Method for making array micro-table-board of idium-gallium-arsenium coke plane detector

A focal plane detector, indium gallium arsenic technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve material lattice damage, poor passivation effect and anti-reflection effect, device performance degradation, etc. problem, to achieve the effect of reducing side damage, improving long-term stability and reliability, and improving graphic fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the concrete implementation method of the present invention is described in further detail:

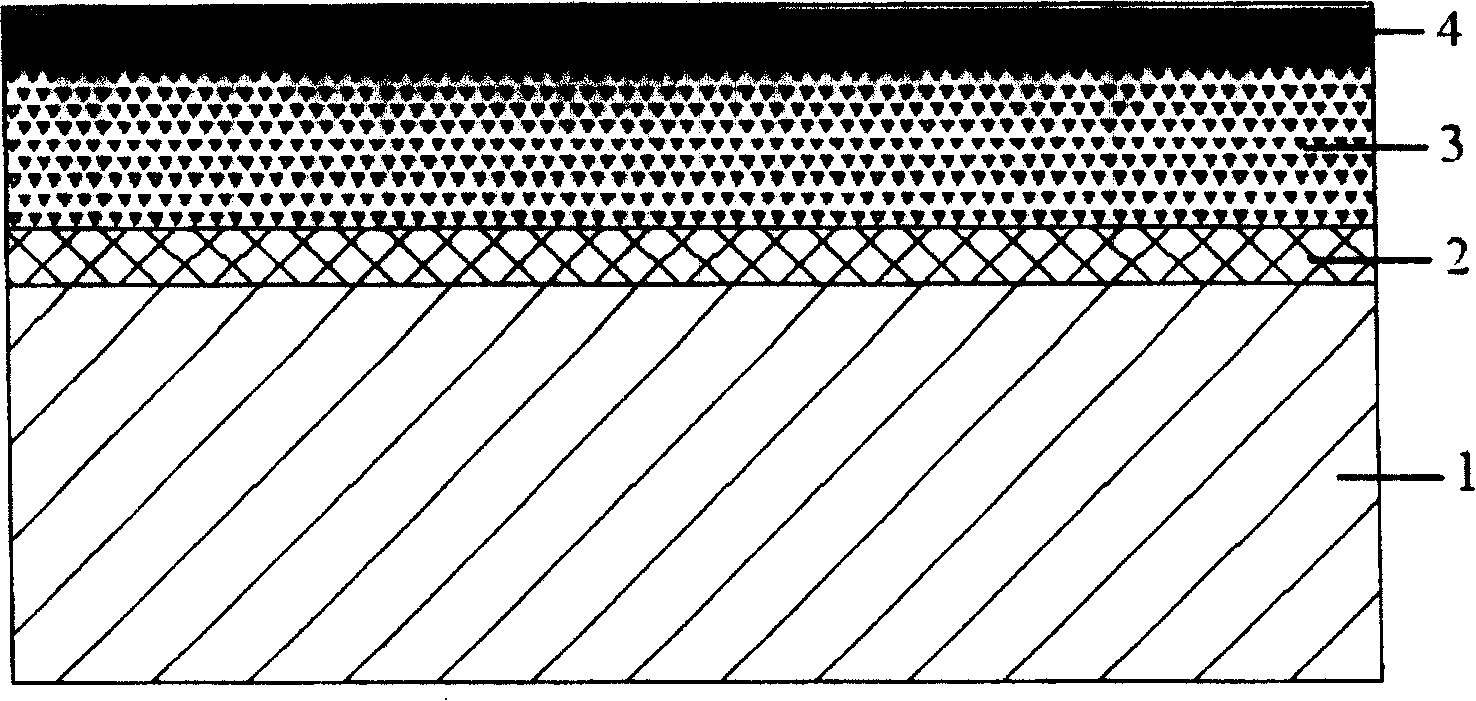

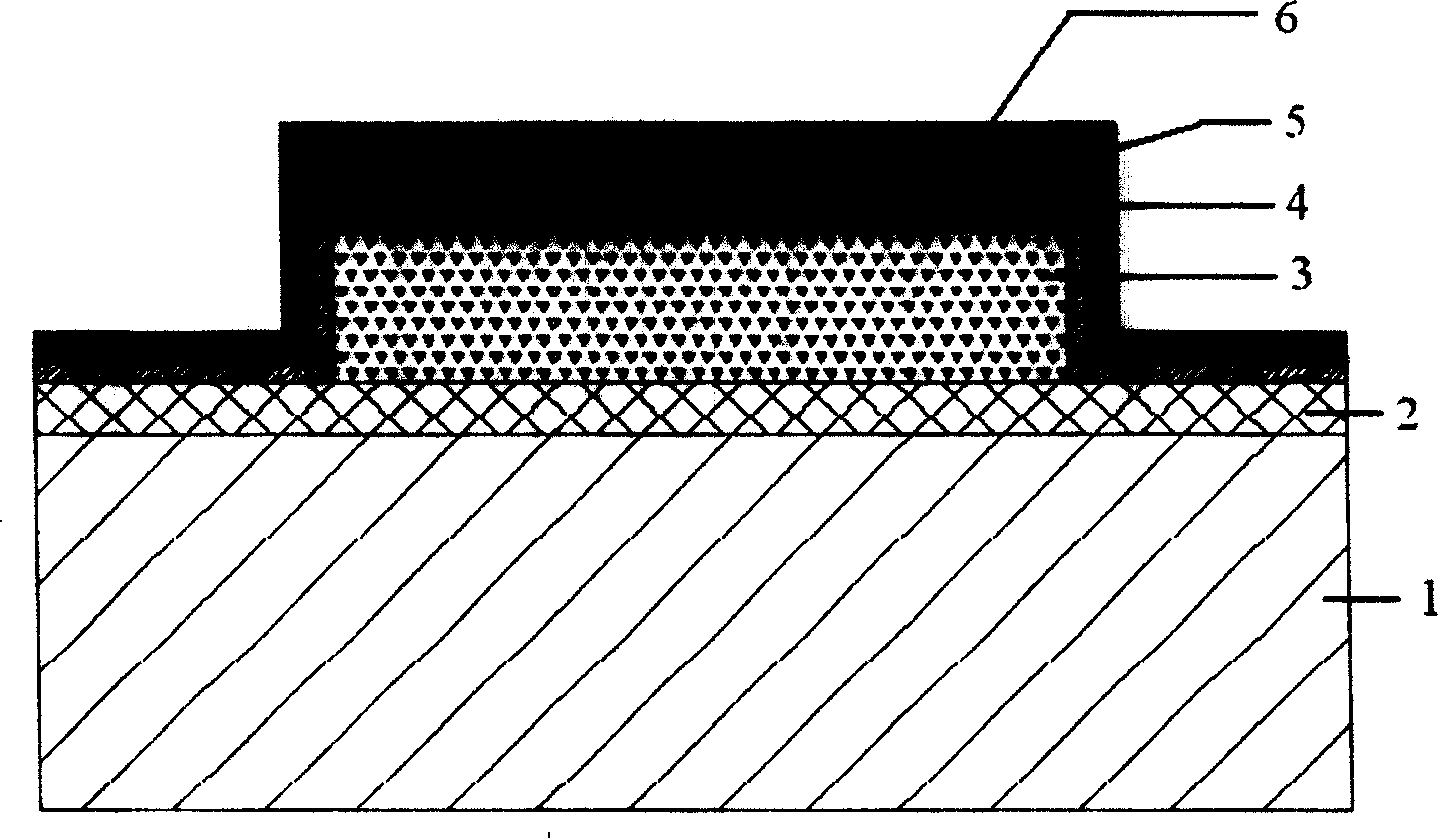

[0017] Preparation of epitaxial materials: N-type InP layer 2 with a thickness of 1 μm is sequentially grown on a semi-insulating InP substrate 1 with a thickness of 350 μm by molecular beam epitaxy technology, and the carrier concentration is greater than 2×10 18 cm -3 ; In with a thickness of 2.5 μm 0.53 Ga 0.47 As absorption layer 3; P-type InP layer 4 with a thickness of 0.5 μm and a carrier concentration greater than 2×10 18 cm -3 .

[0018] The specific preparation steps of micro-mesas and passivation layer are as follows:

[0019] 1. The above-mentioned epitaxial materials were ultrasonically cleaned with chloroform, diethyl ether, acetone, and ethanol in sequence, for more than 2 minutes each time, and dried with nitrogen gas.

[0020] 2. Positive photolithography, drying at 65°C for 40 minutes after ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com