Aerial platform vehicle work platform leveling device with platform tiling prevention function

A technology for aerial work vehicles and working platforms, which is applied in the direction of lifting devices, etc., can solve the problems of inconvenient installation and adjustment, mechanism damage, mechanism failure, etc., and achieves the effects of simple structure, overturning prevention, and stable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

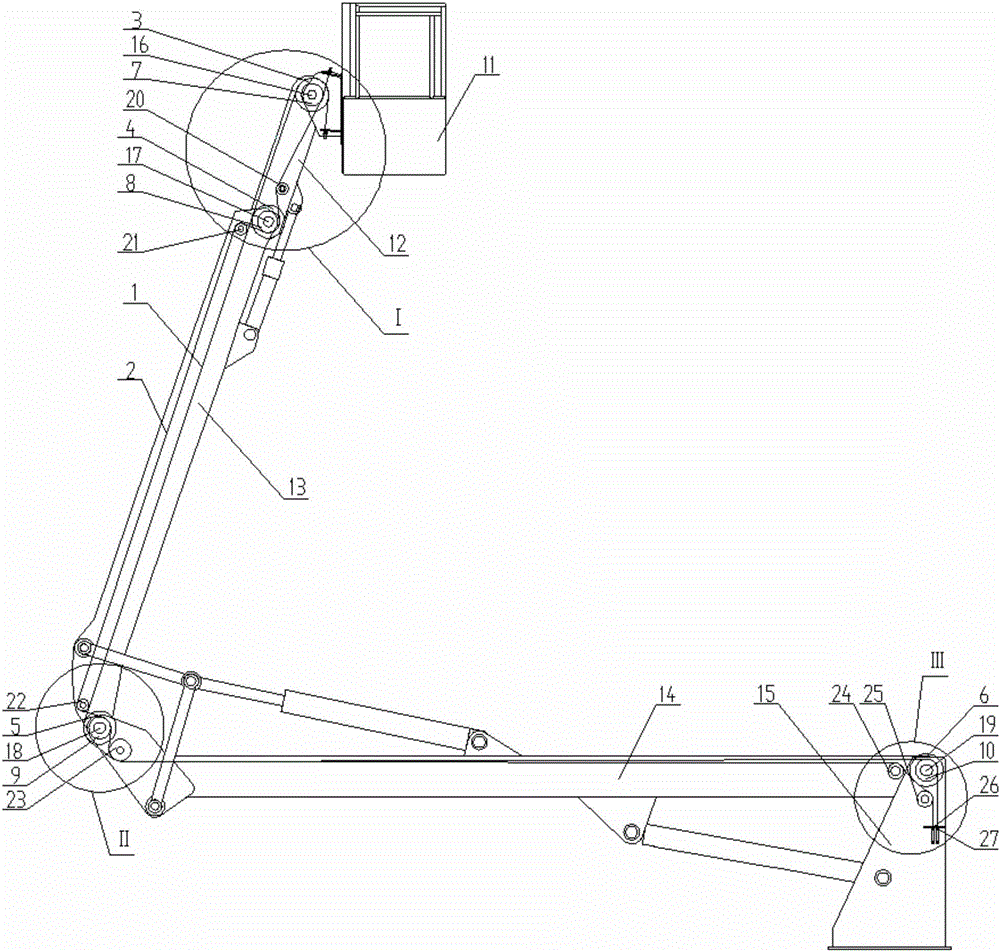

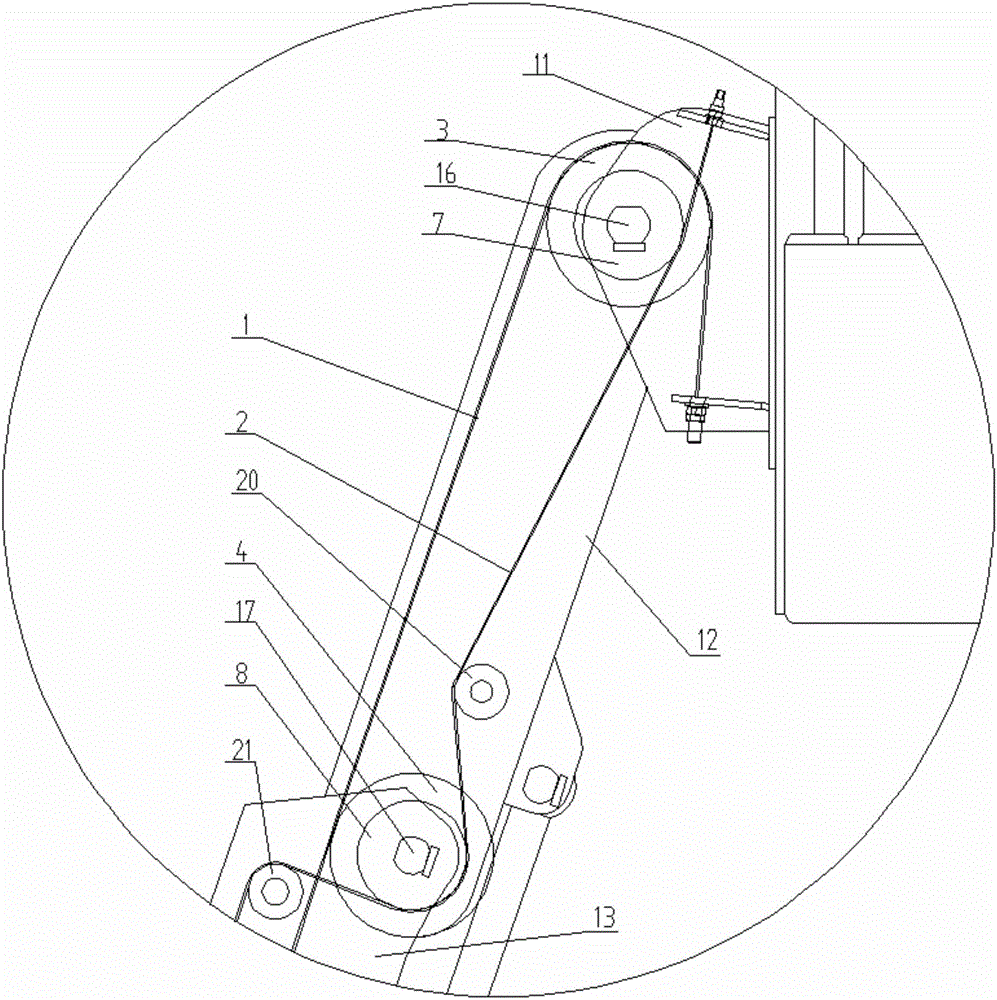

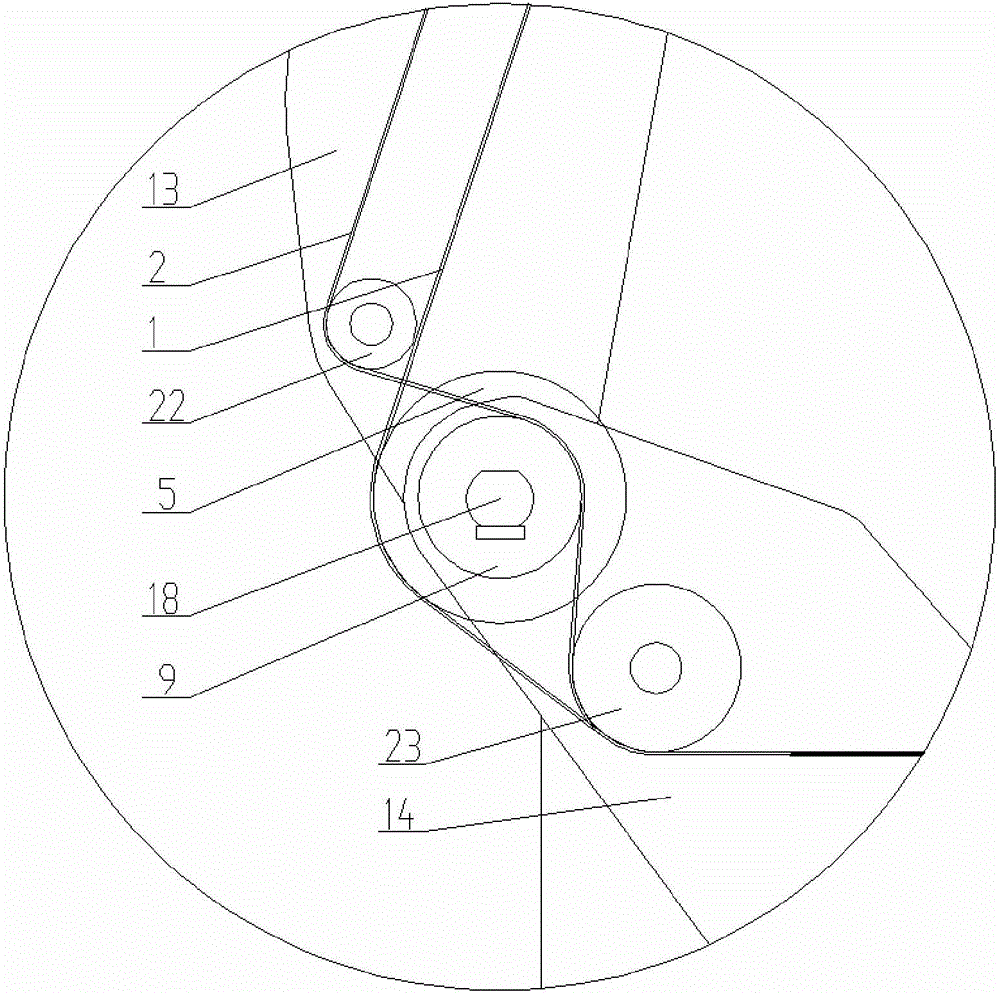

[0030] Embodiment 1, the working platform leveling device of the aerial work vehicle with anti-platform tipping function, such as figure 1 Shown is a schematic structural diagram of an embodiment of the present invention. This embodiment is provided with forward wire rope 1, reverse wire rope 2, forward leveling wheel I3, forward leveling wheel II4, forward leveling wheel III5, forward leveling wheel IV6, reverse leveling wheel I7, Reverse Leveling Wheel Ⅱ8, Reverse Leveling Wheel Ⅲ9, Reverse Leveling Wheel Ⅳ10, Working Platform 11, Arm Ⅰ12, Arm Ⅱ13, Arm Ⅲ14, Turntable 15, Axis Ⅰ16, Axis Ⅱ17, Axis Ⅲ18, Axis Ⅳ19, Transition Wheel Ⅰ20, transition wheel Ⅱ21, transition wheel Ⅲ22, transition wheel Ⅳ23, transition wheel Ⅴ24, transition wheel Ⅵ25, adjustment nut Ⅰ26, adjustment nut Ⅱ27; working platform 11, forward leveling wheel 3, reverse leveling wheel Ⅰ7, arm Ⅰ12 is articulated through shaft Ⅰ16, arm Ⅰ12, forward leveling wheel Ⅱ4, reverse leveling wheel Ⅱ8, arm Ⅱ13 is articula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com