Stamping waste silent transmission device and transmission method

A technology for conveying devices and waste materials, which is applied in the direction of feeding devices, stripping devices, positioning devices, etc., can solve the problems that cannot be eliminated, eliminate noise sources, etc., and achieve the effects of eliminating sliding noise, eliminating noise, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

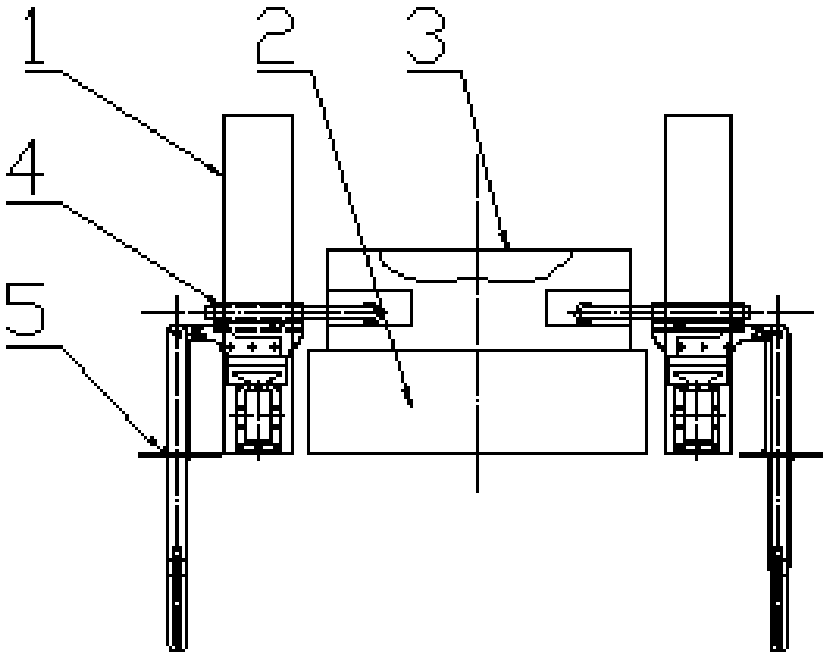

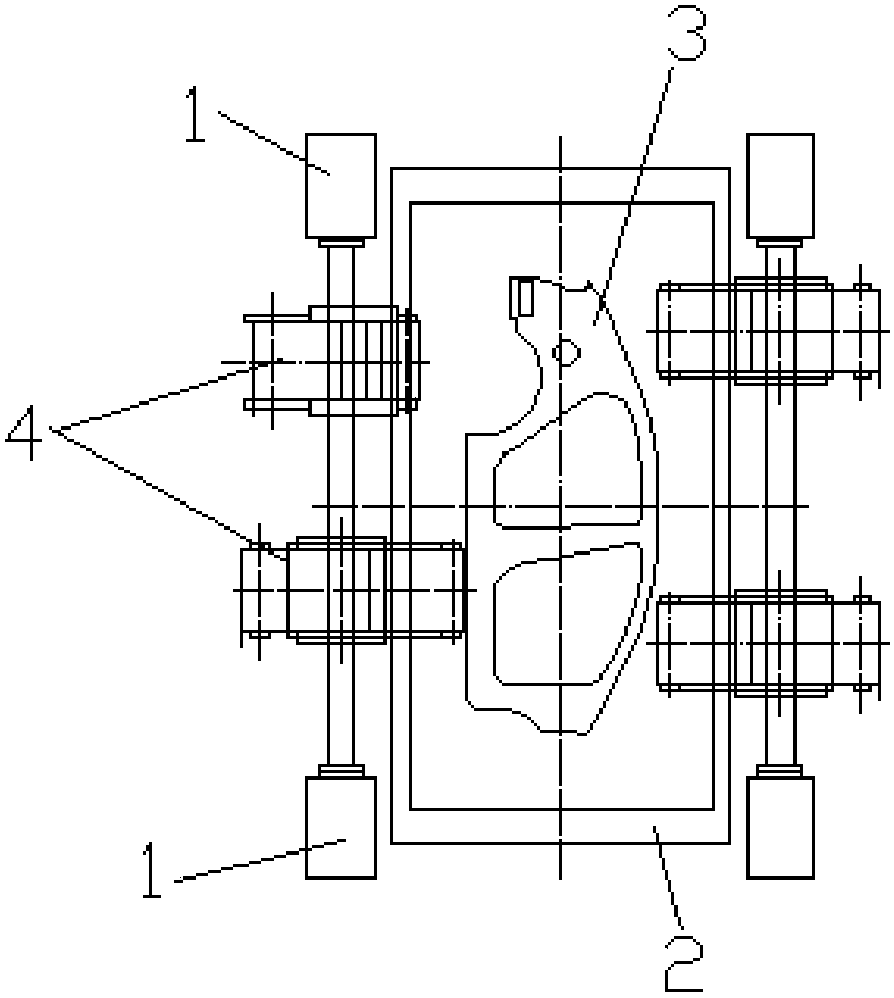

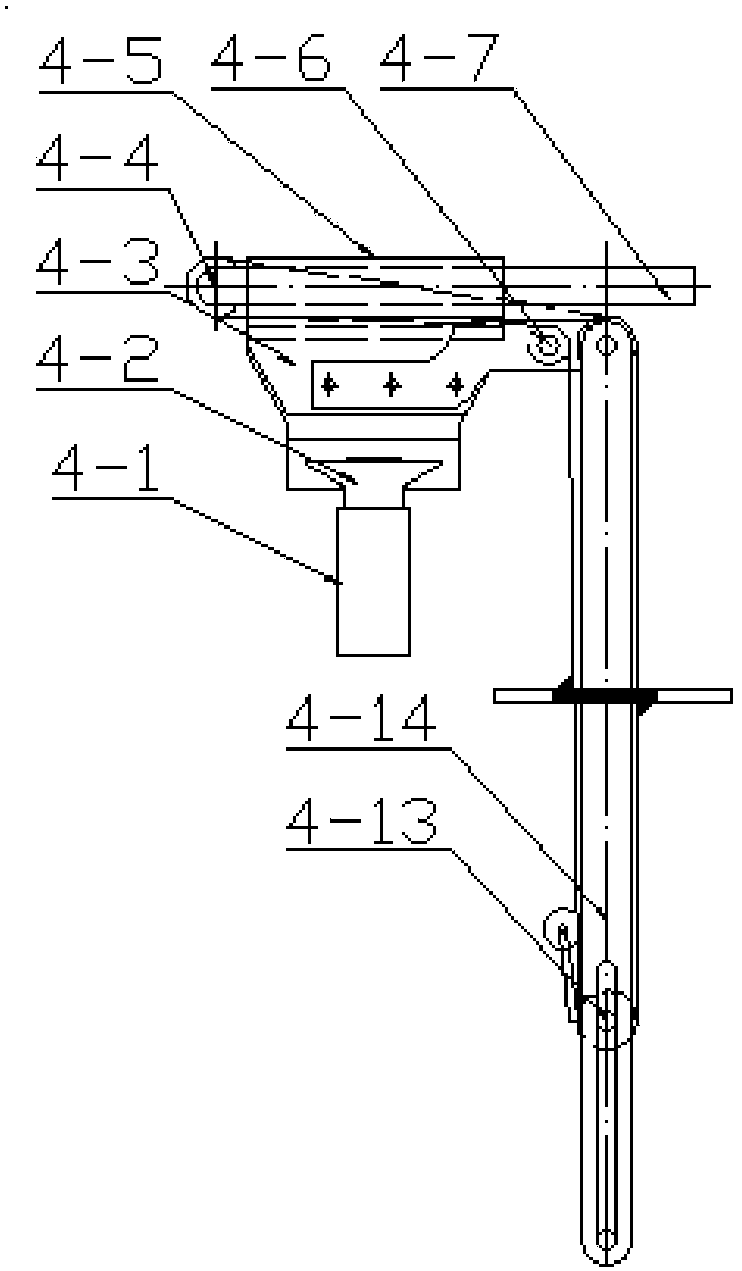

[0027] like Figure 1-Figure 4 As shown, the silent conveying device for stamping waste includes a silent conveying mechanism 4 arranged on the front and rear sides of the press. The silent conveying mechanism 4 includes a beam 4-1 between the columns 1 of the press and a beam 4-1 The upper base 4-3 can slide along the beam 4-1, and the base 4-3 is used as the basic skeleton; the base 4-3 is provided with a conveying mechanism that can telescopically move and transfer stamping waste; the foundations on the front and rear sides of the press Sealing and sound-insulating brushes 5 are respectively arranged on the top; the lower end of the conveying mechanism passes through the sealing and sound-insulating brushes 5 and extends into the waste pit below the press. The base 4-3 moves to the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com