Four-way positioning rotary elastic locking handle device

A technology of positioning rotation and elastic lock, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems that personnel cannot smoothly complete equipment transfer tasks, large storage space, poor ergonomics, etc., and achieve good man-machine adaptability and save storage The effect of space and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

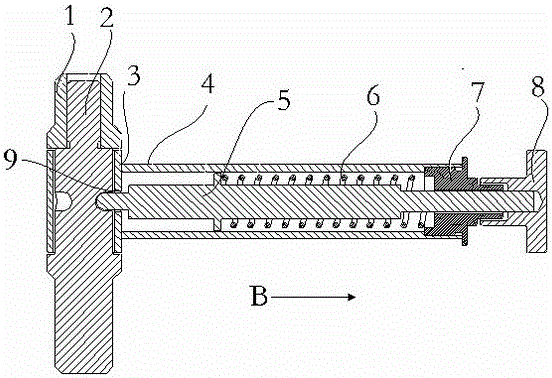

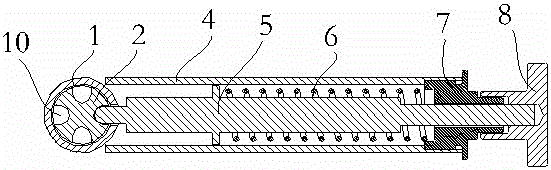

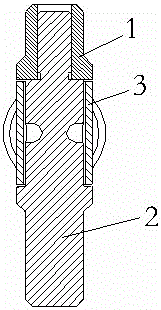

[0026] like Figure 1-16 , the utility model works and implements in this way, a four-way positioning rotary elastic locking handle device, the shaft tube 3 and the sheath 4 are welded as one, and the middle part of the shaft tube 3 has a shaft tube through hole 9, the shaft The tube 3 is installed on the main shaft 2, limited by the shaft sleeve 1, and can rotate along the main shaft 2. The main shaft 2 has a positioning hole every 90°, and the standard cylindrical helical compression spring 6 and the ejector rod 5 are installed in the sheath 4. The retaining ring 7 is installed on the top of the sheath 4, cooperates with the ejector rod 5, encapsulates the standard cylindrical helical compression spring 6 inside the sheath 4 and makes the ejector rod 5 in the state of bearing the elastic force of the standard cylindrical helical compression spring 6, under the action of the spring force Next, the thimble at the front end of the ejector rod 5 passes through the through hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com