Resin LED luminous character and manufacturing method thereof

A technology of luminous characters and LED light modules, which is applied in the field of advertising signs, can solve the problems that the luminous characters on acrylic panels cannot achieve this effect, and achieve good publicity effects and uniform luminous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

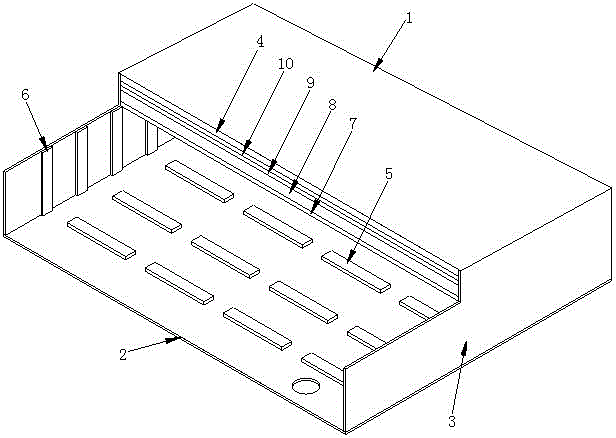

[0023] Such as figure 1 Shown is a resin LED light-emitting character of this embodiment, including a bottom plate 2 forming a character case 1, a side edge 3 and a cover plate 4, an LED lamp module 5 is arranged on the bottom plate 2, and an LED lamp module 5 is arranged on the side edge 3. A number of positioning pillars 6 are vertically arranged, and a transparent bearing plate 7 is arranged under the cover plate 4. The bearing plate 7 is supported by the positioning pillars 6, and a light guide layer 8, a color layer 9 and a protective layer are sequentially arranged on the bearing plate 7 from bottom to top. Layer 10, wherein the light guide layer 8 is an epoxy resin layer with light guide white, the color layer 9 is an epoxy resin layer with black particles, and the protective layer 10 is a transparent epoxy resin layer. Light guide white is a white high-transmittance color paste that allows the light to radiate evenly.

[0024] The black particles are black color paste...

Embodiment 2

[0027] A preparation method of resin LED luminous characters, comprising the following steps:

[0028] (1) Metal welding forms the bottom plate, side edge and cover plate of the letter case, the cover plate is polished and painted black, and the thickness of the letter case is 40-60mm;

[0029] (2) After the word shell is formed, install the LED light module on the bottom plate, the light is white, the brightness of a single light reaches 20 lumens, and the color temperature is 15000-18000;

[0030] (3) A number of positioning pillars are vertically arranged on the side edge below 12mm under the cover plate;

[0031] (4) Put a 3mm thick bearing plate on the positioning pillar, and glue the connection between the bearing plate and the side edge with transparent glass glue to prevent resin leakage;

[0032] (5) First pour epoxy resin with light guide white on the carrier plate, let it level off naturally, and completely cure to form a light guide layer;

[0033] (6) Pour epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com