Cableless layering water injection method capable of achieving downhole flow, pressure and temperature monitoring

A layered water injection, cableless technology, applied in the directions of measurement, production of fluids, and earth-moving drilling, etc., can solve the problems of inability to realize two-way communication between the surface and underground, large diameter influence, etc., and achieve the effect of convenient and efficient deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, features and effects of the patent of the present invention, the following examples are given as examples, and detailed descriptions are as follows with accompanying drawings:

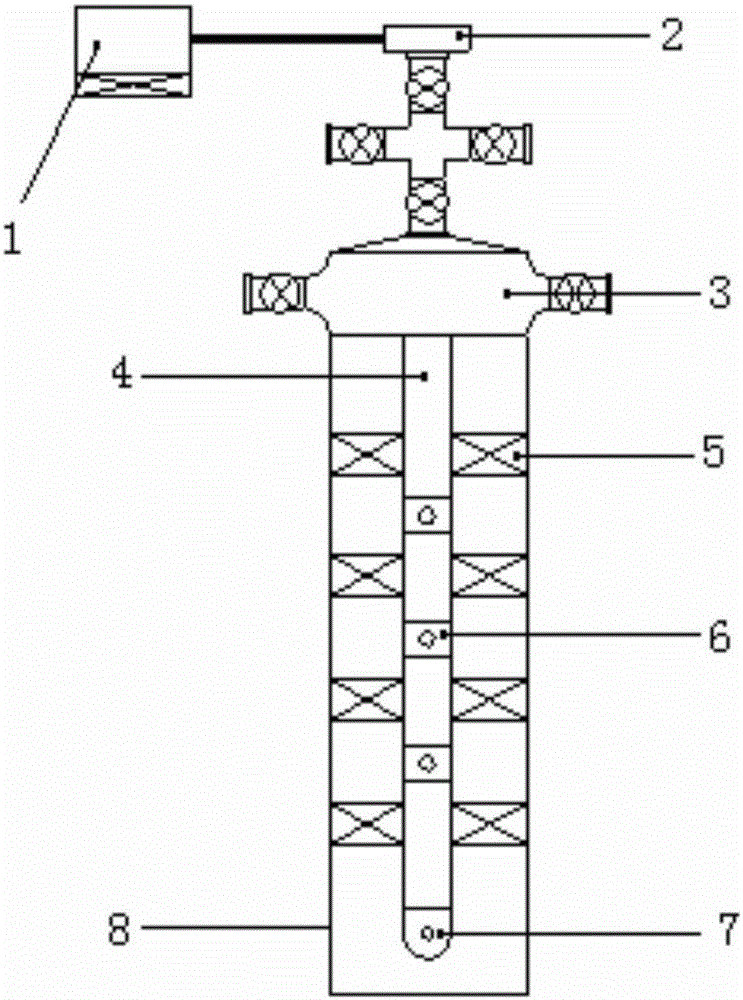

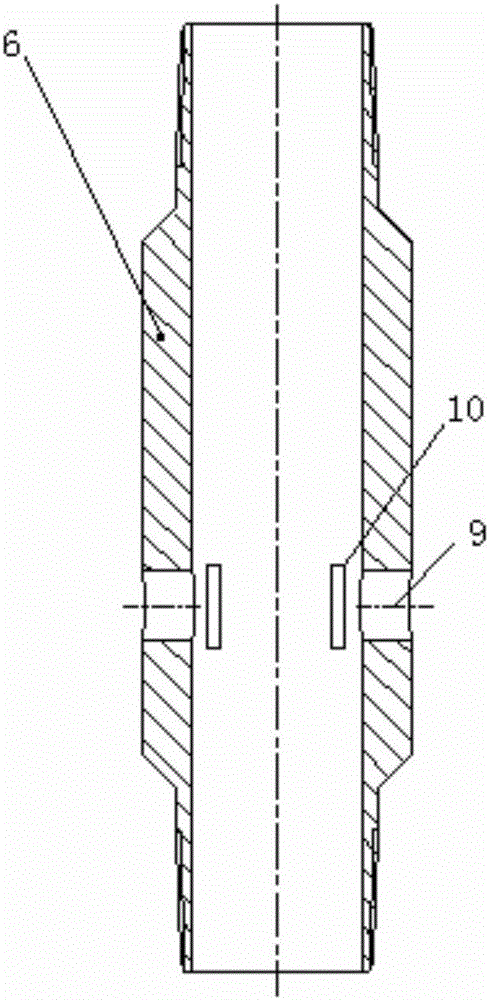

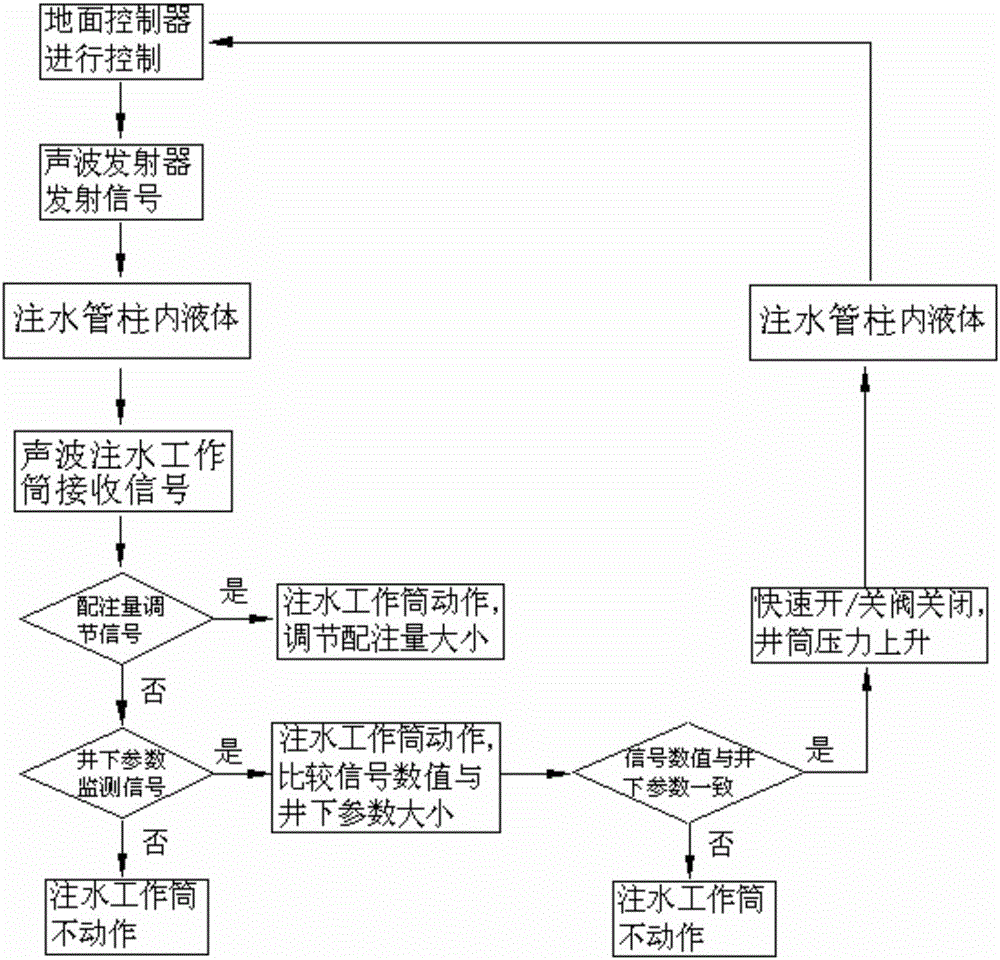

[0022] Such as figure 1 with figure 2 As shown, the water injection pipe string in the present invention includes a plug 7, a sonic water injection mandrel 6, a tubing and tubing stub 4, a wellhead device 3, etc., which are sequentially connected from bottom to top. It is a threaded connection buckle, which is used to connect with the tubing and tubing stub 4. A water nozzle 9 is provided along the circumference to inject water into the corresponding water injection layer. An electromagnetic quick opening / closing valve 10 is correspondingly provided in the water nozzle 9. A flow sensor, a temperature sensor and a pressure sensor (two channels, which can measure the pressure value before and after the water nozzle 9) are also installed in the sonic water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com