A three-wheel ratooned rice harvester with variable front wheel pitch and its control method

A technology of regenerated rice and variable wheels, which is applied in the fields of harvesters, agricultural machinery and implements, agriculture, etc., can solve problems such as reducing the yield of regenerated rice, and achieve the effects of automatic control, simple operation and increased yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

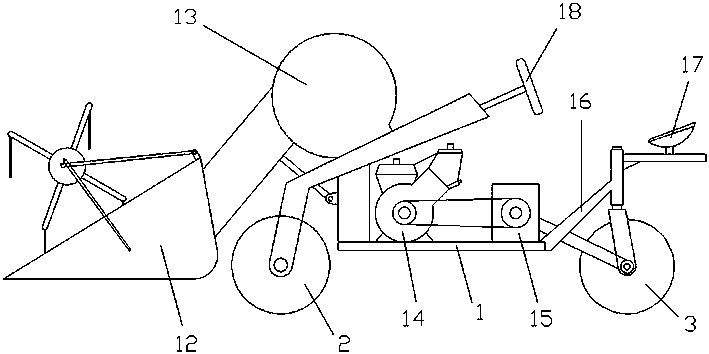

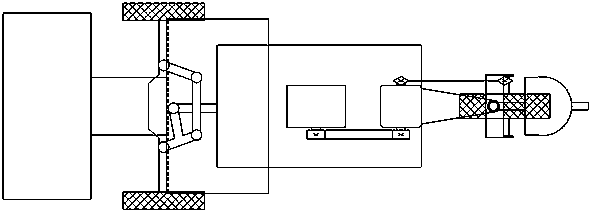

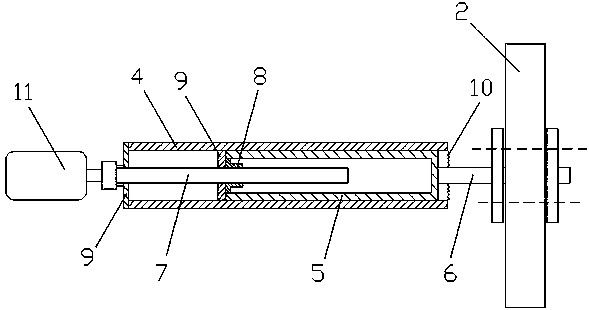

[0016] Such as Figure 1~3 As shown, a three-wheel ratooned rice harvester with variable front wheel spacing includes a chassis 1, a pair of front wheels 2 are provided at the front end of the chassis 1, and a rear wheel 3 is provided at the rear end of the chassis 1; Each side is respectively provided with a telescopic mechanism to control the lateral movement of the front wheel on the corresponding side. The telescopic mechanism includes an outer sleeve 4 installed on the bottom of the chassis 1 and an inner sleeve sleeved in the outer sleeve 4 and slidingly matched with the outer sleeve 4. 5. The outer end of the inner sleeve 5 is fixedly connected with a push rod 6 that passes through the outer sleeve 4 and connects with the front wheel 2 on the corresponding side. The screw mandrel 7, the inner sleeve 5 is provided with the screw mandrel nut 8 matched with the screw mandrel 7 so that when the screw mandrel 7 rotates, the front wheel moves laterally through the inner sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com