Chip resistor and method for manufacturing same

一种贴片电阻、制造方法的技术,应用在电阻制造、电阻器、电阻器零部件等方向,能够解决导通不良、断线等问题,达到高精度电阻值调整的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

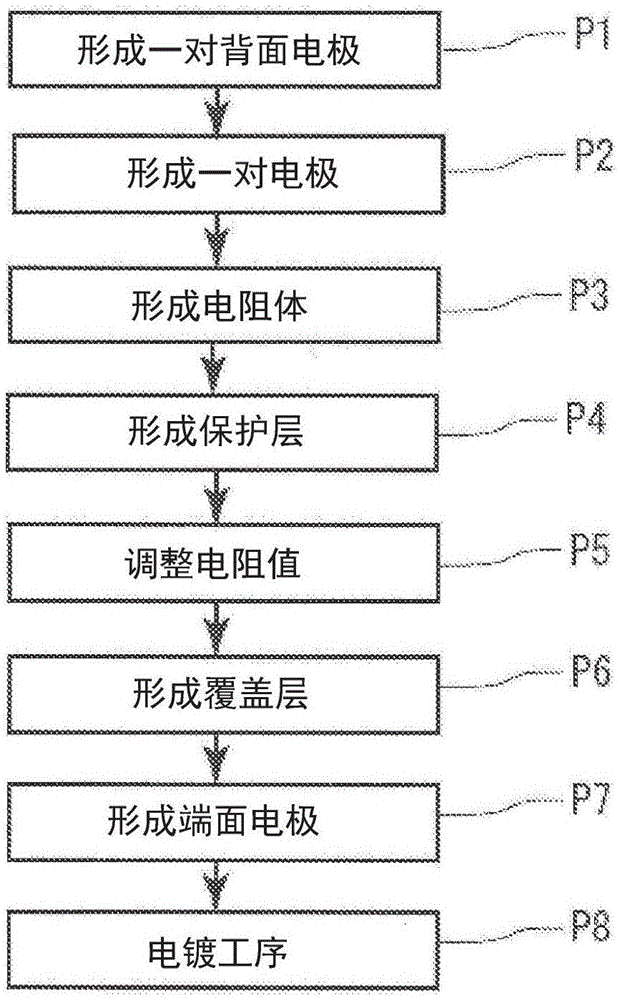

[0028] Hereinafter, the chip resistor and its manufacturing method according to the embodiment of the present invention will be described with reference to the drawings.

[0029] (Structure of the chip resistor described in the embodiment of the present invention)

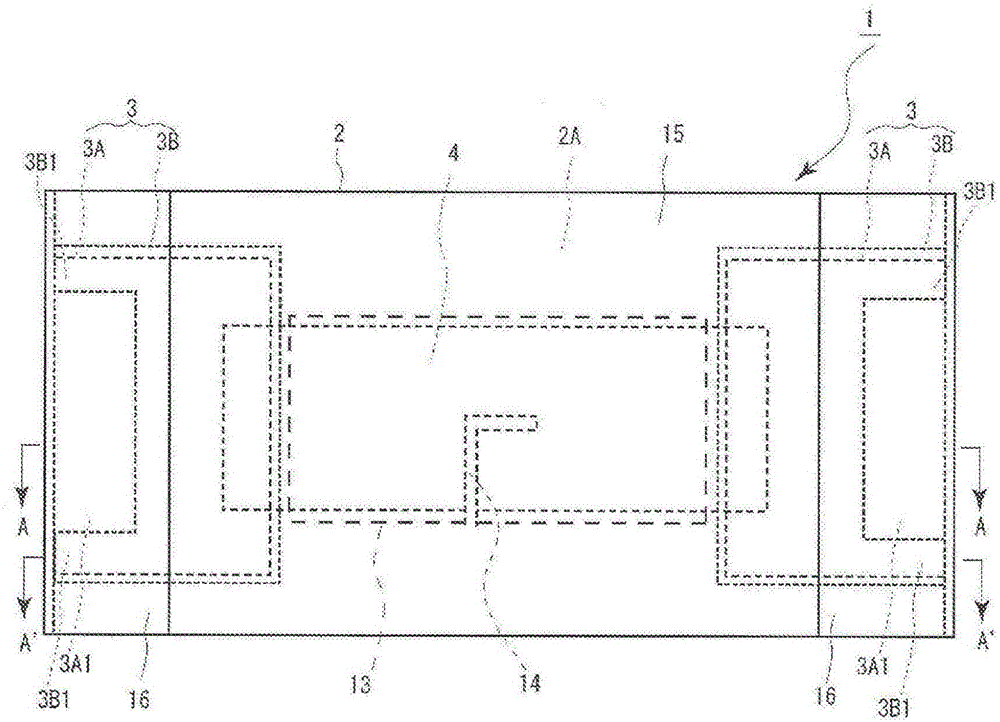

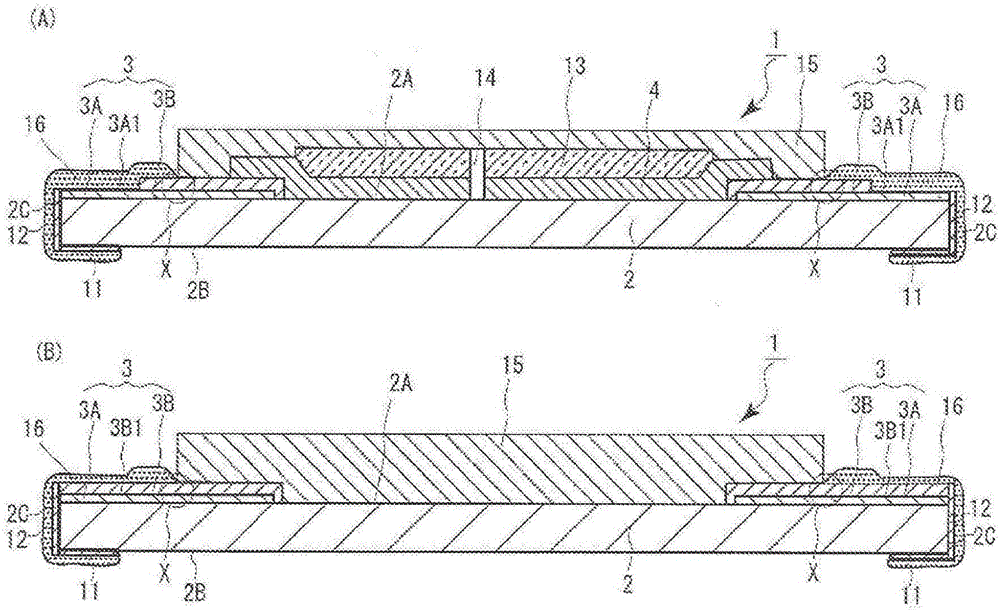

[0030] figure 1 It is a plan view of the chip resistor according to the embodiment of the present invention. figure 2 (a) is figure 1 A-A sectional view of, figure 2 (b) is figure 1 A'-A' sectional view. The chip resistor 1 has: an insulating substrate 2; a pair of electrodes 3, 3 formed on an upper surface 2A of the insulating substrate 2; 3 and 3 are formed so that both sides are in contact with ruthenium oxide as the main component; and an insulating film (covering layer 15 described later) that covers the resistor 4 and covers a part of the pair of electrodes 3 and 3 .

[0031] The pair of electrodes 3, 3 each have: an auxiliary electrode layer 3A having a rectangular planar shape; and a main electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com