Leak detection device for air chamber port of intercooler

A gas chamber and leak detection technology, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement. Safety, good leak detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

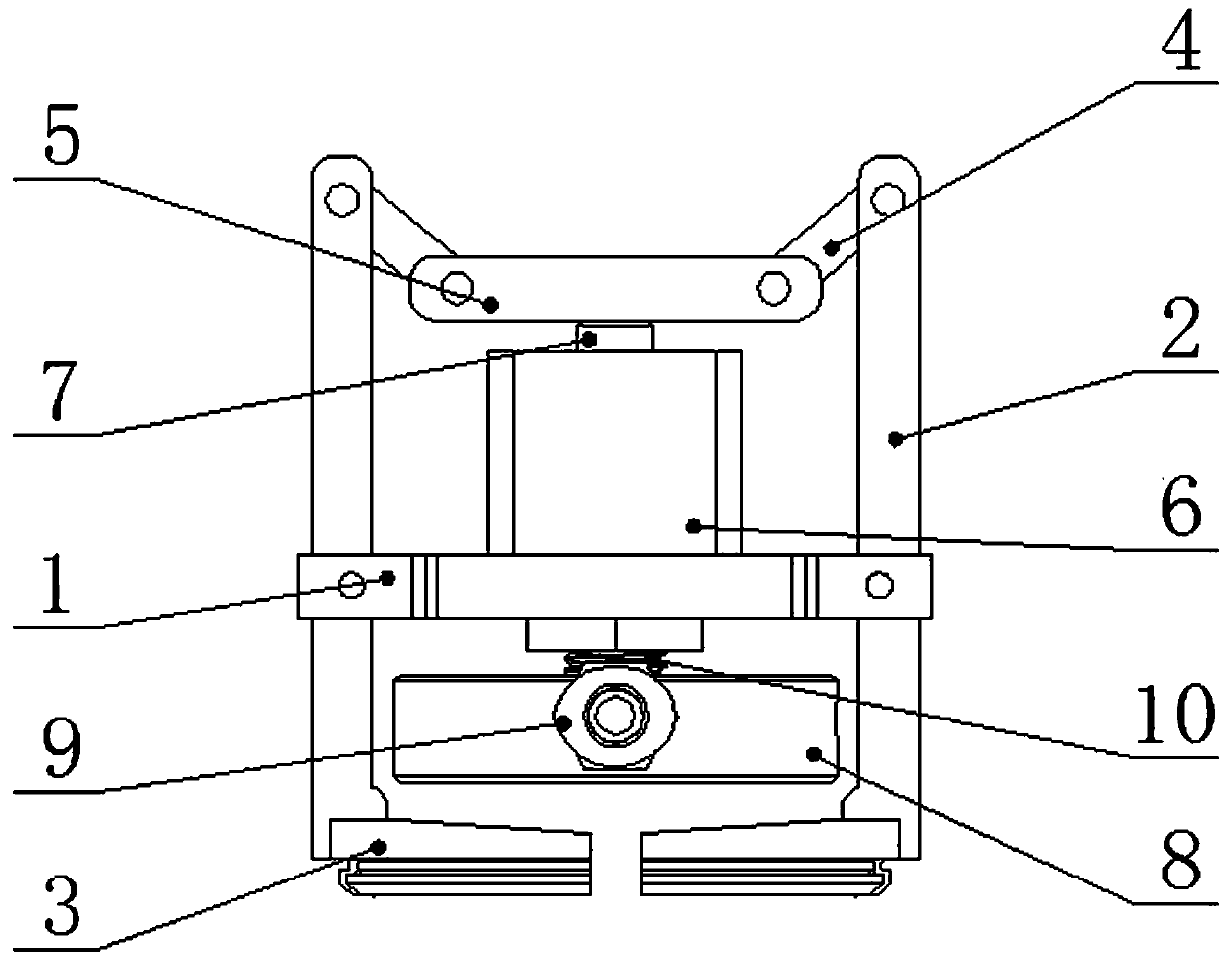

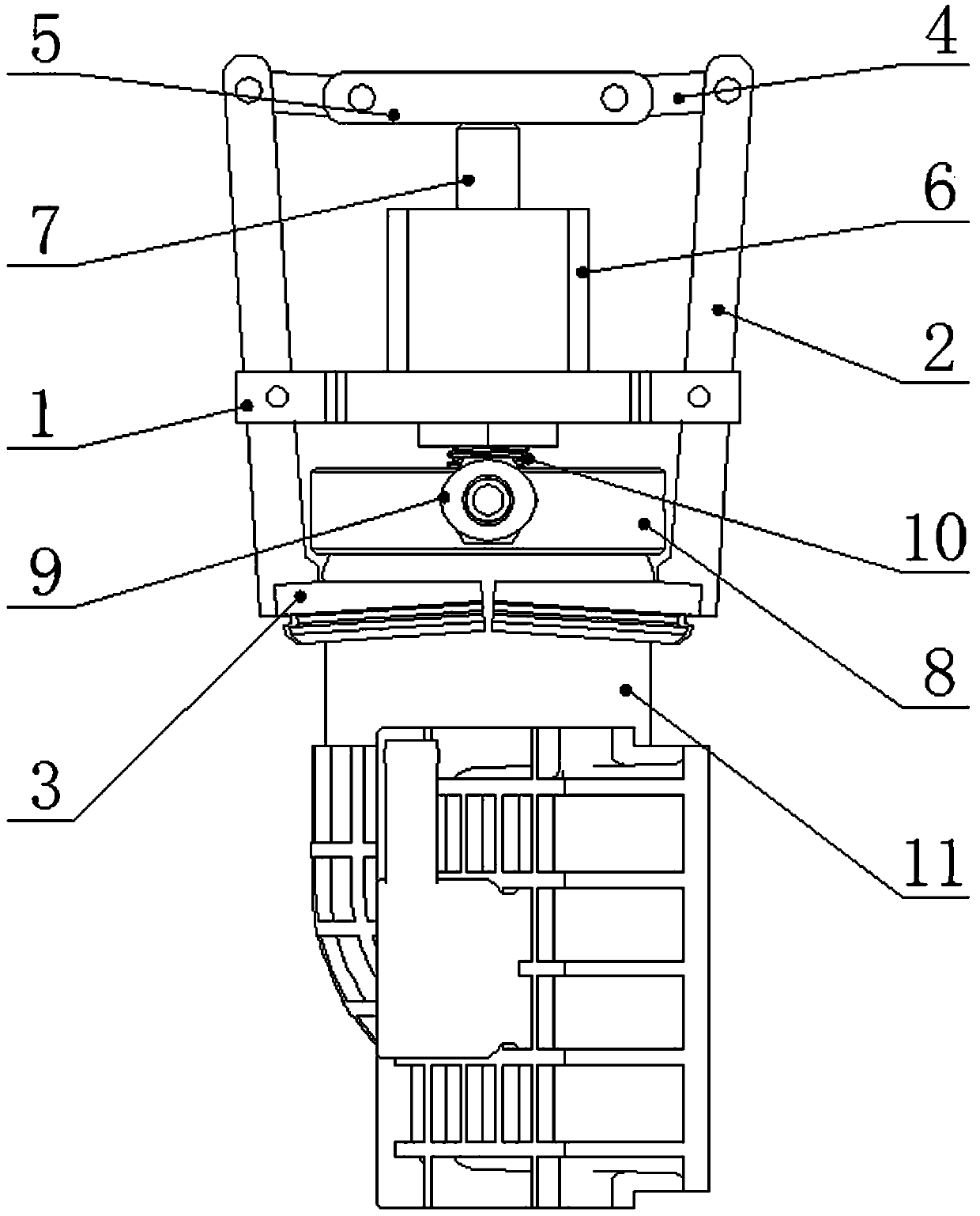

[0016] Such as Figure 1 to Figure 2 The shown leak detection device for the air chamber port of an intercooler includes a support plate 1, swing arms 2 are hinged on both sides of the support plate 1, claws 3 are provided at the lower ends of the two swing arms 2, and claws 3 The arc-shaped structure that matches the outer wall of the air intake pipe 11 of the radiator air chamber makes the claw 3 and the outer wall of the air intake pipe 11 fit and clamp better, ensuring that the outer wall of the air intake pipe 11 can be evenly stressed. The clamping effect of the claw 3 is improved.

[0017] The upper ends of the two swing arms 2 are hinged with a connecting rod 4, and a cross bar 5 is hinged between the two connecting rods 4. The sum of the lengths of the cross rod 5 and the two connecting rods 4 is greater than the distance between the upper ends of the two swing arms 2 The gap effectively improves the sensitivity of the leak detection device to feedback the pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com