A drainage board insertion mechanism

A drainage board and insertion technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of poor safety reliability and versatility, limited application range, unstable insertion quality, etc., to achieve safety and reliability Good compatibility and versatility, wide application range, and stable insertion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

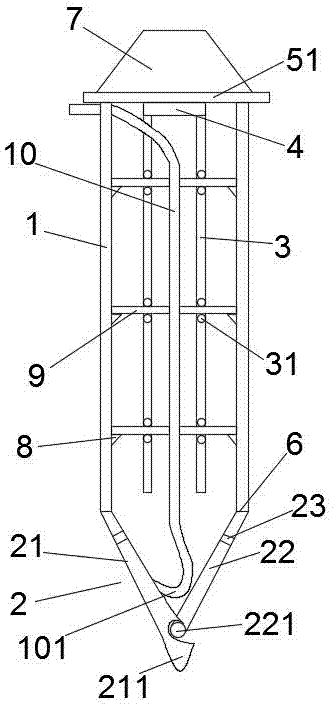

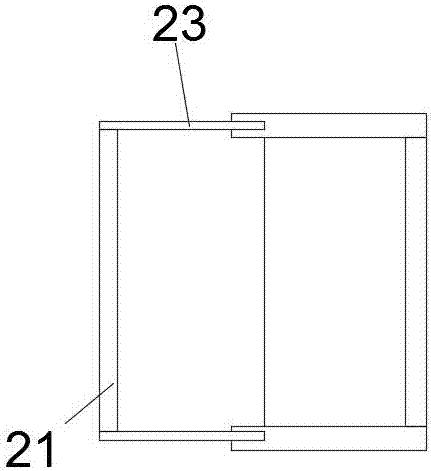

[0028] A drainage plate insertion mechanism, comprising a sleeved pile tube 1 with a guide plate cavity inside, an inverted cone pile head 2 located at the bottom of the sleeved pile tube, and two columns are symmetrically hinged on the cavity wall of the guide plate for pressing on The pressure plate 9 on the drainage board 10 is connected with the pressure plate to make the pressure plate rotate around the hinge point; the inverted cone pile head includes two partially overlapping pile head plates with closed or open lower ends.

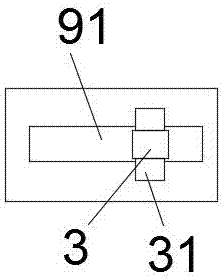

[0029] The elastic assembly includes two connecting rods 3 that pass through two rows of pressing plates, and a synchronizing connecting plate 4 that is detachably connected to the tops of the two connecting rods.

[0030] A bearing plate 51 located above the synchronous connecting plate is erected on the top of the sleeved pile pipe, and the upper surface of the synchronizing connecting plate abuts against the bottom surface of the bearing plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com