Low error-sensitivity multi-target light source-mask optimization method based on vector imaging model

An imaging model and sensitivity technology, applied in optics, optomechanical equipment, microlithography exposure equipment, etc., can solve the problem of random errors that cannot be compensated for other wave aberrations, imaging light wave intensity or phase changes, affecting imaging resolution and preservation. Fidelity and other issues, to achieve good lithography performance, reduce the impact of lithography imaging, and achieve the effect of high graphic fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] Now assume that the random error in the lithography system is only the eighth Zernike polynomial z 8 The wave aberration represented by z 8 The coefficient c of the term 8 can represent the error of the system.

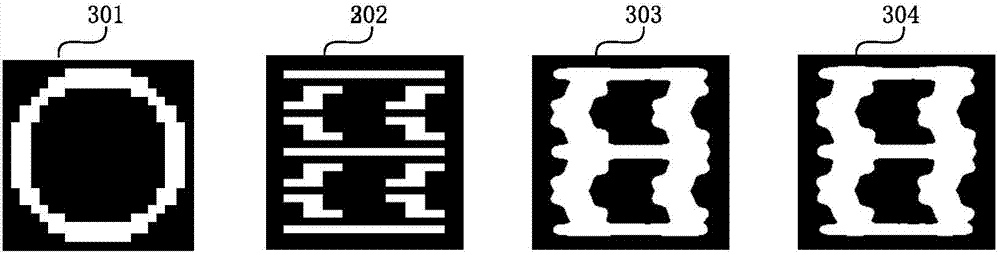

[0097] Such as image 3 Shown is a schematic of the initial light source, the initial mask and its corresponding imaging in the photoresist. exist image 3 Among them, 301 is the pattern of the preliminary test light source, white represents the luminous part, and black represents the non-luminous part. 302 is the initial test mask pattern, which is also the target pattern, white represents the light-transmitting area, black represents the light-blocking area, and its characteristic size is 45nm. in c 8 In the case of = 0, 303 is after adopting 301 as the light source and 302 as the mask, imaging in the photoresist of the photolithography system, and its graphic error is 7224 (the imaging fidelity function F is defined here as the value of the graphic err...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com