Hydrostatic drive system with pump-sided division of the amount of hydraulic fluid for two hydraulic circuits

A technology of hydraulic fluid and transmission system, applied in the direction of fluid transmission, transmission, transmission control, etc., can solve the problems of long axial total length and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

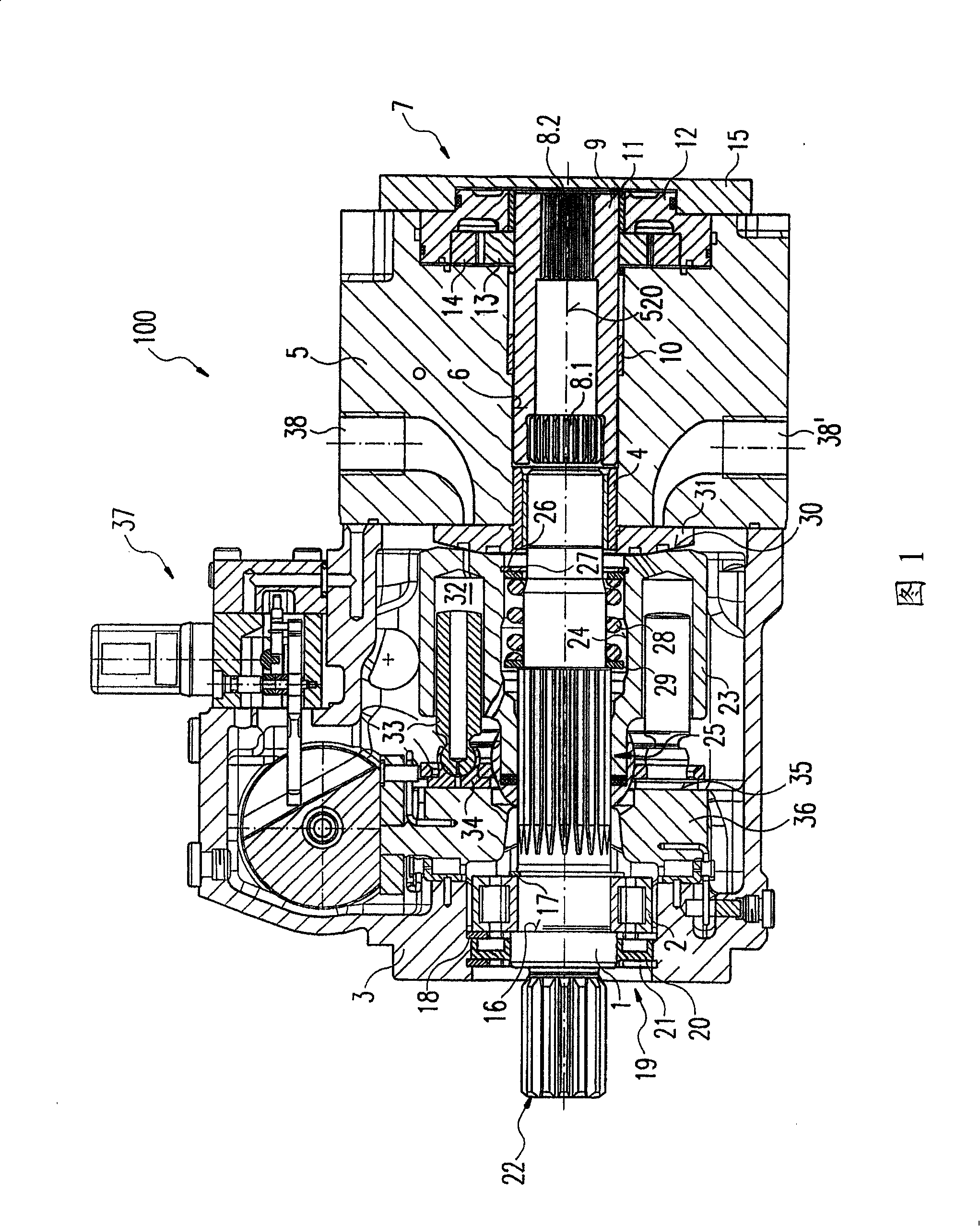

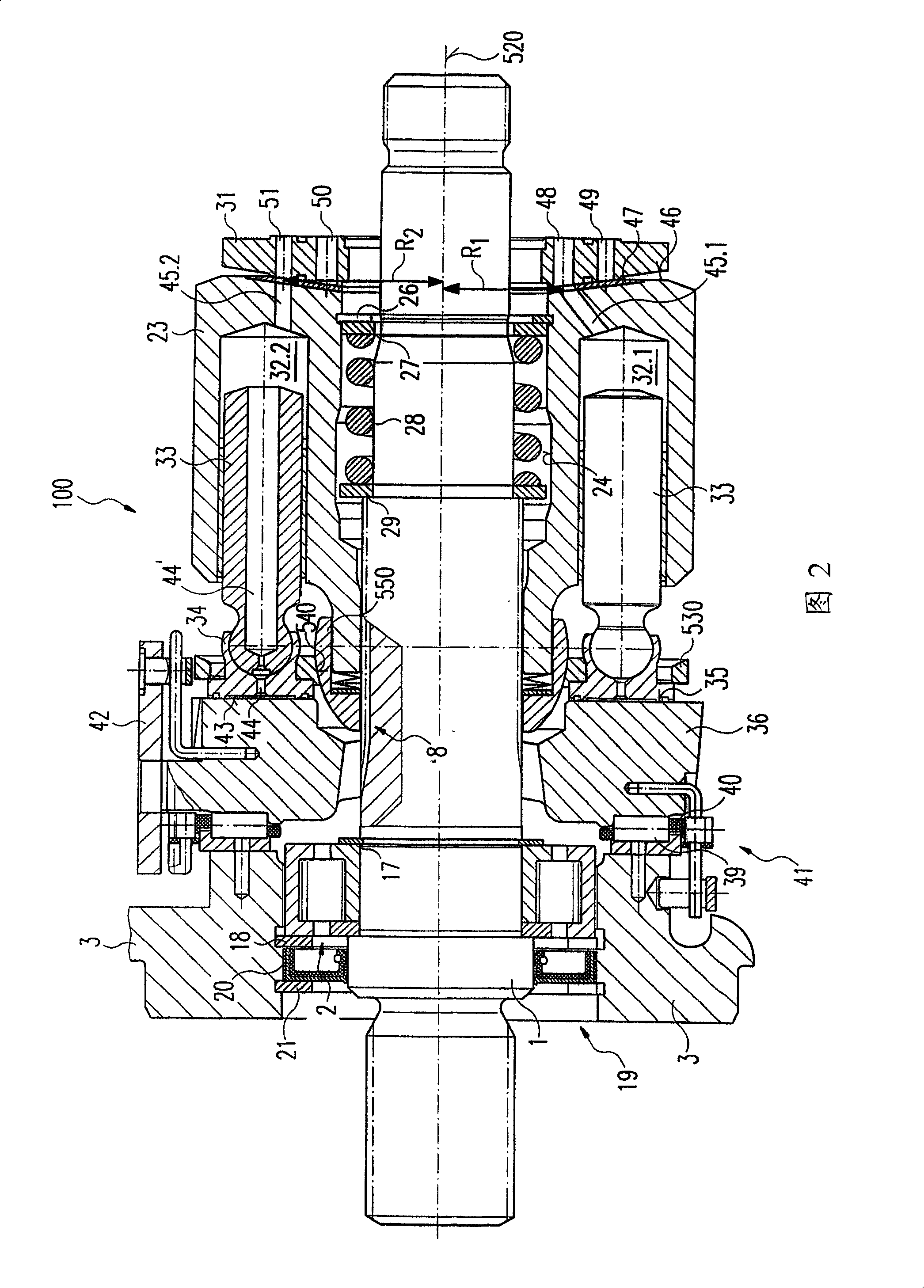

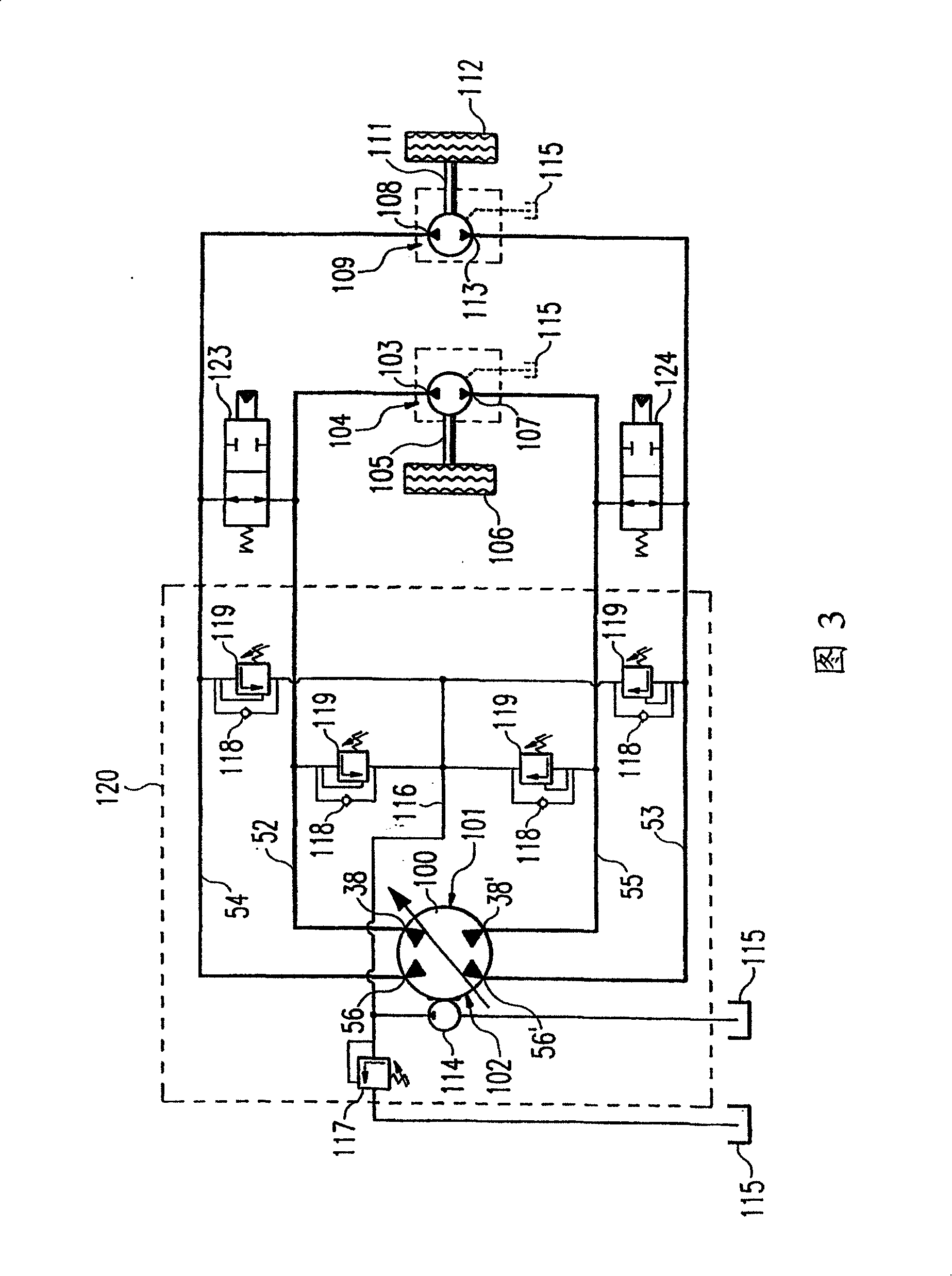

[0015] Referring now to FIGS. 1 and 2 , an exemplary embodiment of a hydraulic pump 100 according to the present invention with a hydraulic transmission system that distributes the amount of hydraulic fluid in the pump is illustrated.

[0016] The longitudinal section of the hydraulic pump 100 shown in FIG. 1 shows how the common transmission shaft 1 is mounted through a roller bearing 2 at one end of the pump housing 3 . The common transmission shaft 1 is additionally mounted in a slide bearing 4 arranged in a web 5 , which closes the opposite end of the pump housing 3 .

[0017] Formed in the connecting plate 5 is a hole 6 extending axially from the right through the connecting plate, in which on the one hand the plain bearing 4 is accommodated and on the other hand the common transmission shaft 1 passes through the hole 6 . On the side of the connecting plate 5 facing away from the pump housing 3 , the auxiliary pump 7 is inserted in a radial widening in the bore 6 . To dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com