A pivoting arm structure with wire harness passing through the middle

A technology of rotating arm and threading, which is applied in the direction of handrails, etc., which can solve the problems of easy damage of wire harness, unsightly appearance, inconvenient use of electronic screen, etc., and achieve the effect of satisfying use and avoiding poor aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

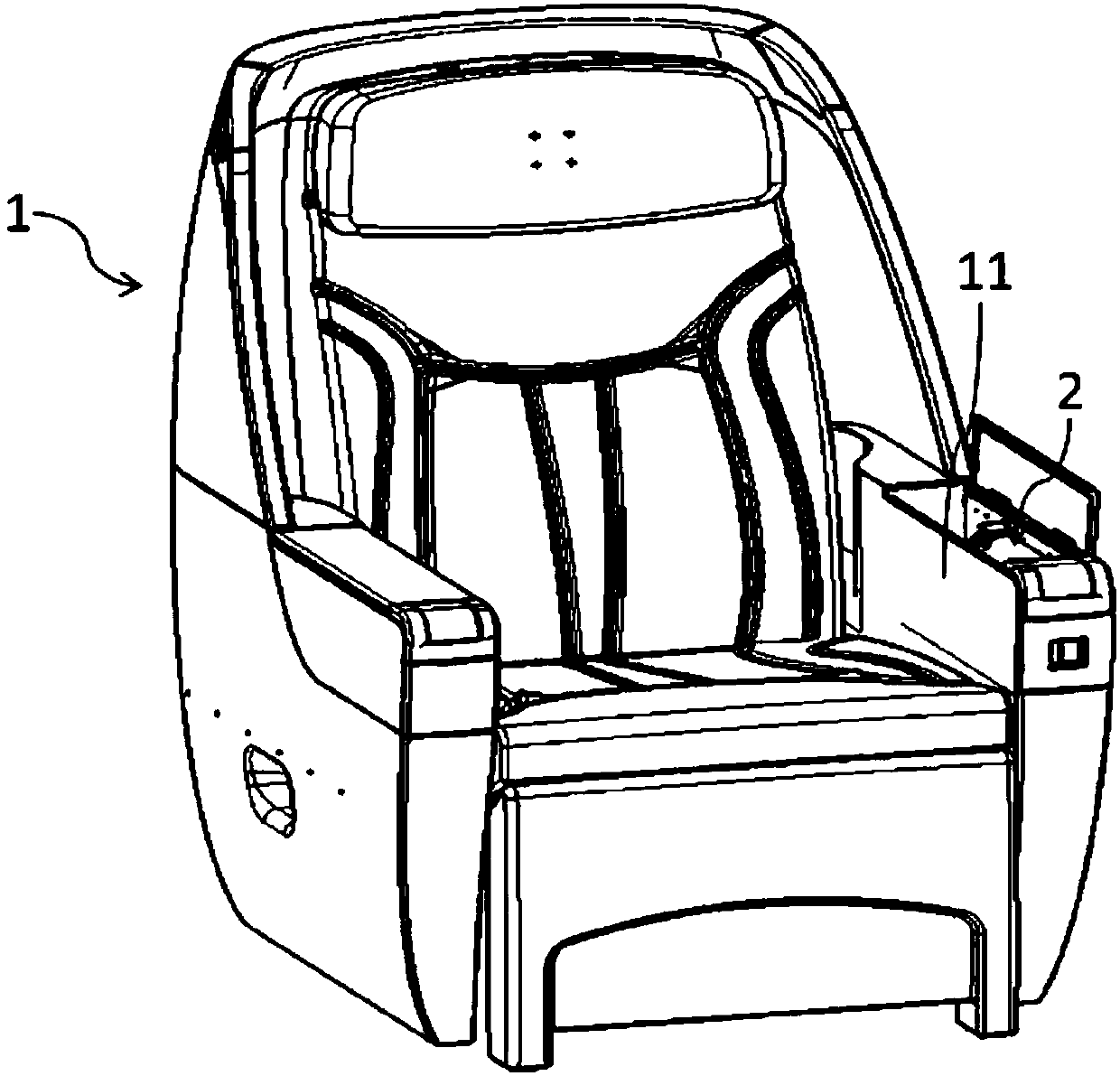

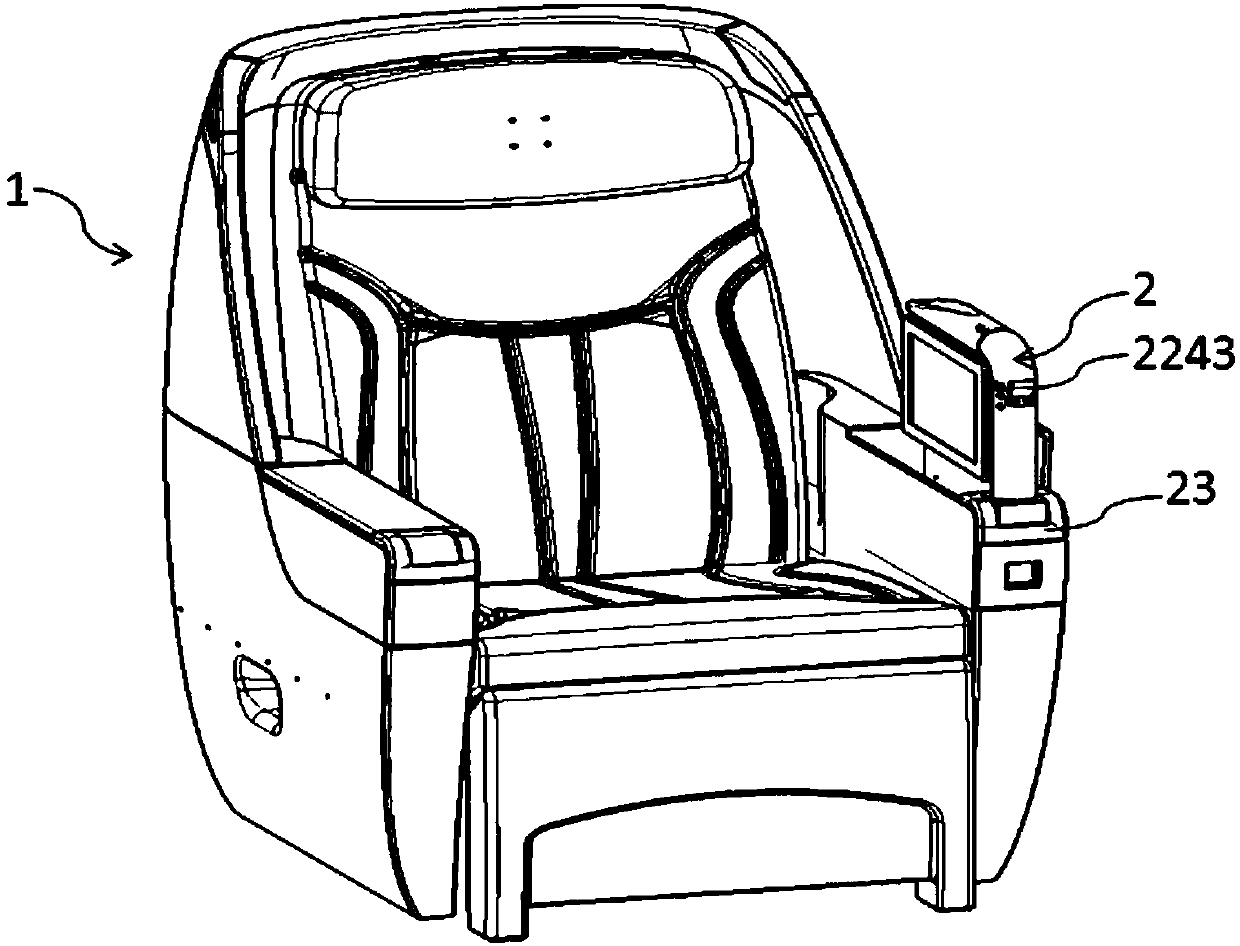

[0033] figure 1 Shown is a vehicle seat 1 in which a pivot arm structure 2 according to the invention is installed in the left armrest 11 .

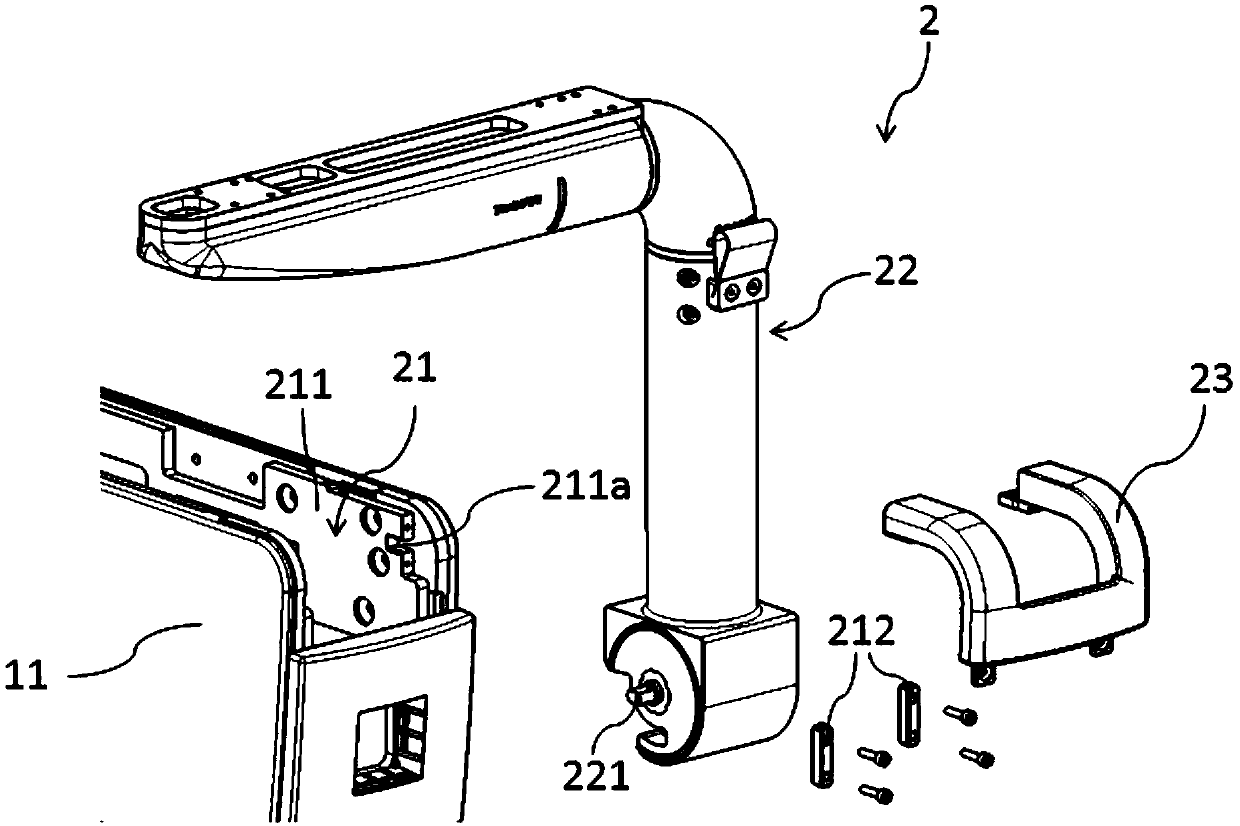

[0034] figure 2 yes figure 1 A partial schematic diagram of the left armrest 11 and the pivoting arm structure 2 of the present invention. Wherein, the left armrest 11 includes two opposite side plates, defining a space for accommodating the rotating arm structure 2 therebetween. The rotating arm structure 2 includes a fixing frame 21 , a rotating arm main body 22 and a decorative cover 23 . Wherein, the fixing frame 21 includes two opposite fixing plates 211 (only one side fixing plate is indicated in the figure), which are respectively fixed on the inner sides of the two side plates of the left armrest 11 . The front end of the side fixing plate 211 has a rectangular groove 211a. The fixing frame 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com