Electrode core for point welding machine

A technology of electrode core, spot welding machine, applied in the direction of electrode features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

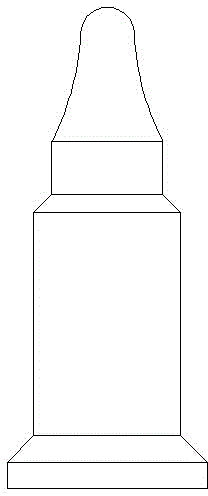

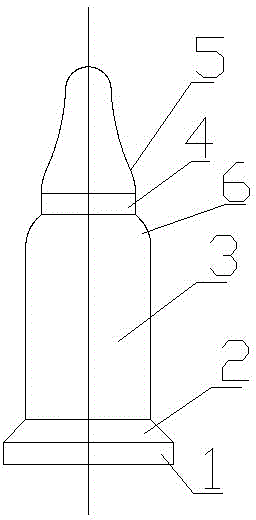

[0021] An electrode core for a spot welding machine, comprising a first oblate cylinder part 1, a circular frustum part 2, a long cylinder part 3, a second oblate cylinder part 4, and an electrode head 5 arranged in sequence.

[0022] A rounded corner 6 is provided between the top plate and the side wall of the long cylindrical part.

[0023] The rounding radius R is 3.5mm.

[0024] The diameter of the lower base of the truncated circular portion is equal to the diameter of the first oblate cylindrical portion, the diameter of the upper base of the circular truncated portion is equal to the diameter of the long cylindrical portion, and the diameter of the second flat cylindrical portion is smaller than the diameter of the long cylindrical portion. The bottom diameter of the electrode tip is smaller than the diameter of the second oblate cylinder part, and the diameter of the electrode tip gradually decreases from the second oblate cylinder part to the end of the electrode tip....

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com