Miniature optical anti-vibration camera module

A camera module and optical anti-shake technology, which is applied in the field of cameras, can solve the problems of difficult assembly process of micro-optical anti-shake camera module and reduced reliability of micro-motor structure, and achieve lightweight product structure, low power consumption, and structural Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

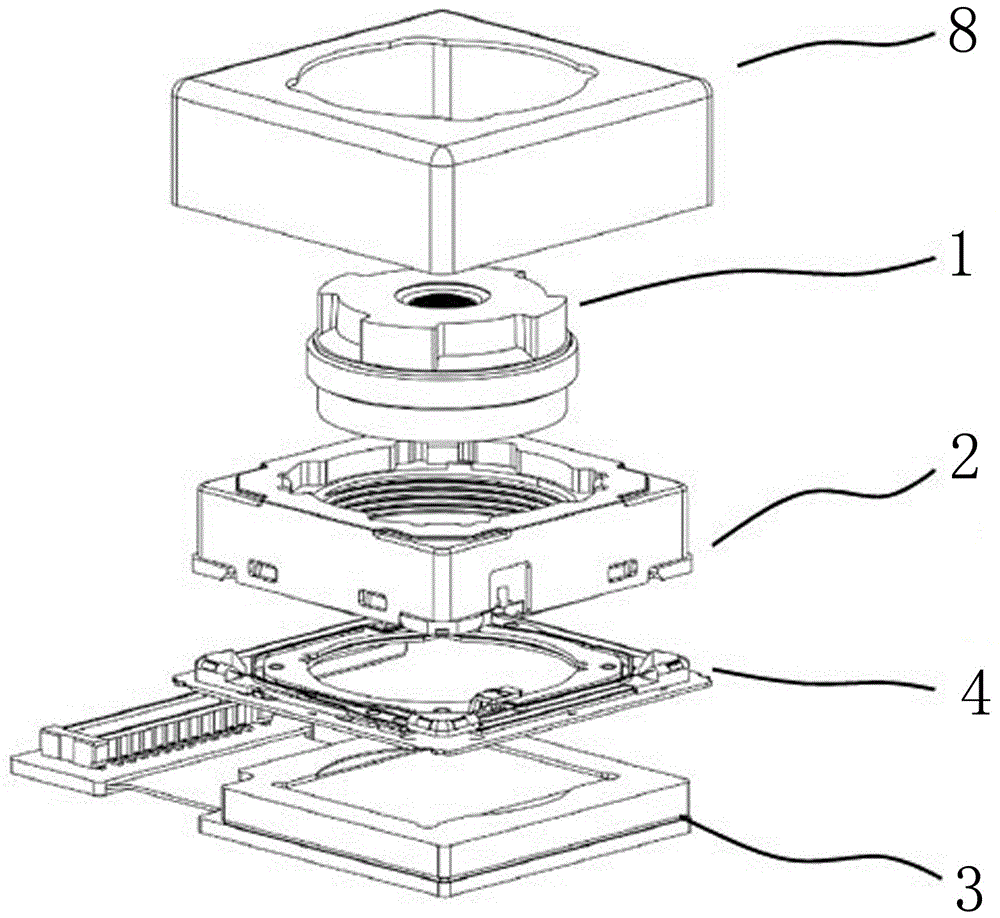

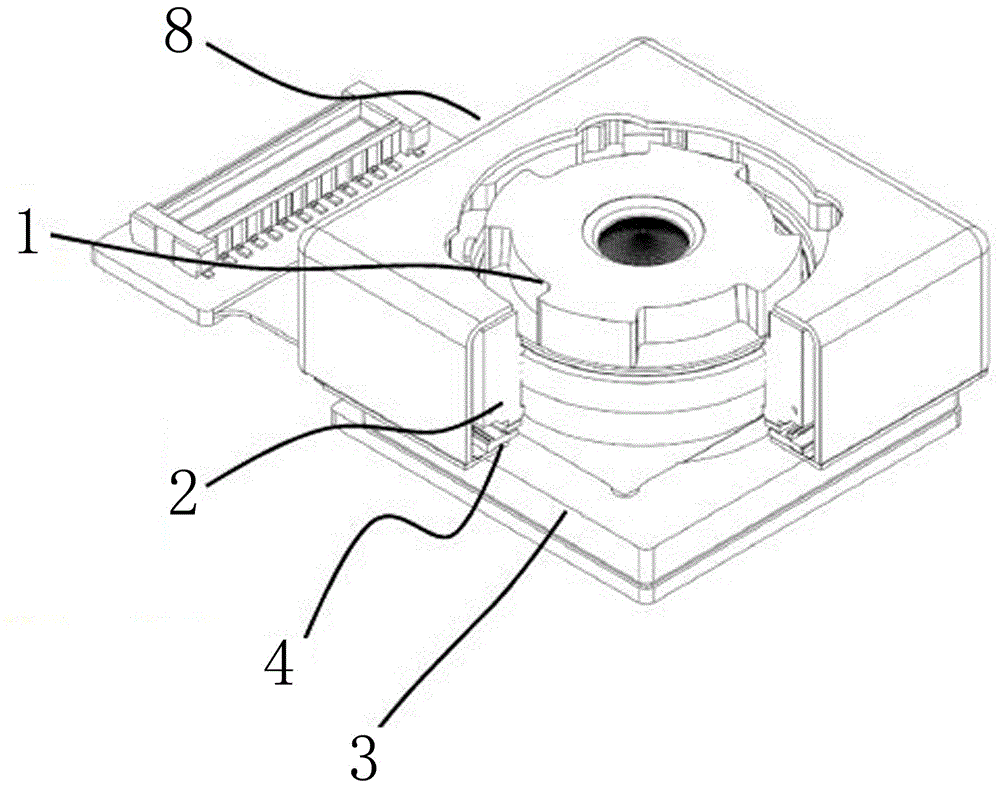

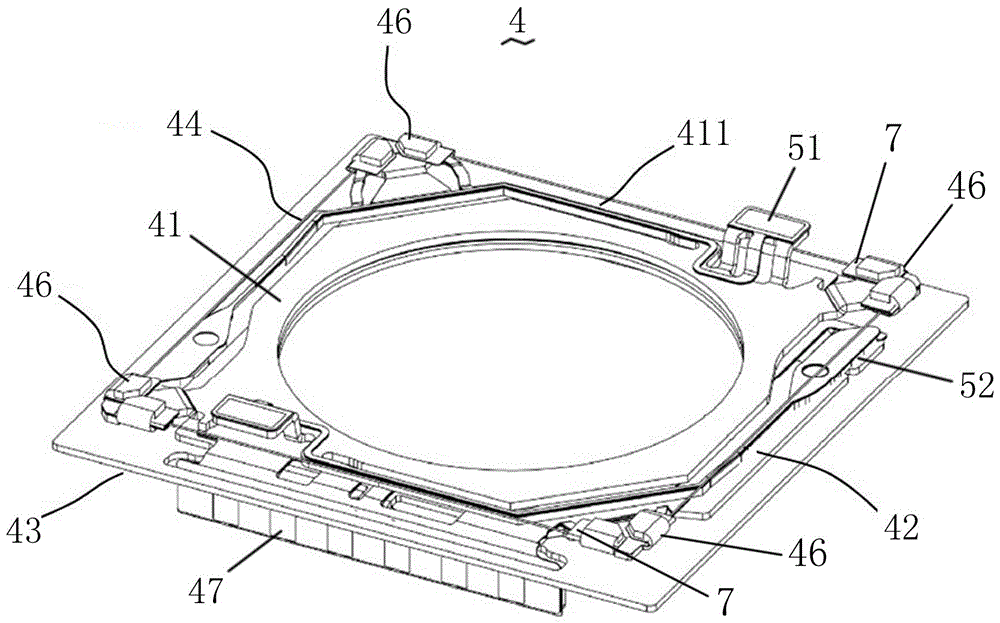

[0029] refer to Figure 1~7 As shown, the present invention relates to a miniature optical anti-shake camera module, which has a protective outer cover 8, a lens 1, an auto-focus voice coil motor 2, an image sensor module 3, and a micro-memory alloy optical anti-shake actuator 4 , the lens 1 is fixed on the auto-focus voice coil motor 2, the micro-memory alloy optical anti-shake actuator 4 has a lens mounting hole adapted to the lens 1, and the image sensor module 3 transmits the image acquired by the lens 1. The auto-focus voice coil motor 2 is fixed on the miniature memory alloy optical anti-shake actuator 4, and the control chip pulls the auto-focus voice coil motor based on the length change of the memory alloy wire on the mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com