Center rest of horizontal lathe

A horizontal lathe and center frame technology, which is applied in the field of processing devices, can solve the problems of bulkiness and easy breakage, and achieve the effects of convenient use, increased service life, and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

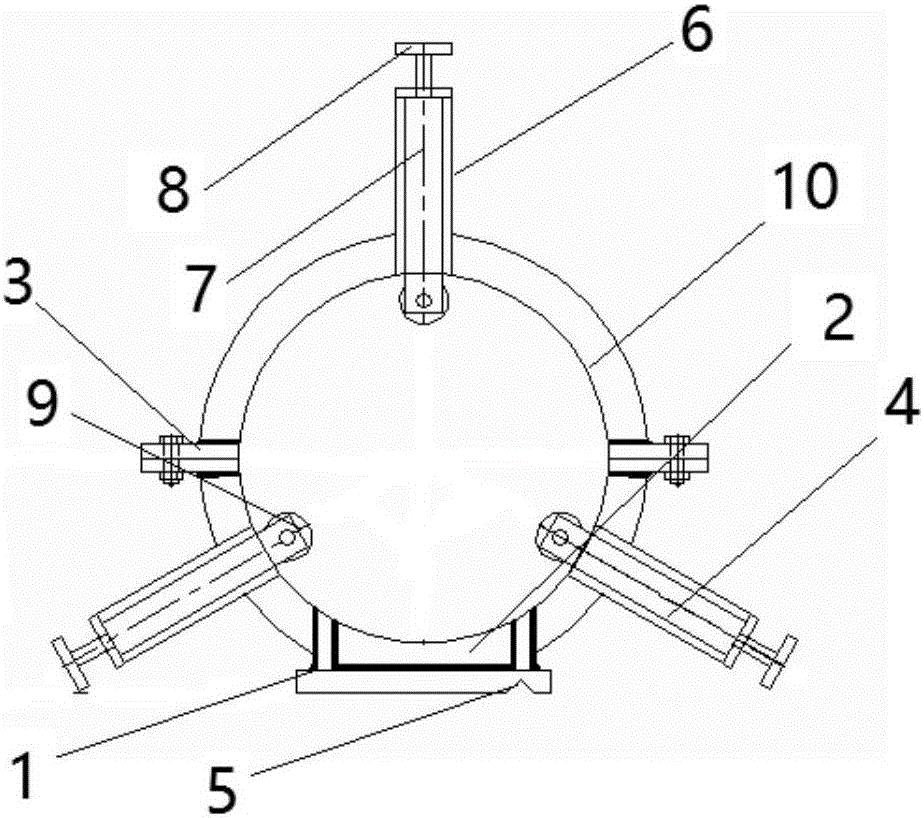

[0012] Horizontal lathe center frame, which includes a base, the base is provided with an inner ring, the inner ring is provided with an outer ring, the connection between the inner ring and the outer ring is provided with a groove, the There are feeding devices on the inner and outer rings.

[0013] Preferably, the base is provided with a chute matched with the lathe, and the chute is used to be fixed on the guide rail of the lathe.

[0014] Preferably, the feeding device includes an outer transmission sleeve and an inner transmission sleeve, the inner transmission sleeve is provided with a manually rotating screw, and one end of the inner transmission shaft is provided with a roller.

[0015] Preferably, the mutual angle between the feeding devices is 120°.

[0016] The outer ring and the inner ring are connected by fixing bolts.

[0017] When processing slender shafts and cylindrical workpieces, the workpiece is fixed by manually rotating the screw feed device. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com