A pre-cutter for beam pulse control

A pre-cutting and beam current technology, which is applied in accelerators, electrical components, etc., can solve the problems of difficult manufacturing of pre-cutters, high price, and difficult realization of power supplies, and achieve the effect of reducing the difficulty of power supply manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

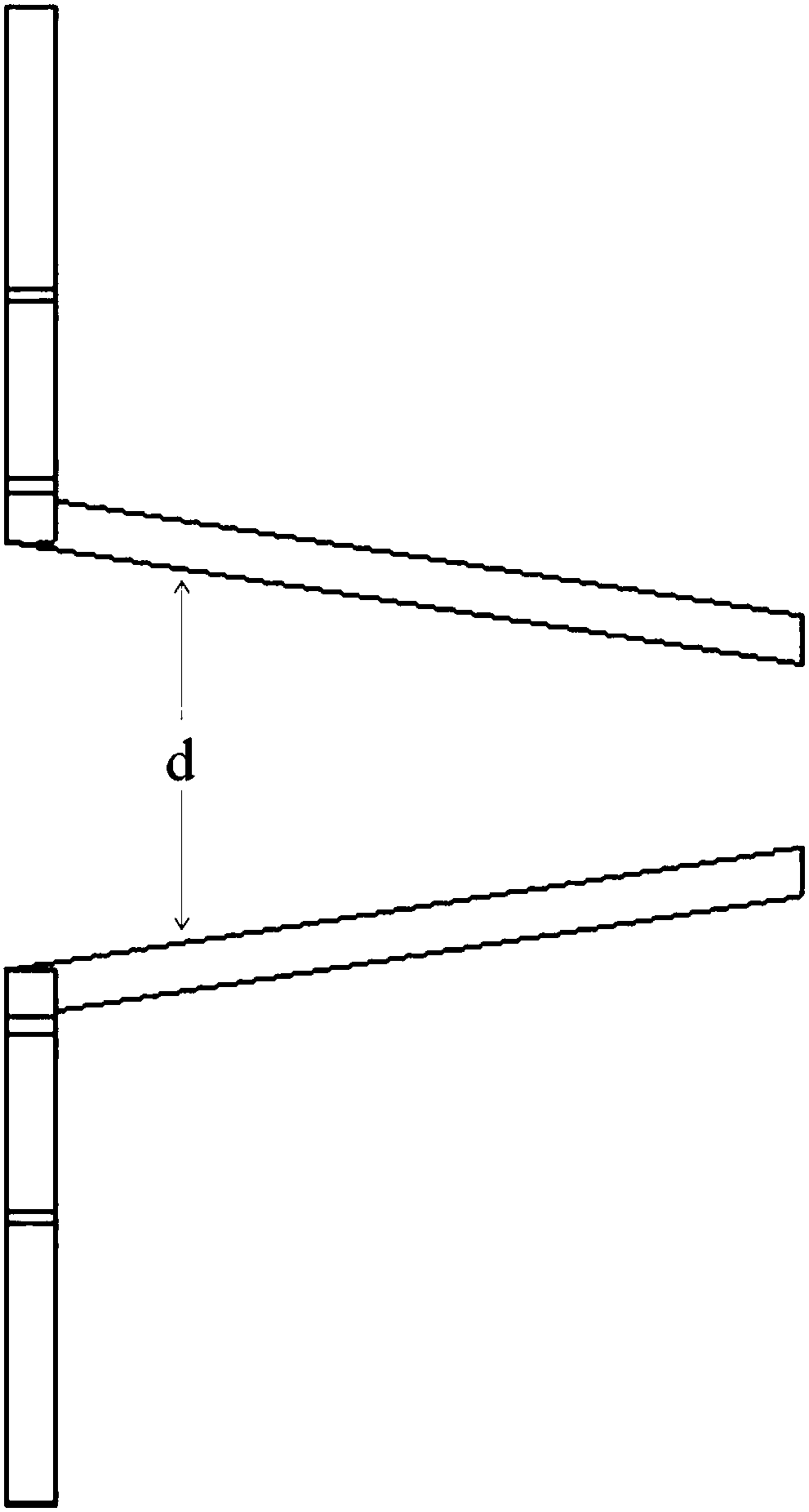

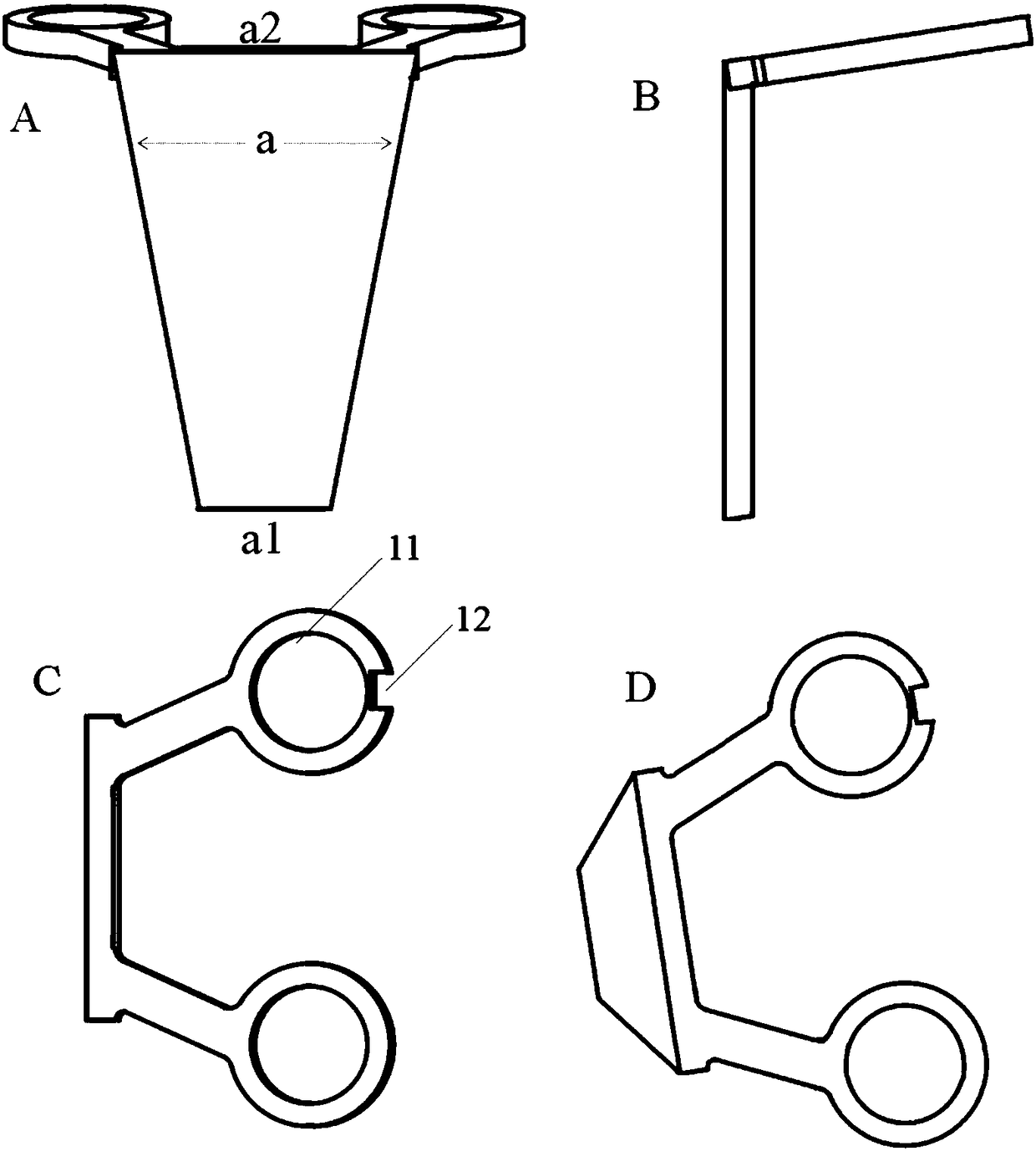

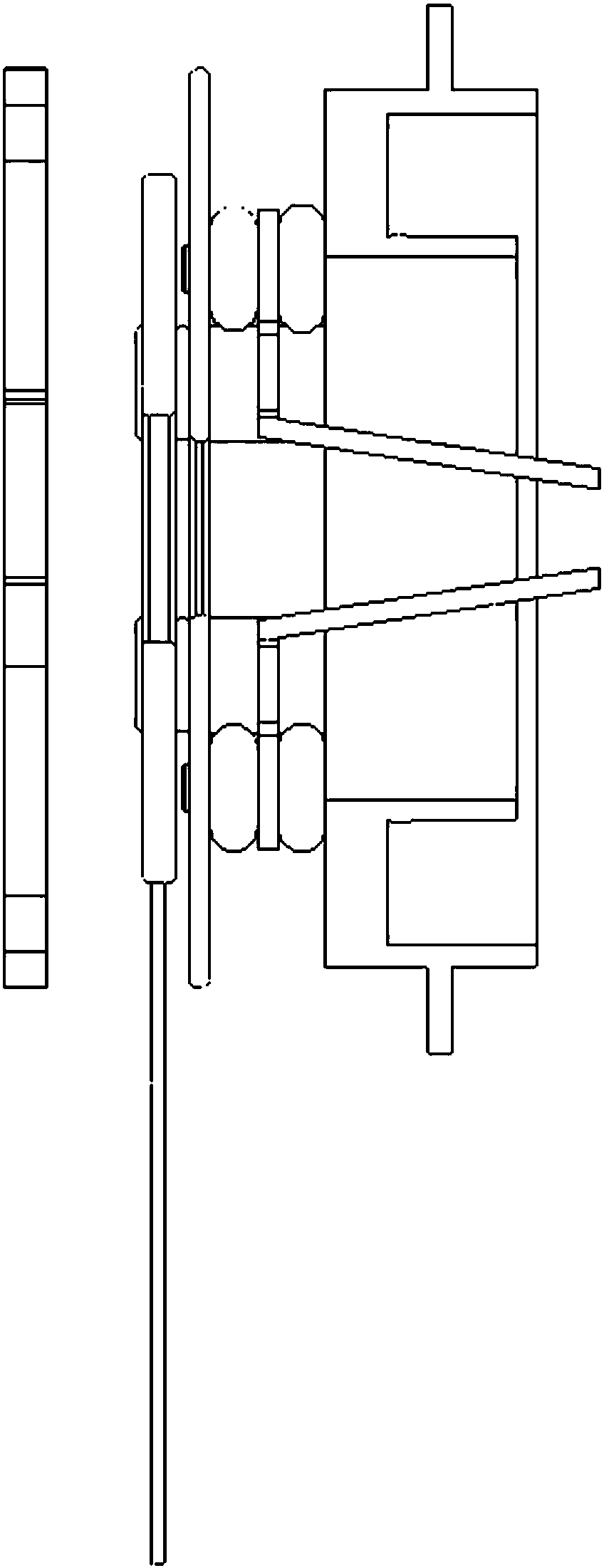

[0043] The pre-beam cutter in this example includes an electrostatic deflection plate installed at the end of a low-energy transmission line with a magnetic focus and matching structure, a power supply that provides voltage for the electrostatic deflection plate, and accessories used with the electrostatic deflection plate; the electrostatic deflection plate consists of two The flat electrode plate is composed of two electrode plates that are mirror-image symmetrically installed, and the width and installation distance of the two electrode plates are linearly changed in a positive correlation with the diameter of the beam envelope. Because the spallation neutron source is a huge project, in order to save time for installation and system testing, this example uses simulation calculations to set the same beam shape and load the same voltage to compare parallel plate electrodes and inclined plate electrodes. , The deflection effect of the semi-cylindrical electrode. Among them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com