Negative bending moment steel strand threading tool and its application method

A steel strand and negative bending moment technology, which is applied in the field of negative bending moment steel strand threading tools, can solve the problems that affect the life safety of the threading construction personnel, the hidden dangers of the threading construction, and the time-consuming and laborious construction of the threading construction. , to achieve safe and reliable construction process, safe and reliable beam-through construction operation, and avoid scratching and injury effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

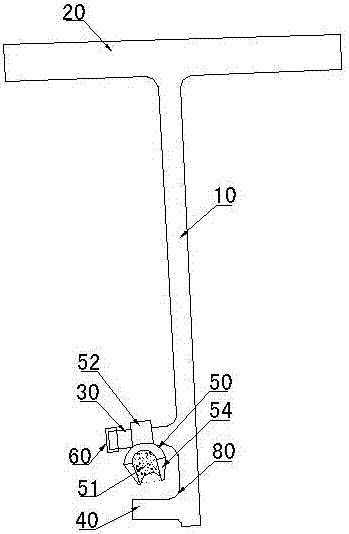

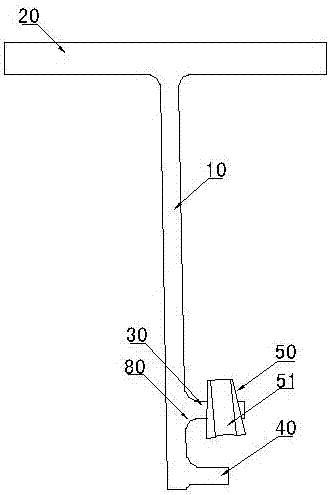

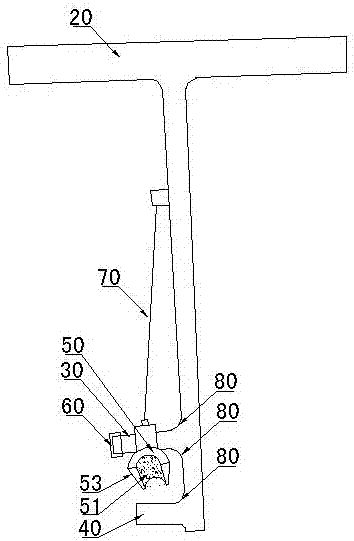

[0026] figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment, a negative bending moment steel strand threading tool includes a pull rod 10, a pull handle 20 is fixedly connected to the upper end of the pull rod 10, and the pull handle 20 is fixedly connected to the end of the pull rod 10 to form a T-shaped structure. At the lower end of the pull rod 10, two parallel inner and outer lateral card bodies are connected, and the positioning friction plate 50 that is connected to the inner lateral card body 30 on the side of the pull handle is movably rotated, and the positioning friction There is an arc groove 51 on the sheet, the axial arc surface of the arc groove 51 is perpendicular to the inner transverse card body 30, and the axial arc surface of the arc groove 51 is rotated on the inner transverse card body 30 toward the outside The axial arc surface of the transverse card body 40 is spatially inclined towards the outer transverse card body 40; the outer side...

Embodiment 2

[0028] image 3 In the shown embodiment, the positioning friction plate is provided with a drawstring structure that adjusts the rotation direction of the positioning friction plate on the connecting body that is movably connected with the inner lateral card body, and the other end of the pull rope 70 of the pull rope structure is connected to the upper end of the pull rod. . Others are identical with embodiment 1.

Embodiment 3

[0030] Another object of the present invention is to provide a method for using a negative moment steel strand threading tool, which includes the following steps:

[0031] A beam-through construction worker A uses both hands above the pier to directly penetrate the front end of the steel strand into the corrugated pipe B on the side where the beam-through construction worker A is directly facing the direction above the bridge pier;

[0032] Another beam-threading construction worker B holds the pull handle described in Embodiment 1 or Embodiment 2 with both hands, and clamps the inner and outer lateral clamps at the lower end of the pull rod to the steel strand to be threaded, and makes Embodiment 1 Or after one of the arc-shaped grooves of the positioning friction plate on the inner lateral card body described in Embodiment 2 is locked and positioned with the steel strand, pull the pull handle hard to make the steel strand penetrate further in the direction of the construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com