Rebar cutting device with automatic measuring and marking functions

A cutting device, automatic measurement technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of troublesome operation, low degree of automation, trouble, etc., to achieve convenient identification and detection, improve work efficiency, high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

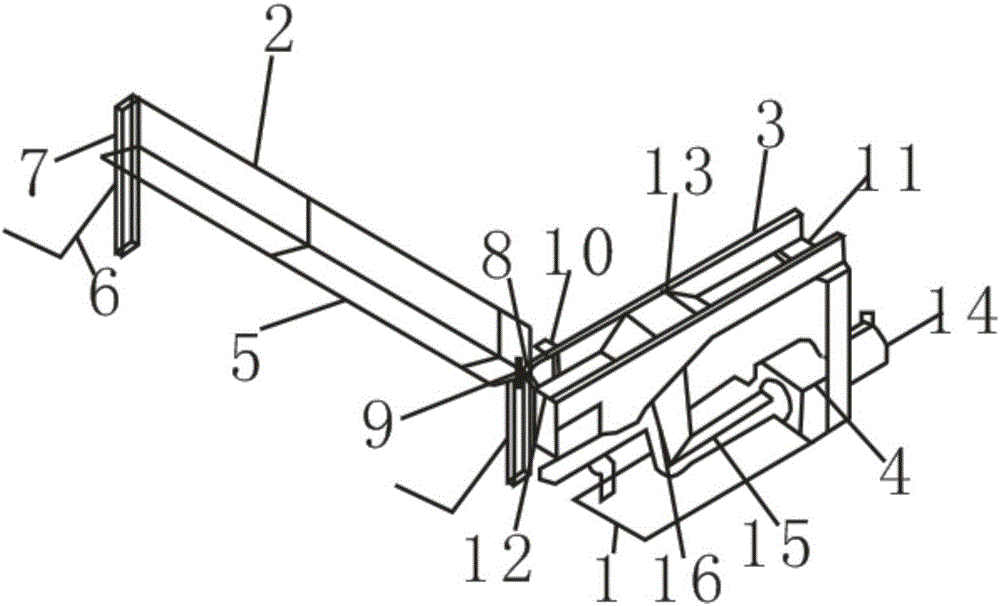

[0015] see figure 1 and figure 2 The present invention provides a technical solution: a steel bar cutting device for automatically measuring marks, including a cutting base 1, a feeding device 2, a cutting device 3 and a driving device 4, and the cutting device 3 and the driving device 4 are fixed on the cutting base 1 The upper surface of the upper surface can be more stable during cutting and driving, reducing vibration and improving stability, and the cutting device 3 is arranged above the driving device 4, which is convenient for the driving device 4 to provide power, and makes full use of the occupied space, reduces the volume of the device, and further The feeding device 2 includes a feed hopper 5 and a support column 7, the feed hopper 5 is made into a "V" shape, the feed hopper 5 is fixedly installed on the support column 7, and a steel bar hook 6 is installed on the feed hopper 7, Through the making effect of the support column 7, the feed hopper 5 and the steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com