Optical proximity correction figure for enhancing figure fidelity of Si/Ge emitter window

An optical proximity correction and emitter technology, which is applied in the photoplate making process of optics, pattern surface, and originals for opto-mechanical processing, etc., can solve problems such as unsatisfactory effect and poor fidelity, and improve Graphical fidelity, reduced cutoff frequency, and effects of changes in magnification factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

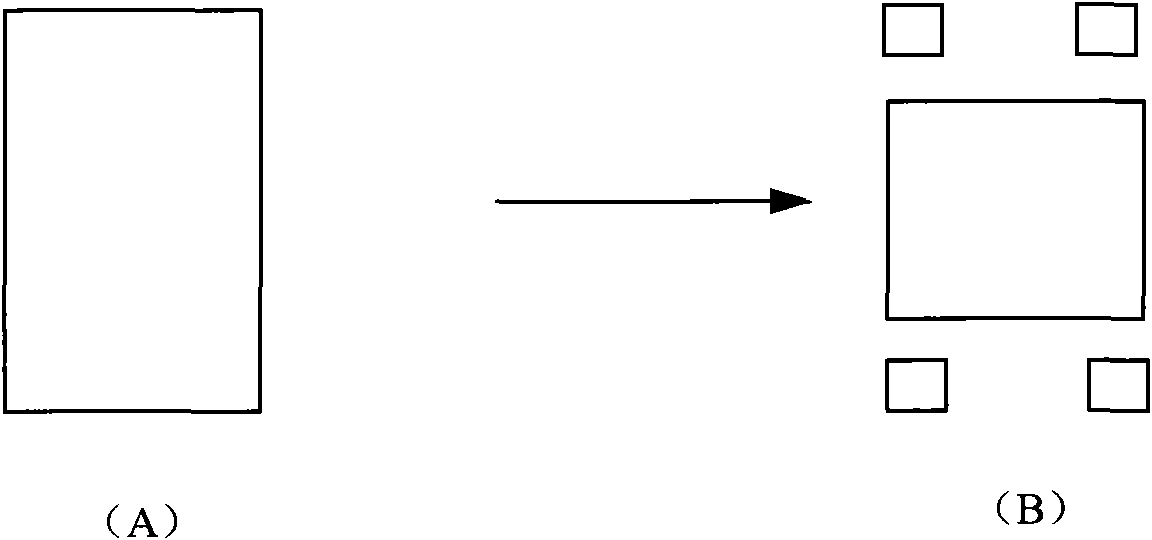

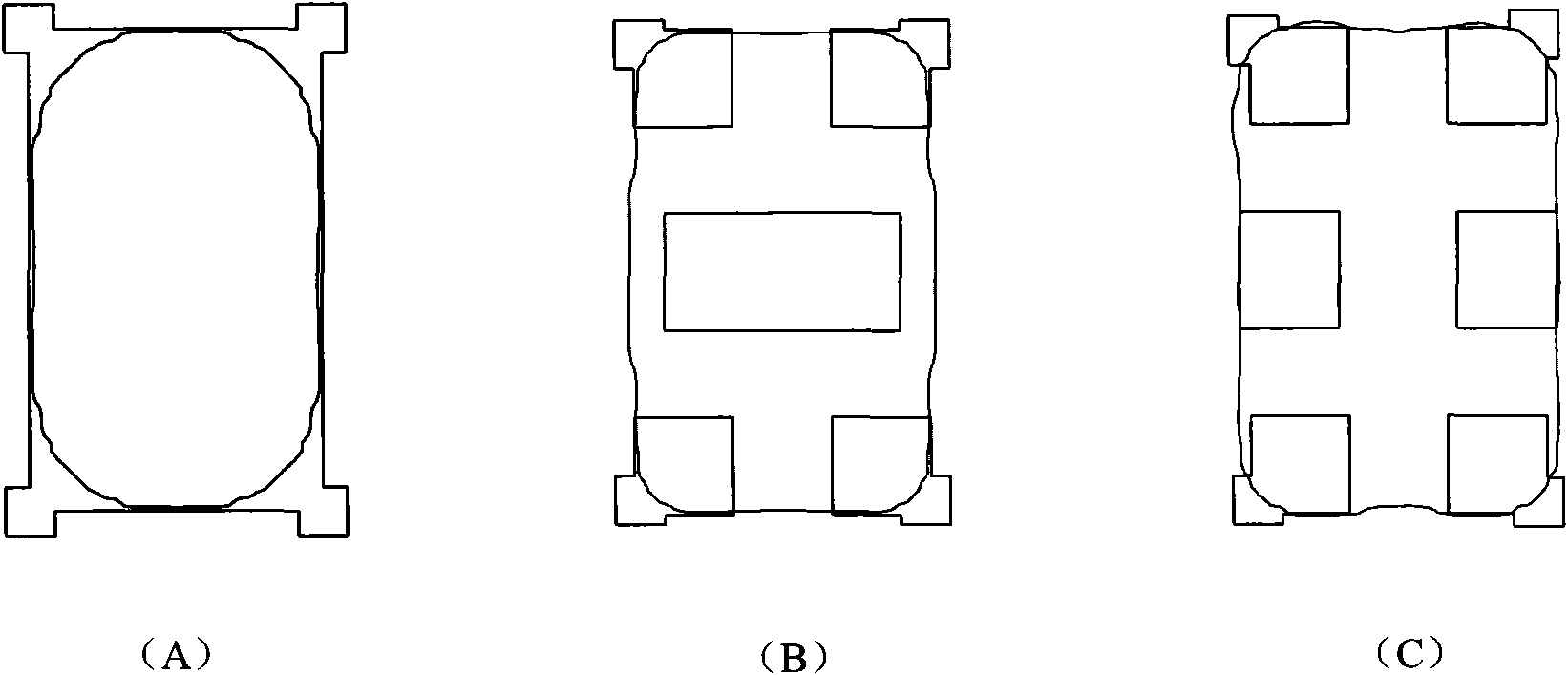

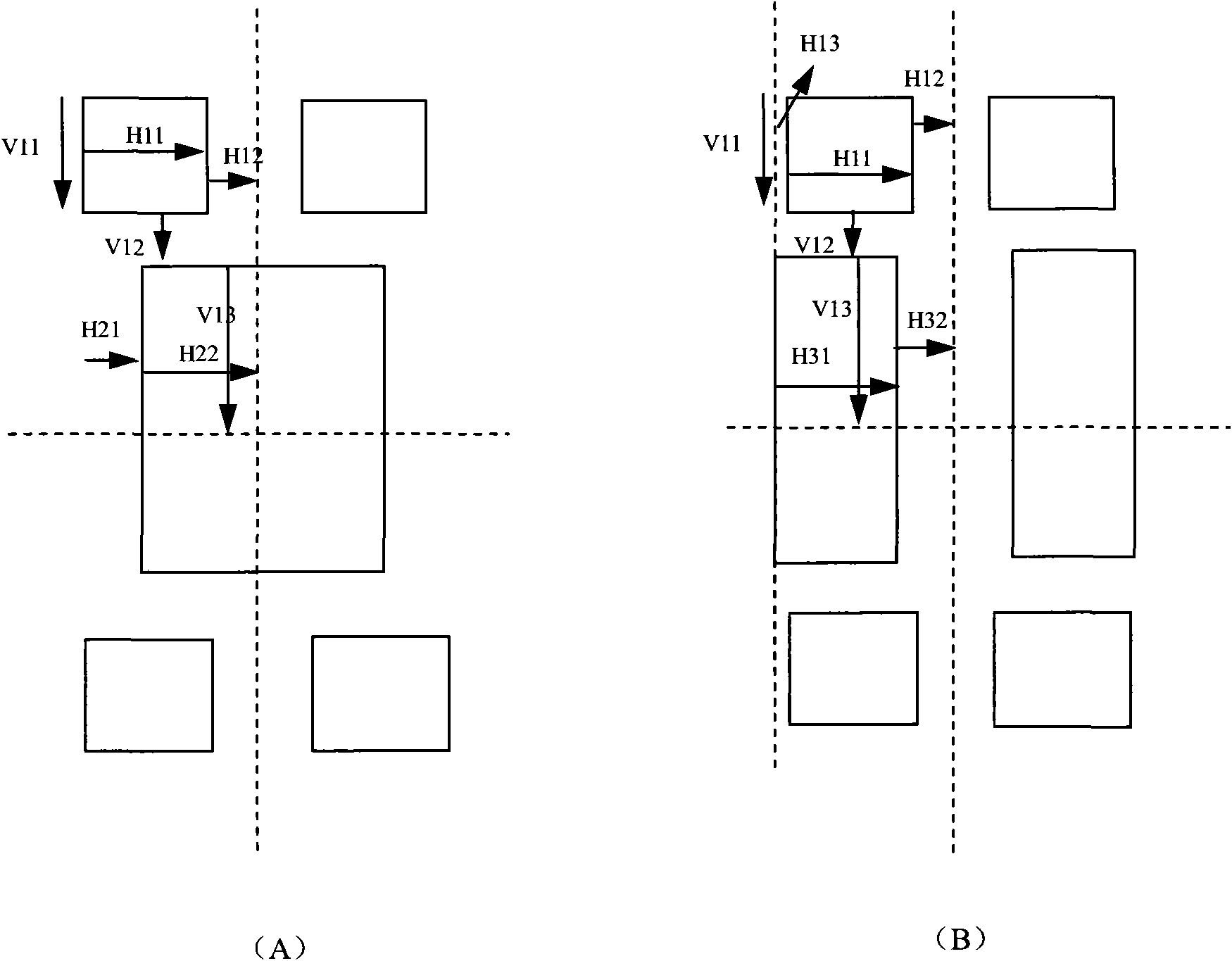

[0033] The invention provides an optical proximity correction pattern for improving the fidelity of the Si / Ge emitter window pattern, mainly using a series of small hole patterns to form the Si / Ge emitter window layout, and using smaller rectangles to generate corner rounding (corner rounding) The smaller the radius of curvature, the optical proximity effect principle, and the principle that the image cannot be imaged if the pitch is too small, the larger rectangle is split into small holes, the corner rounding is smaller after exposure, and the graphics are closer to the layout, while the middle After exposure, the separated area will have insufficient resolution, and the side lobe (side lobe, side lobe) effect will occur on the edge of the small hole when the hole is overexposed, resulting in the principle of pattern adhesion, so that it will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com