Ditching machine for seeder

A trench opener and seeder technology, which is used in fertilizer and seeding equipment, excavation/covering of trenches, applications, etc., can solve the problems of straw and weed congestion, inability to sow, and difficulty in guaranteeing the depth of trenching, and achieve higher The effect of adaptability, improving utilization rate, and meeting the requirements of fertilization and sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

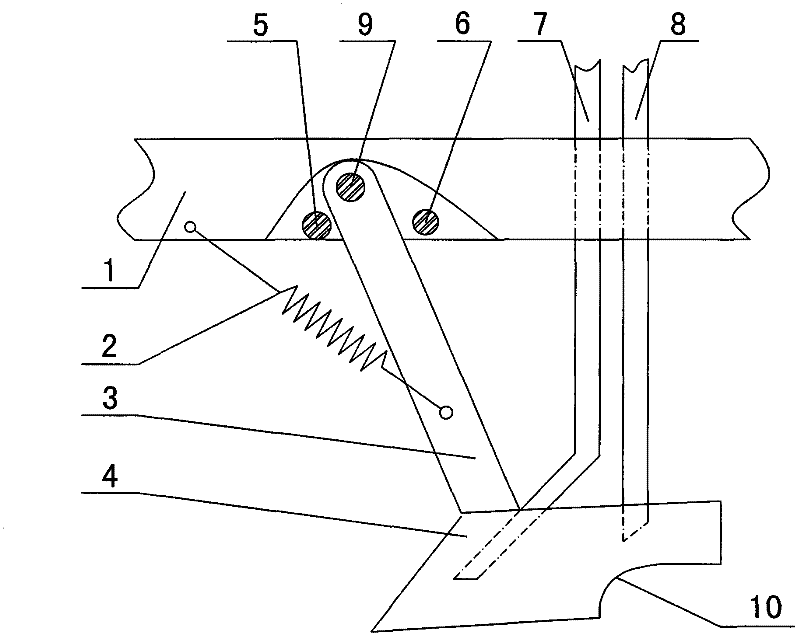

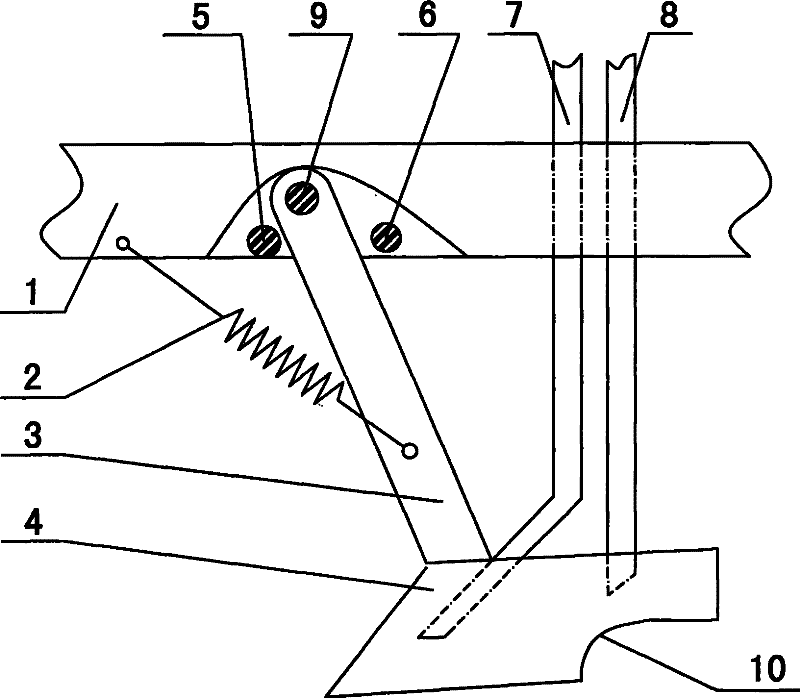

[0014] The upper end of the handle column 3 is hinged on the seeder beam 1 by a cylindrical pin 9, and the lower end is fixedly connected with the opener 4. The seeder beam 1 is provided with a front limit block 5 and a rear limit block on both sides of the handle column 3. Block 6, so that when the handle column 3 swings to the front limit block 5, the tip of the opener 4 is just below the cylindrical pin 9, and when the handle column 3 swings from the front limit block 5 to the rear limit block 6 1. The swing angle of the handle column 3 is 8-10°. The upper end of the adjustment spring 2 is fixed on the crossbeam 1 of the planter and is located at the front end of the front limit block 5, and the other end is hinged on the lower half of the handle column 3 for ditching. The back bottom of device 4 is provided with wet soil backflow otch 10, and the lower end of manure guide pipe 7, seed guide pipe 8 probes in the ditch opener 4, and manure guide pipe 7 is positioned at the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com