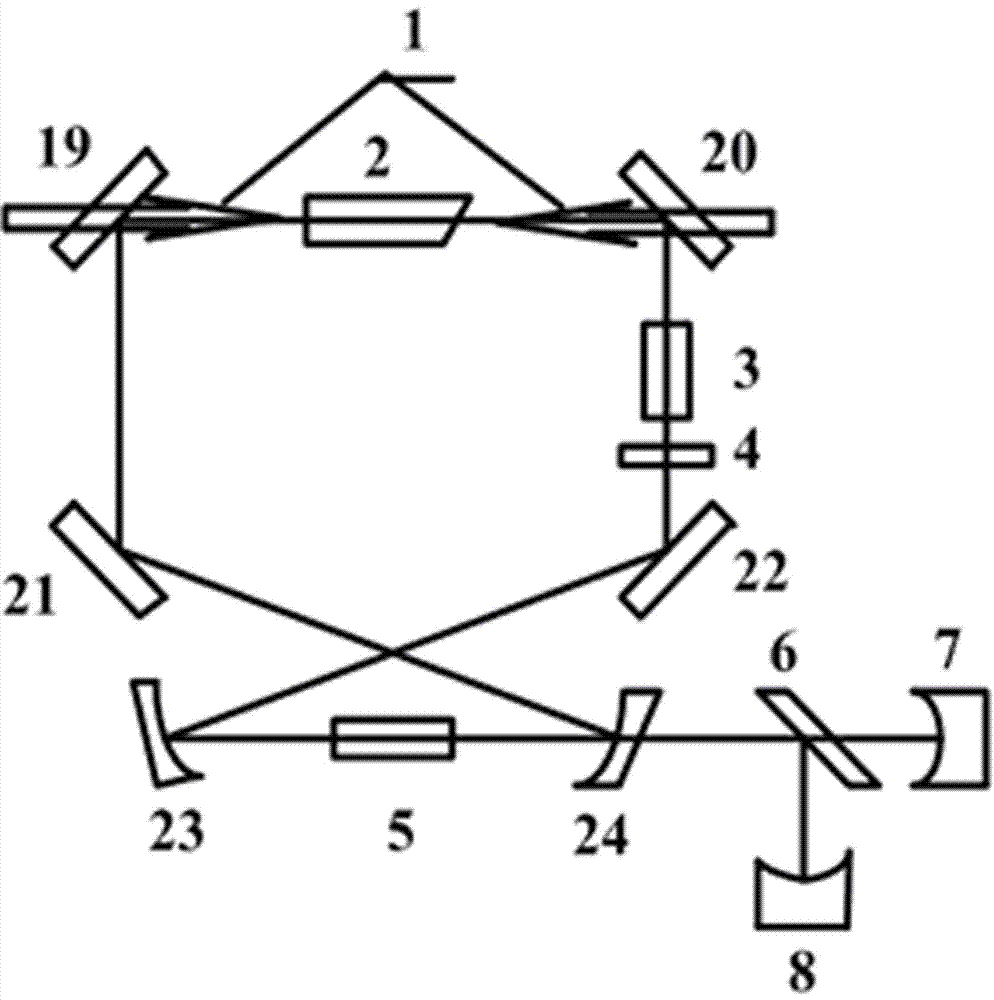

[0040] Implementation mode three: image 3 Shown is the measurement device of the linear loss in the cavity of the six-mirror annular cavity continuous single-frequency laser of the present invention that laser diode double-terminal pumping comprises pumping source 1, gain crystal 2, by cavity mirror (19,20,21,22 , 23, 24) composed of a ring resonant cavity, a one-way device composed of a magneto-optical medium 3 and a half-wave plate 4 placed in a permanent magnet, and a frequency doubling crystal 5. Compared with Embodiment 2, the main difference is that the pumping method is changed from side pumping to double-end pumping. The two end surfaces of the gain crystal 2 and the cavity mirrors 19 and 20 are coated with a high-transmittance film for pump light. The frequency doubling crystal 5 is located at the beam waist of the fundamental mode between the cavity mirror 23 and the cavity mirror 24 to ensure high nonlinear conversion efficiency. The frequency doubling crystal 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com