Drive Structure of Piezoelectric Injector

A technology of drive structure and oiler, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, machines/engines, generators/motors, etc., can solve the problem of reducing the performance and life of actuators, and the charging current is not easy to be high Accuracy control, can not guarantee the accuracy of the injector and other issues, to achieve the effect of benefiting stability and improving EMC capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings.

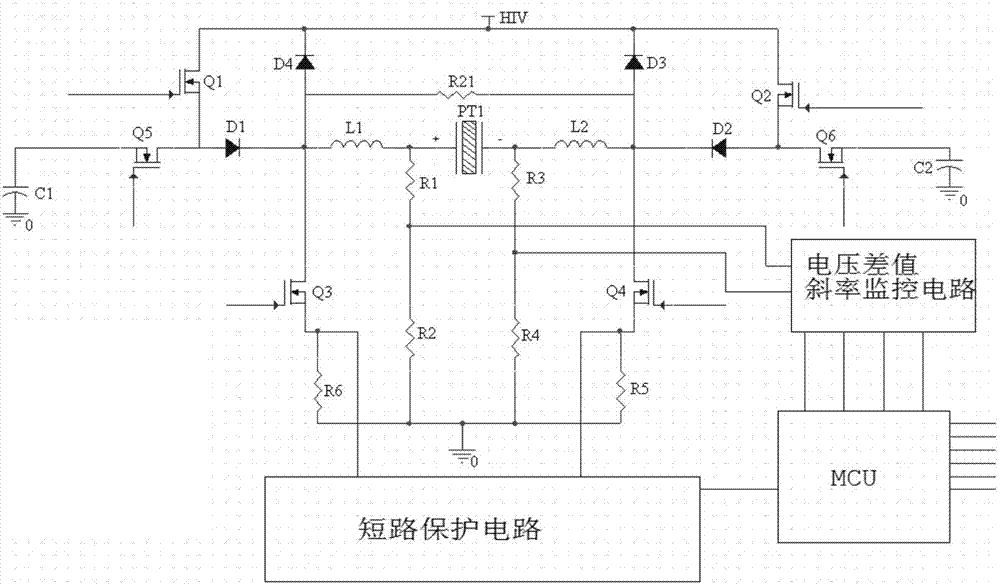

[0024] Such as figure 1 As shown, the present invention includes an actuator drive circuit module, a processor MCU, a voltage difference slope monitoring circuit and a short circuit protection circuit;

[0025] The actuator drive circuit module includes an actuator PT1, the high-voltage end of the actuator PT1 is connected to one end of the inductor L1 and one end of the resistor R1, and the other end of the inductor L1 is connected to the cathode end of the diode D1, the anode end of the diode D4, and the switching tube The drain terminal of Q3 is connected to one end of the resistor R21, the anode terminal of the diode D1 is connected to the source terminal of the switch tube Q1 and the drain terminal of the switch tube Q5, and the drain terminal of the switch tube Q1 is connected to the high voltage source HIV and the cathode terminal of the diode D4, The source end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com