Method for measuring intra-cavity loss of LD pumping solid state laser device

A solid-state laser and internal loss technology, applied in the field of lasers, can solve problems affecting laser operation and laser output, difficult to guarantee reliability, complex structure, etc., and achieve the effects of easy actual operation, no interference measurement, and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

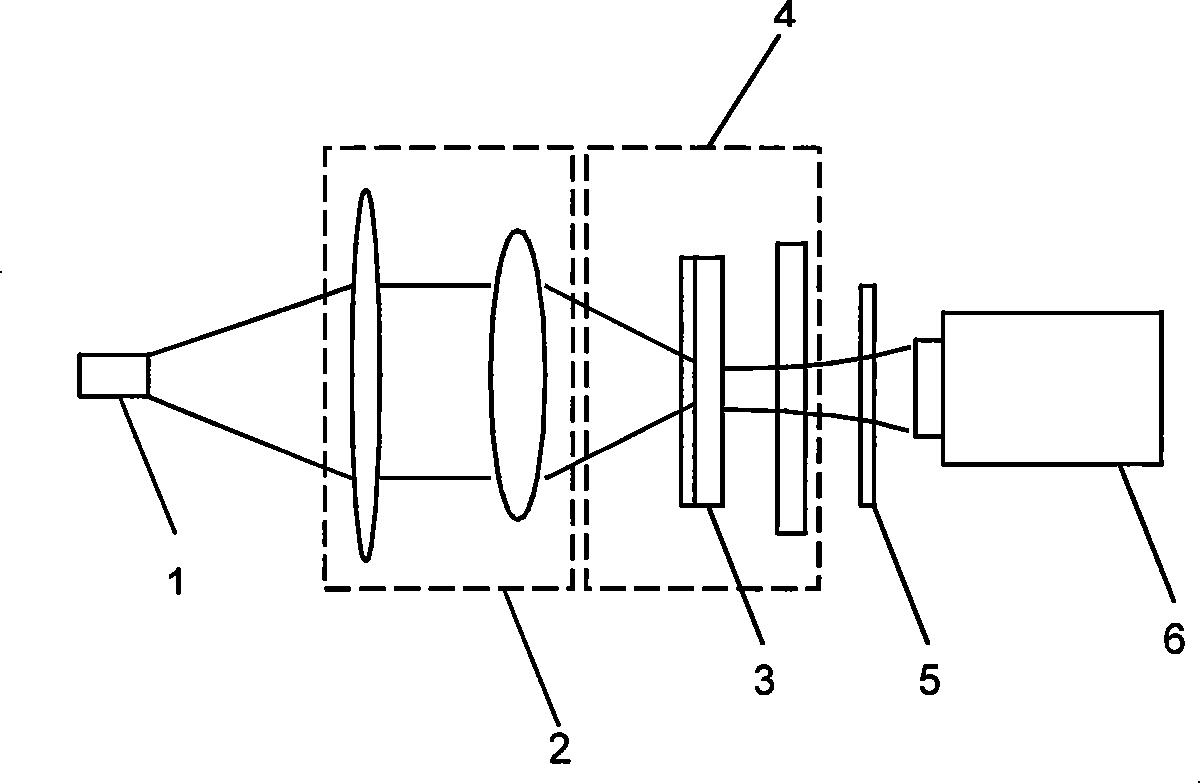

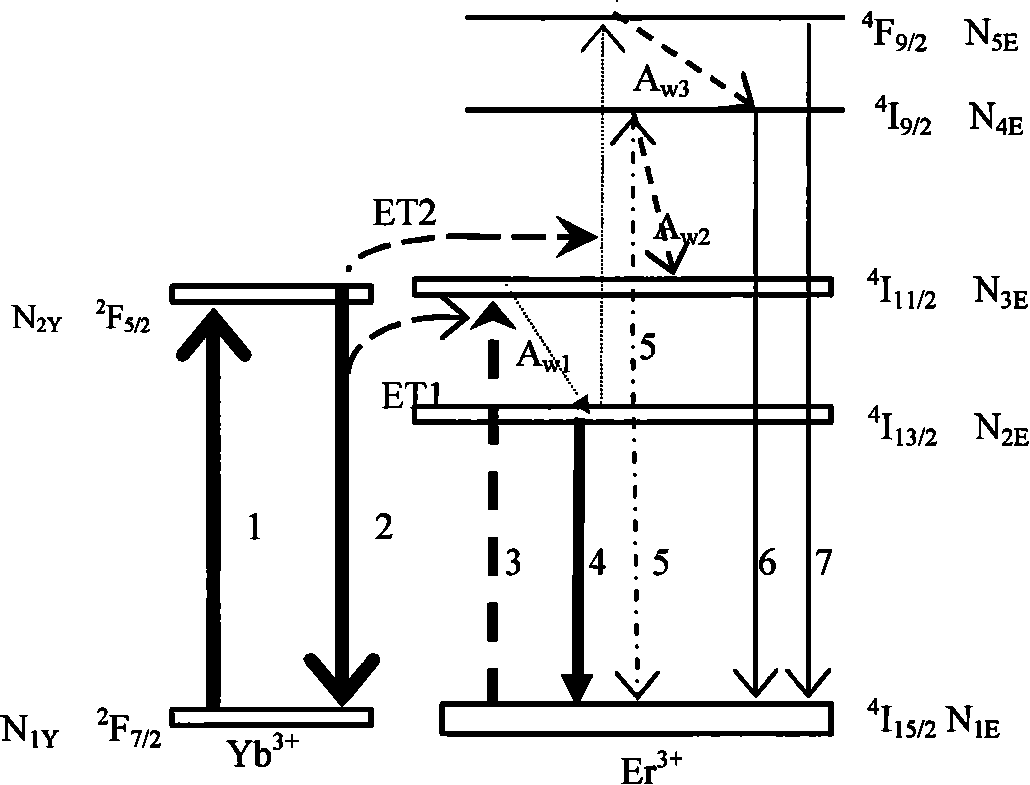

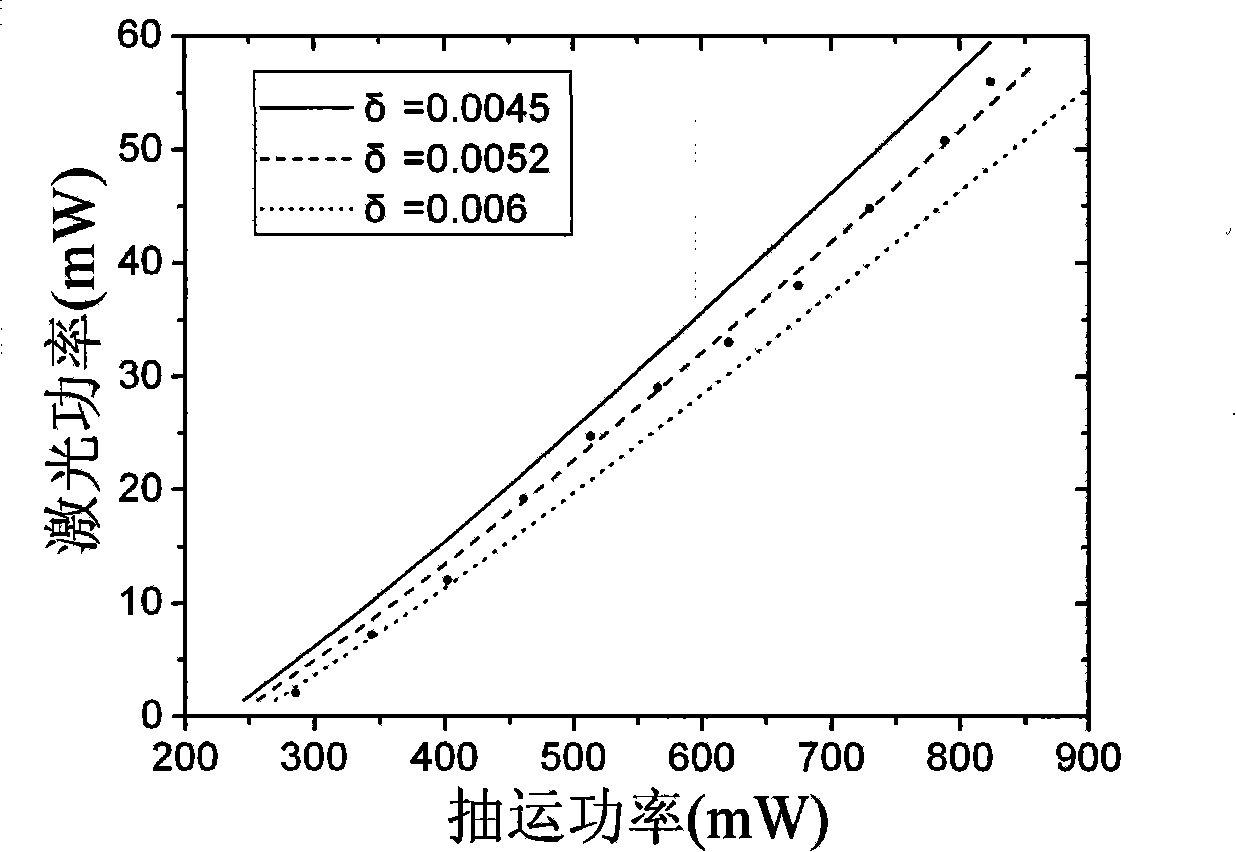

[0037] Example 1: as figure 1 As shown, the implementation device of the present invention includes a pump semiconductor laser 1 , a pump coupling system 2 , a laser medium 3 , a laser flat resonator 4 , a 975 nm filter 5 , and a power meter 6 . The pumping light with a wavelength of 975 nm output by the pumping semiconductor laser 1 passes through the pumping coupling system 2 and is coupled at the laser medium 3 into a fundamental mode Gaussian distribution circular spot with a radius of 75 μm. The laser medium 3 is an erbium-ytterbium co-doped phosphate glass microplate with a thickness of 1mm, and the erbium ion concentration is N e 9.88×10 25 / cm 3 , the ytterbium ion concentration N Y is 2.01×10 27 / cm 3. The stimulated radiation of the laser medium 3 generates light with a wavelength of 1540 nm, which is oscillated in the laser resonator 4 and output as laser light. In this example, the total reflection mirror of the microchip laser resonator is replaced by a 154...

Embodiment 2

[0062] Example 2: This example is basically the same as Example 1, with the exception of Figure 4 As shown in the middle part 4, the curvature radius of the output mirror of the microchip laser resonator is 214mm, the reflectivity is 99%, and the 1540nm high-reflection film coated on the laser medium forms a plano-concave cavity. The energy level and rate equations are analyzed with Example 1 same. In the case of cavity lengths of 4.5, 5.5, and 6.5 mm, the round-trip losses in the flat-concave cavity are 0.0048, 0.0056, and 0.0059, respectively.

Embodiment 3

[0063] Example 3: as Figure 5As shown, the implementation device of the present invention includes a pumping semiconductor laser 1 , a pumping coupling system 2 , a laser medium 3 , a 975nm filter 4 , and a power meter 5 . The pumping light with a wavelength of 975 nm output by the pumping semiconductor laser 1 passes through the pumping coupling system 2 and is coupled at the laser medium 3 into a fundamental mode Gaussian distribution circular spot with a radius of 75 μm. The laser medium 3 is an erbium-ytterbium co-doped phosphate glass microplate with a thickness of 1mm, and the erbium ion concentration is N e 9.88×10 25 / cm 3 , the ytterbium ion concentration N Y is 2.01×10 27 / cm 3 . One side of the laser medium 3 close to the pump coupling system 2 is coated with a total reflection film in the 1.54μm band and an anti-reflection film with a transmittance greater than 85% in the 0.98μm band, and the other side is coated with a coating with a transmittance of 1% in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com