A Transformer Hot Spot Temperature Prediction Method Based on Multi-working Condition Parameter Identification and Optimization

A technology of parameter identification and hot spot temperature, applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve the problem of increasing the risk of transformer over-nameplate operation, the lack of physical meaning of neural network methods, and the multi-transformer heat transfer parameters of thermal circuit models. and other problems, to achieve the effect of improving prediction security, promoting in-depth application, and reliable analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

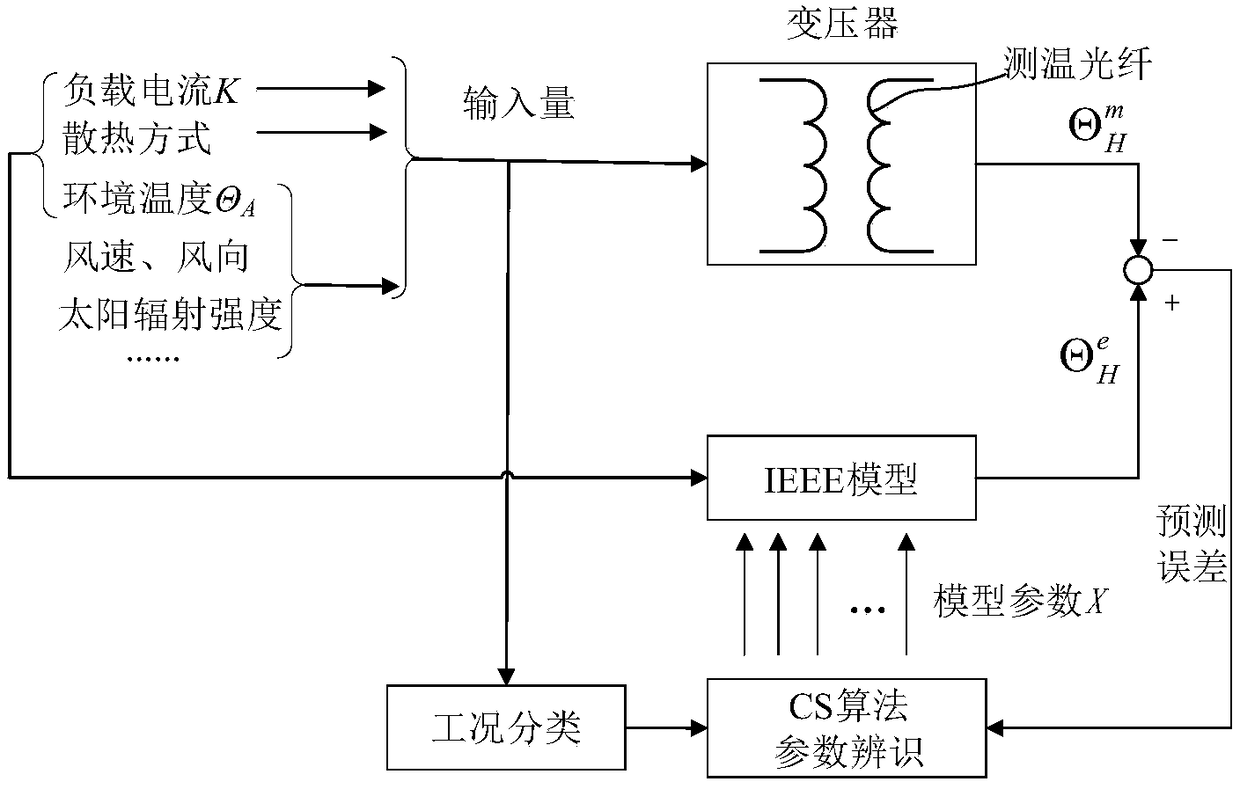

[0038] A transformer hot spot temperature prediction method based on multi-working condition parameter identification optimization, such as figure 1 shown, including:

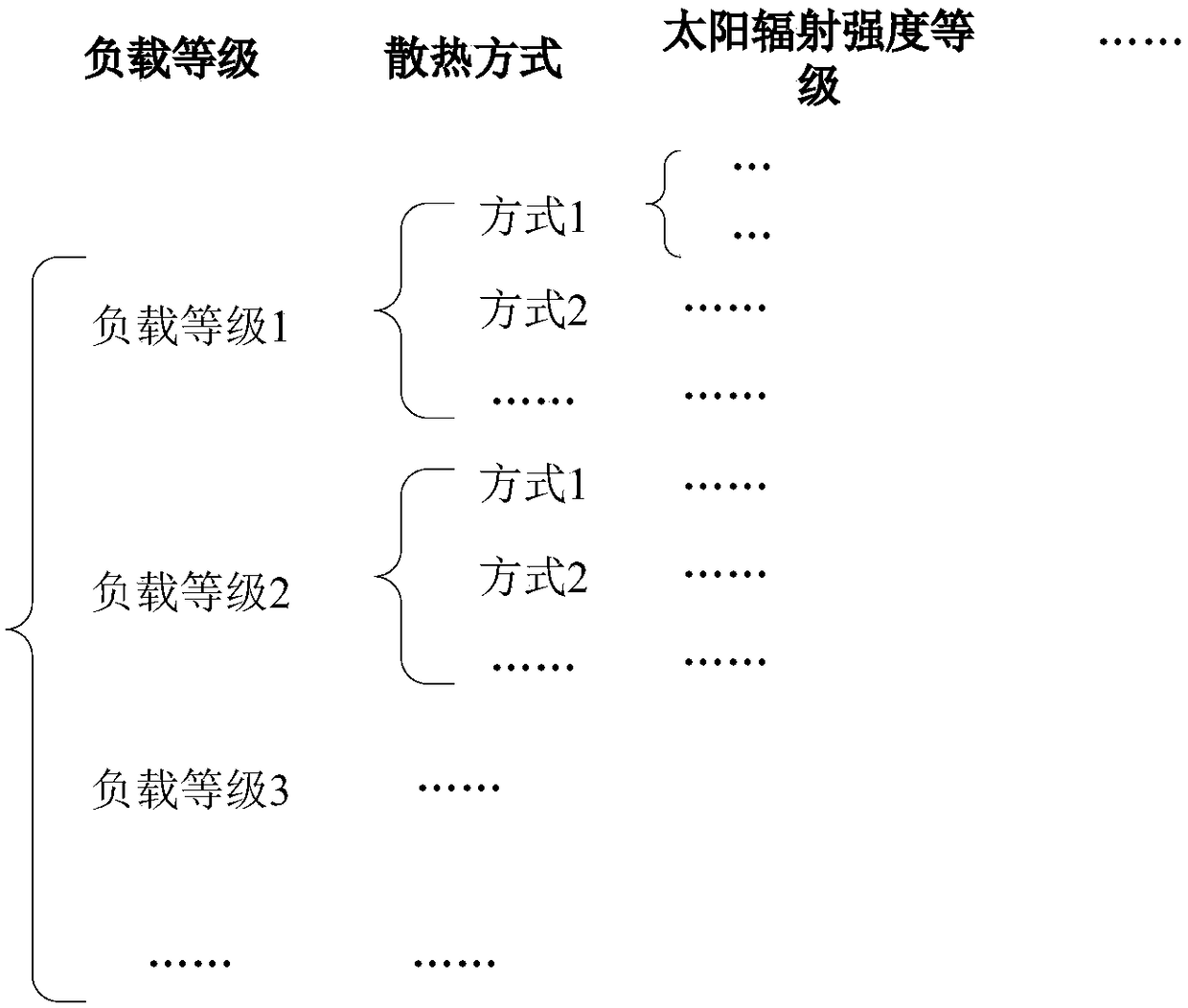

[0039] Step 1: Select the measured data samples of the measured transformer, including load current, ambient temperature, etc.; divide the types of transformer operating conditions according to the measured data, and divide the measured data set for each working condition, and divide the measured data set into a training set and prediction set.

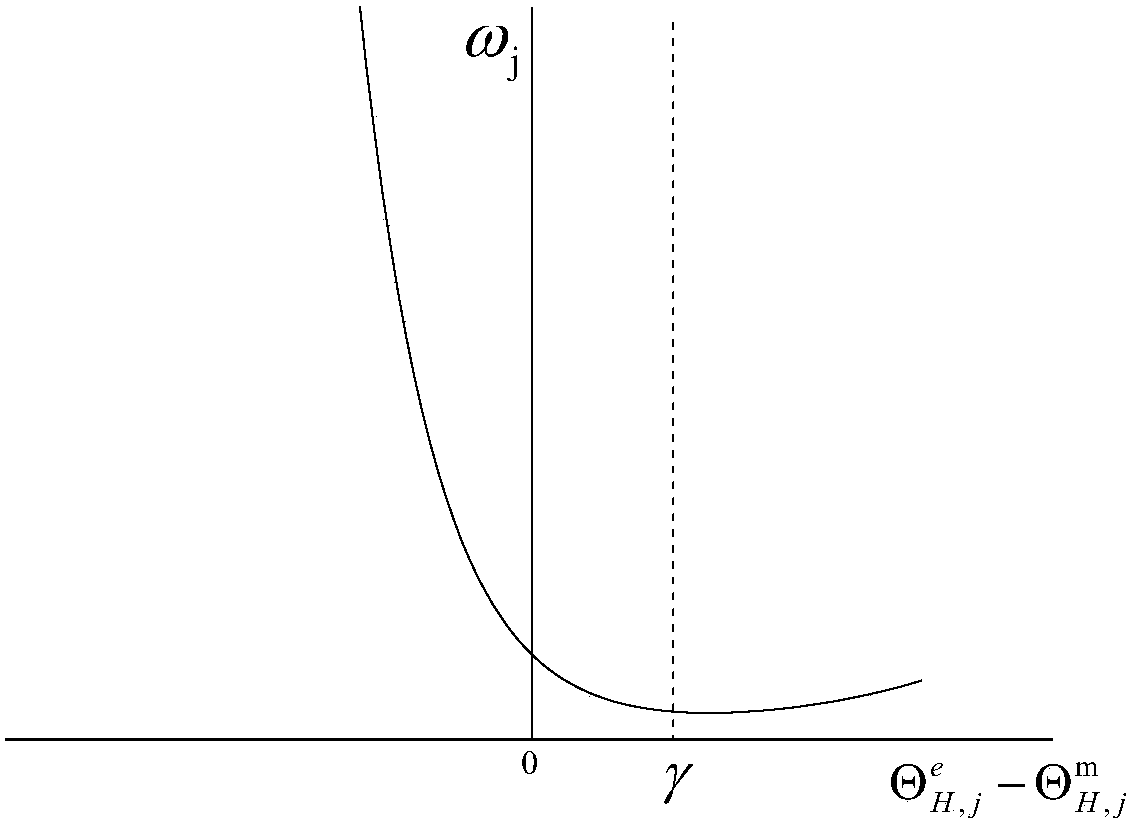

[0040] Step 2: Select the parameters of the IEEE model that vary greatly under different working conditions as the parameters to be identified and optimized; construct the parameter identification optimization objective function of the IEEE model under each working condition.

[0041] Step 3: Using the training set data under each working cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com