Thread tensioning mechanism for conveyance belt

A thread tensioning and conveyor belt technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of affecting transmission efficiency, prone to breakage, affecting transmission effect, etc., and achieves the effect of easy realization, simple structure and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

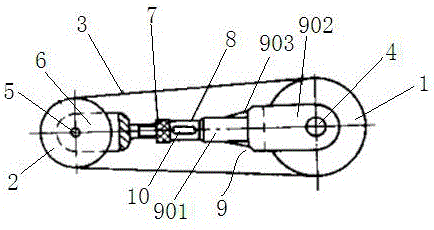

[0016] like figure 1 As shown, the thread tensioning mechanism for the conveyor belt of the present invention includes a driving wheel 1 and a driven wheel 2, the driving wheel 1 and the driven wheel 2 are sleeved with a conveyor belt 3, and the center of the driving wheel 1 is provided with The main drive bearing 4 and the center of the driven wheel 2 are provided with a slave drive bearing 5, the main drive bearing 4 and the slave drive bearing 5 are on the same level, and the first connecting rod 6 is sleeved on the slave drive bearing 5, The first connecting rod 6 is screwed to one end of the directional key 8 through a locknut 7, and the other end of the directional key 8 is fixedly connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap