Concentric dual clutch device

A dual-clutch, clutch technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of small axial total length, large axial total length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

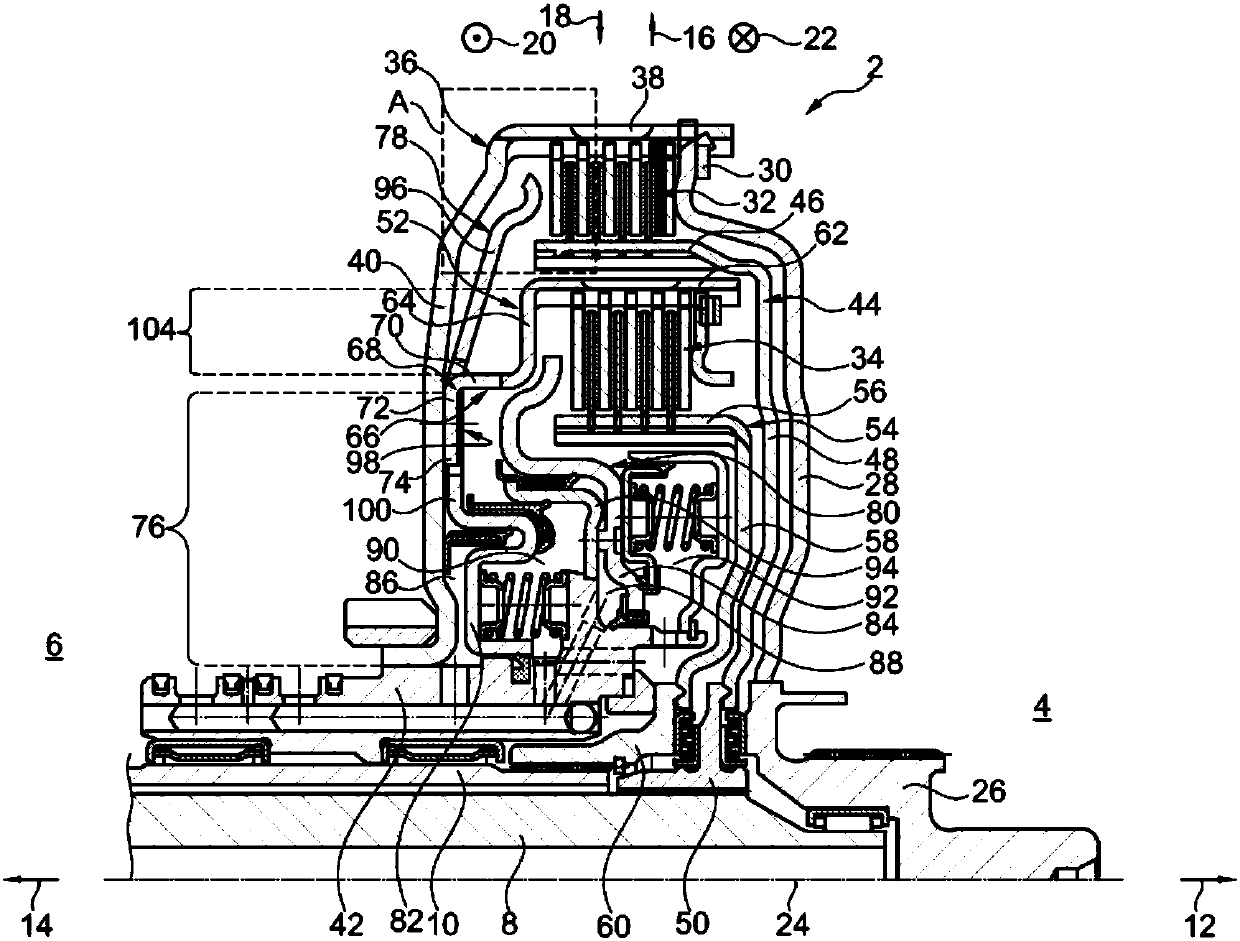

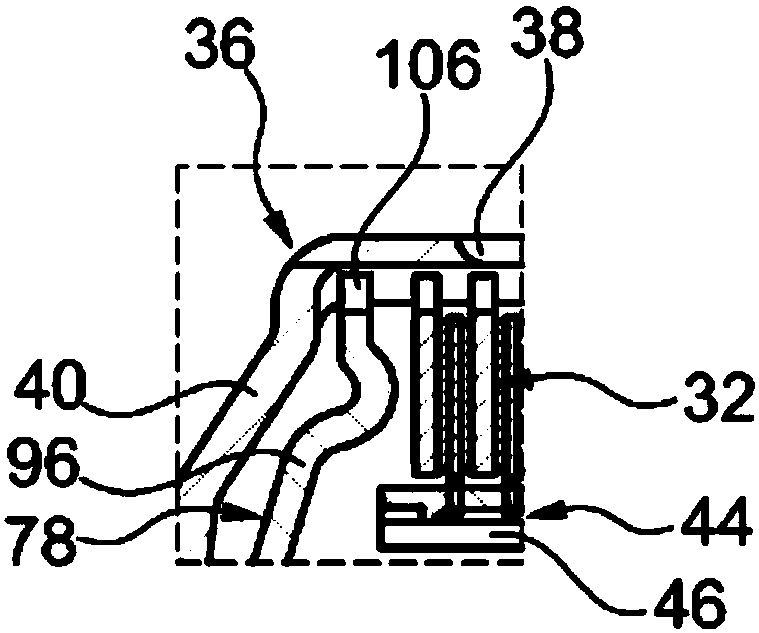

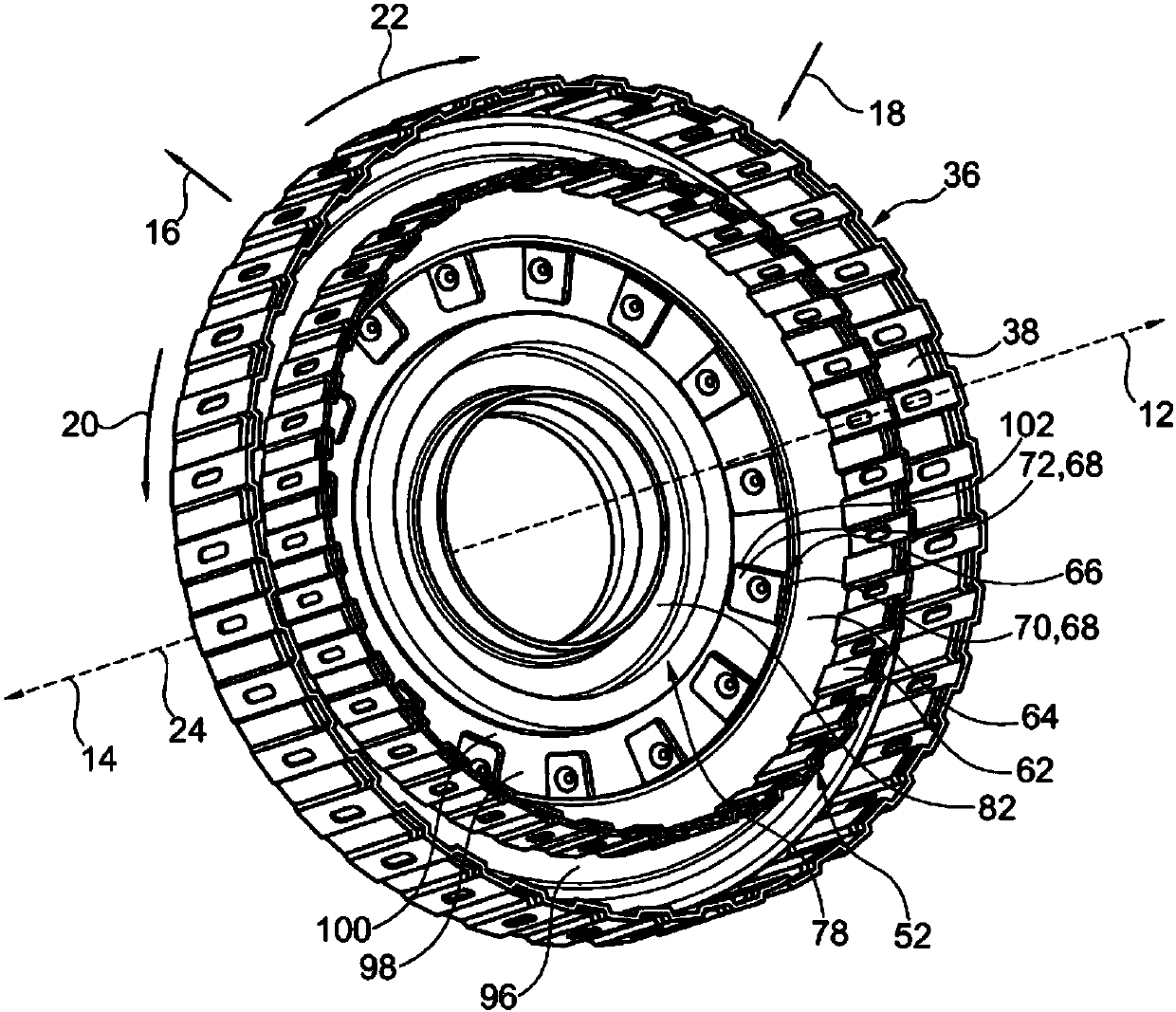

[0032] figure 1 A concentric dual clutch arrangement 2 is shown for arrangement in the drive train of a motor vehicle between a drive unit 4 , preferably an internal combustion engine, and a transmission 6 , wherein the drive unit 4 and the transmission 6 are only indicated schematically. The other parts of the transmission 6 shown are a first transmission input shaft 8 and a second transmission input shaft 10, wherein the second transmission input shaft 10 is designed as a hollow shaft through which the first transmission input shaft 8 extends, and They can therefore also be referred to as concentrically arranged transmission input shafts 8 , 10 . In the figures, mutually opposite axial directions 12, 14, mutually opposite radial directions 16, 18 and mutually opposite circumferential directions 20, 22 of the dual clutch device 2 are indicated by means of corresponding arrows, wherein the circumferential directions 20, 22 are also This can be referred to as a rotational dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com