Field litter layer thickness measuring device and method

A measuring device and litter technology, which is applied in the field of field litter layer thickness measurement devices, can solve the problems of large errors in field litter layer thickness measurement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

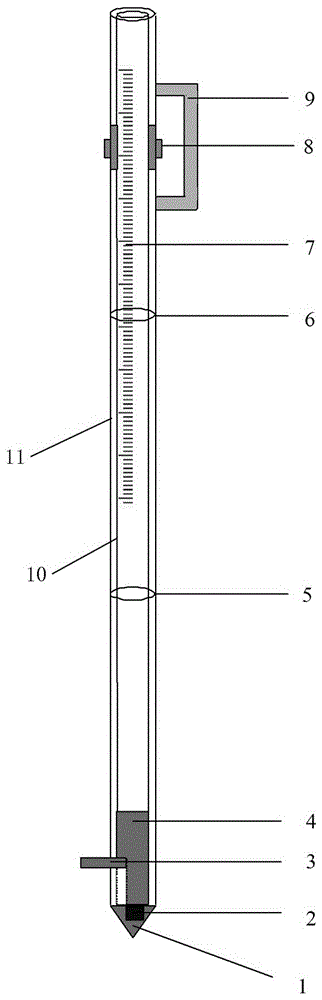

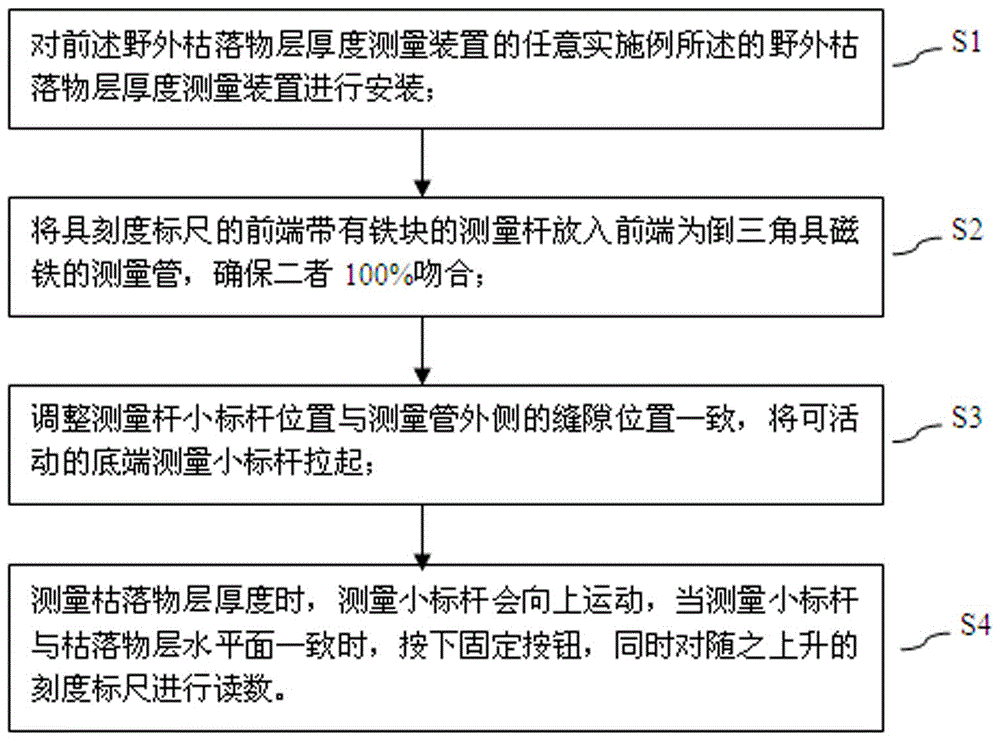

[0025] Such as figure 1 Shown, the litter layer thickness measuring device in the field comprises measuring rod 10 and measuring tube 11, and the top of the side wall of measuring rod is provided with tool scale scale 7, and the zero scale of scale is at the top, and is convenient for reading when measuring in the field; measuring rod The lower end of the bottom is provided with a benchmark 3, and the benchmark is rotated and set on the body of the measuring rod. The benchmark can be rotated by 90°, the measuring tube is set on the outside of the measuring rod, the side wall of the measuring tube is provided with a slot, and the benchmark is slidingly arranged in the slot; The bottom end of the measuring tube is the bottom end 1 of an inverted triangle tip, and a magnet 2 is embedded in the bottom end of the tip; an iron block 4 is arranged at the bottom end of the measuring rod, and the iron block matches the magnet at the bottom end of the measuring tube. The top of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com