Support member, image carrier and image forming device

A technology of image carrier and supporting parts, which is applied in the direction of electric recording process applying charge pattern, equipment and instrument of electric recording process applying charge pattern, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

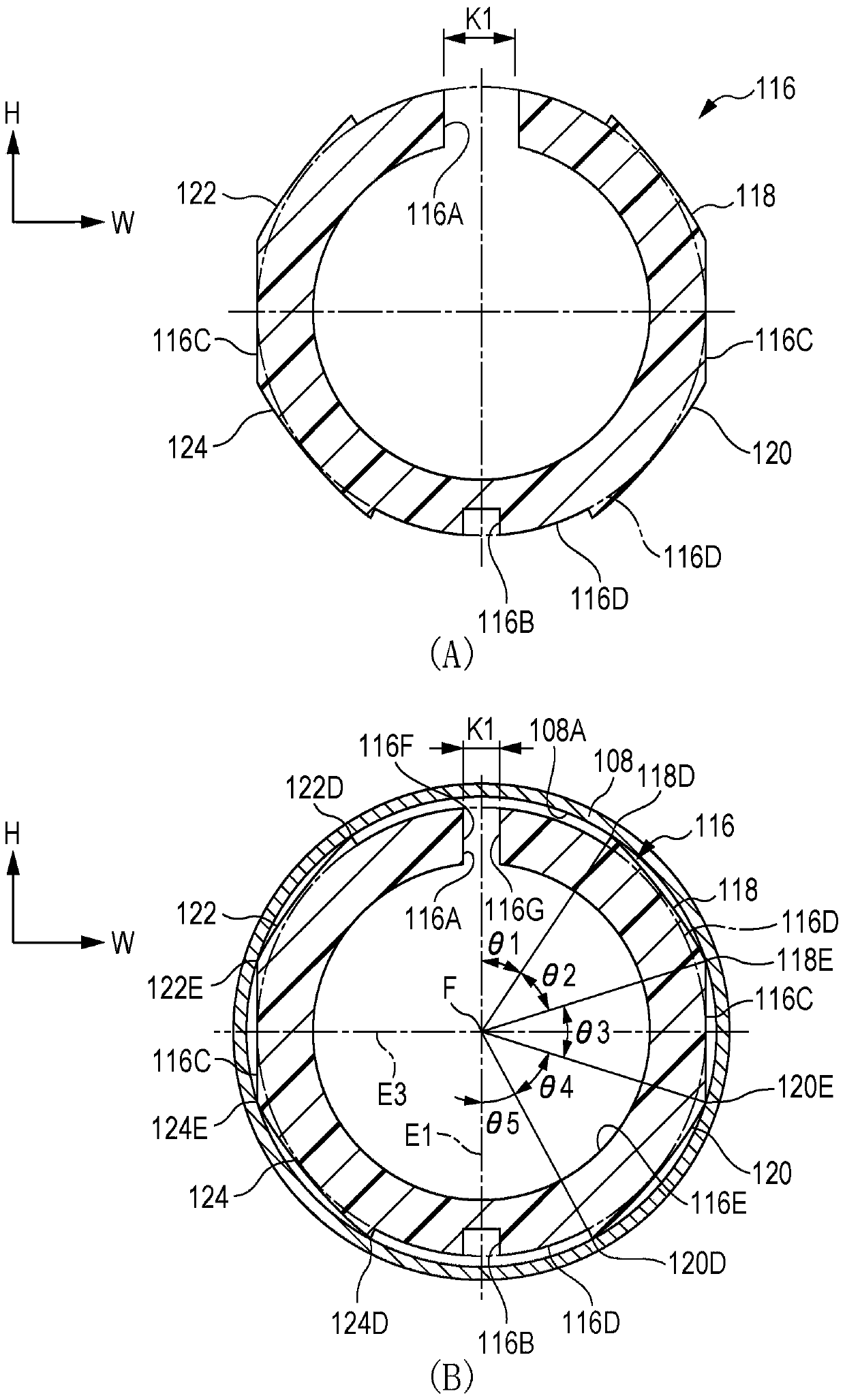

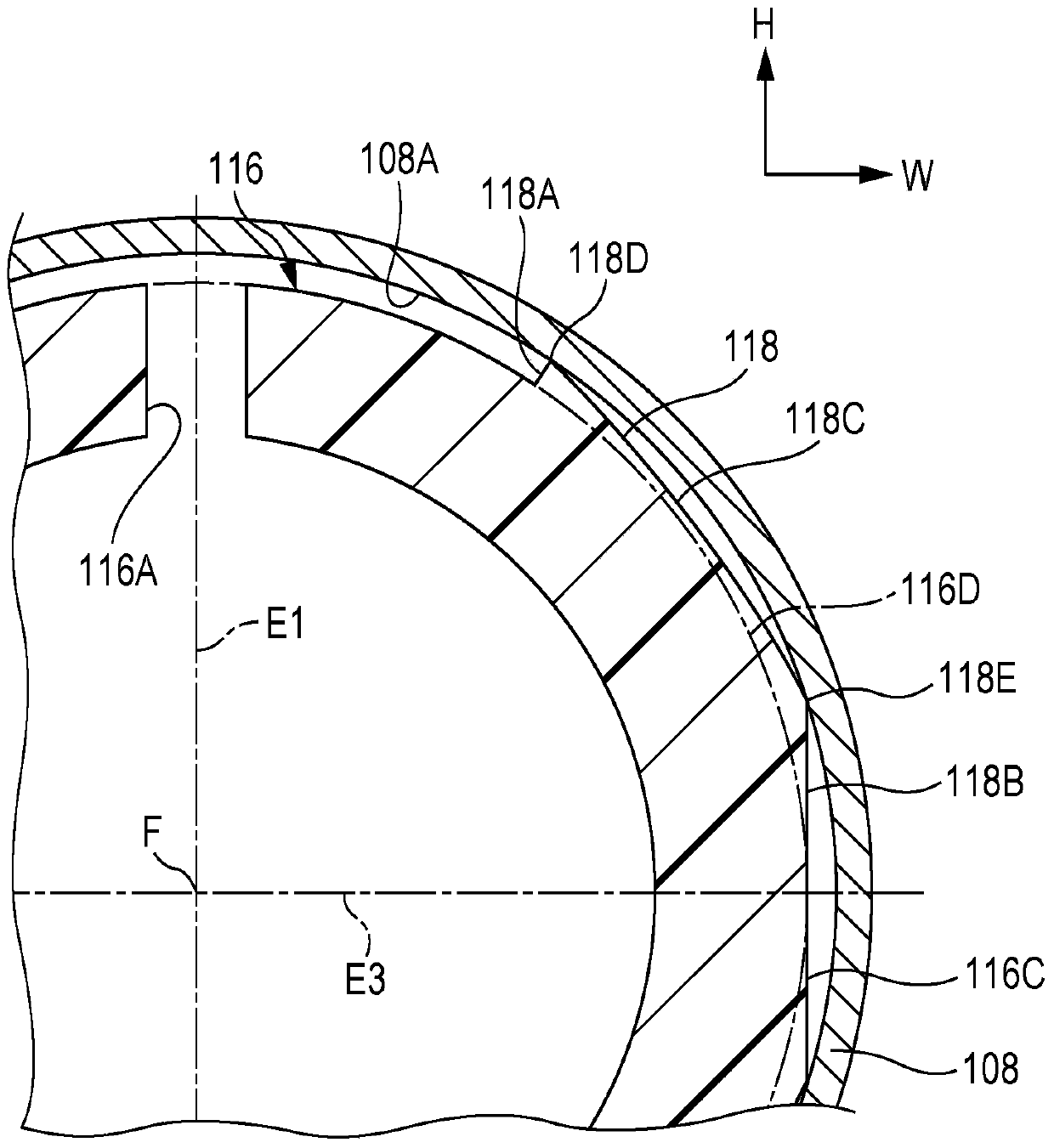

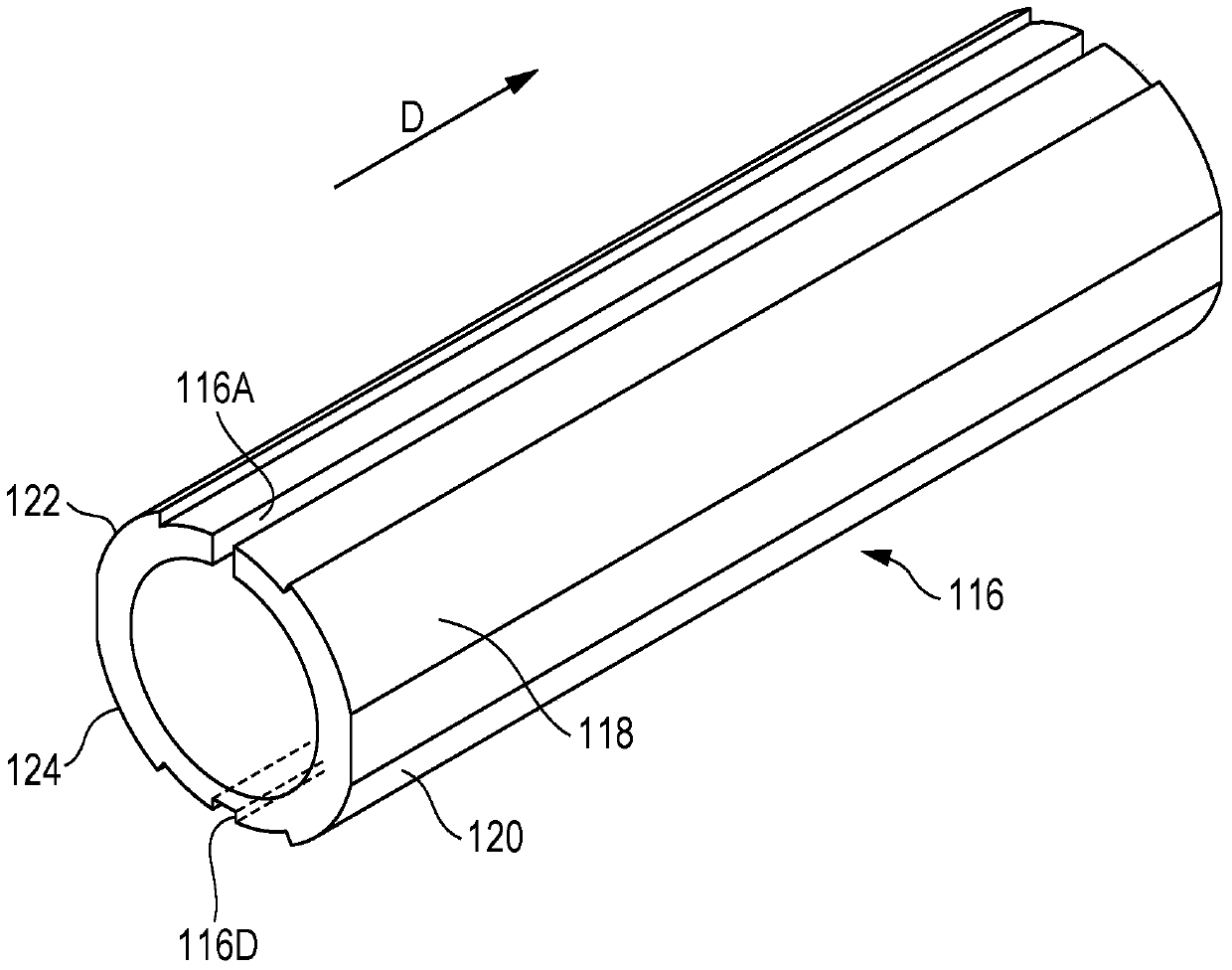

[0073] reference Picture 12 The supporting member 116 according to the first embodiment may be fitted to the cylindrical body 108 so that the supporting member 116 is supported in the central region of the cylindrical body 108 in the device depth direction.

[0074] The supporting member 116 is made of a resin material. Such as figure 1 As shown in (A) and (B) of, the support member 116 is arc-shaped and includes ends where a gap 116A is provided and opposed to each other. The gap 116A is formed in the support member 116 so as to extend in the axial direction at a specific position in the circumferential direction. In the first embodiment, the support member 116 is made of acrylonitrile-butadiene-styrene (ABS) resin. The wall thickness of the supporting member 116 is 4 mm, and the length of the supporting member 116 in the device depth direction is 100 mm.

[0075] Such as figure 1 As shown in (B), in the state where the supporting member 116 is supported in the cylindrical body...

no. 2 example

[0089] The support member 136 according to the second embodiment is described below. The difference between the support part 136 and the support part 116 will be mainly described below.

[0090] in Figure 4 In (B), the outer peripheral surface 136D of the support member 136 according to the second embodiment is represented by a chain line and a solid line, which extends in the depth direction of the device. In a state in which the support member 136 is provided in the cylindrical body 108, the outer peripheral surface 136D is a circular surface when viewed in the depth direction of the device. The outer peripheral surface 136D partially includes an imaginary surface.

[0091] In a state where the support member 136 is supported in the cylindrical body 108, when viewed in the device depth direction, the support member 136 includes a pair of flat portions 136C that are symmetrical to each other with respect to the straight line E1. Such as Figure 4 As shown in (A) and (B), the fl...

no. 3 example

[0102] The support member 156 according to the third embodiment is described below. The difference between the support part 156 and the support part 116 will be mainly described below.

[0103] in Image 6 In (B), the outer peripheral surface 156D of the support member 156 according to the third embodiment is represented by a chain line and a solid line, which extends in the depth direction of the device. In a state where the support member 156 is provided in the cylindrical body 108, when viewed in the depth direction of the device, the outer peripheral surface 156D is a circular surface, and the outer peripheral surface 156D partially includes an imaginary surface.

[0104] In a state where the support member 156 is supported in the cylindrical body 108, when viewed in the device depth direction, the support member 156 includes a pair of flat portions 156C symmetrical to each other with respect to the straight line E1. Such as Image 6 As shown in (A) and (B), the flat portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com