clutch slave cylinder

A clutch and linear movement technology, applied in clutches, mechanical drive clutches, fluid drive clutches, etc., can solve the problems of expensive structure space, inability to absorb radial force and vibration of angular contact ball bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

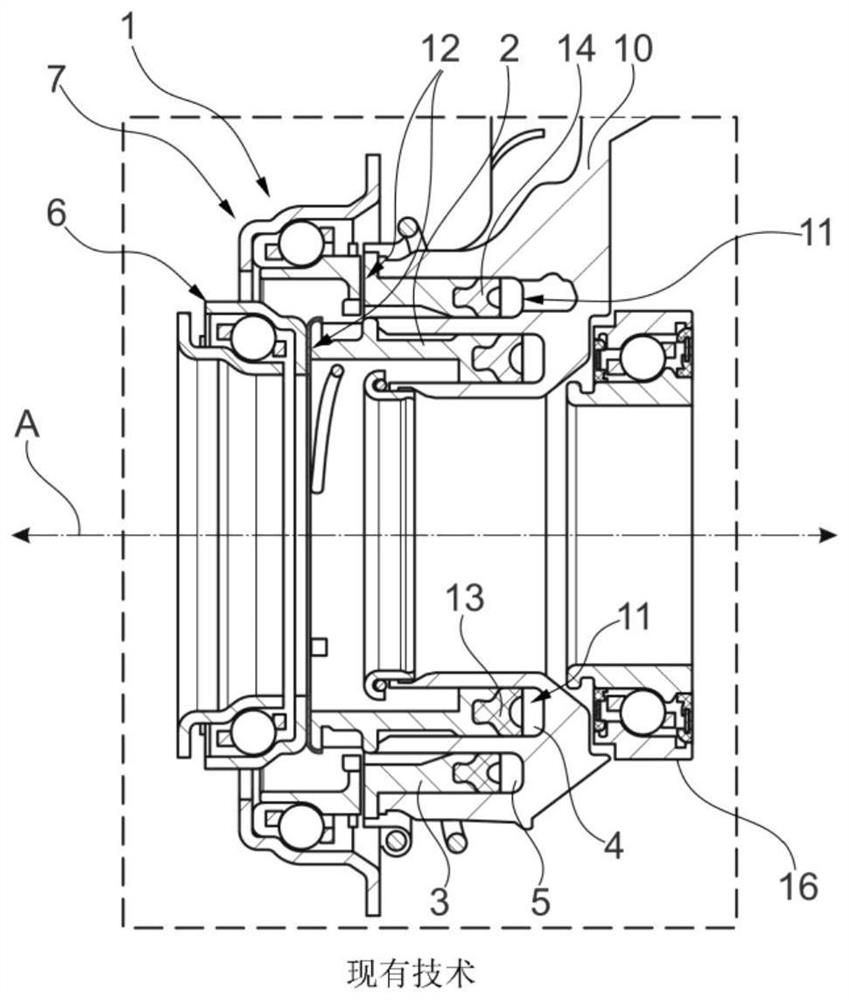

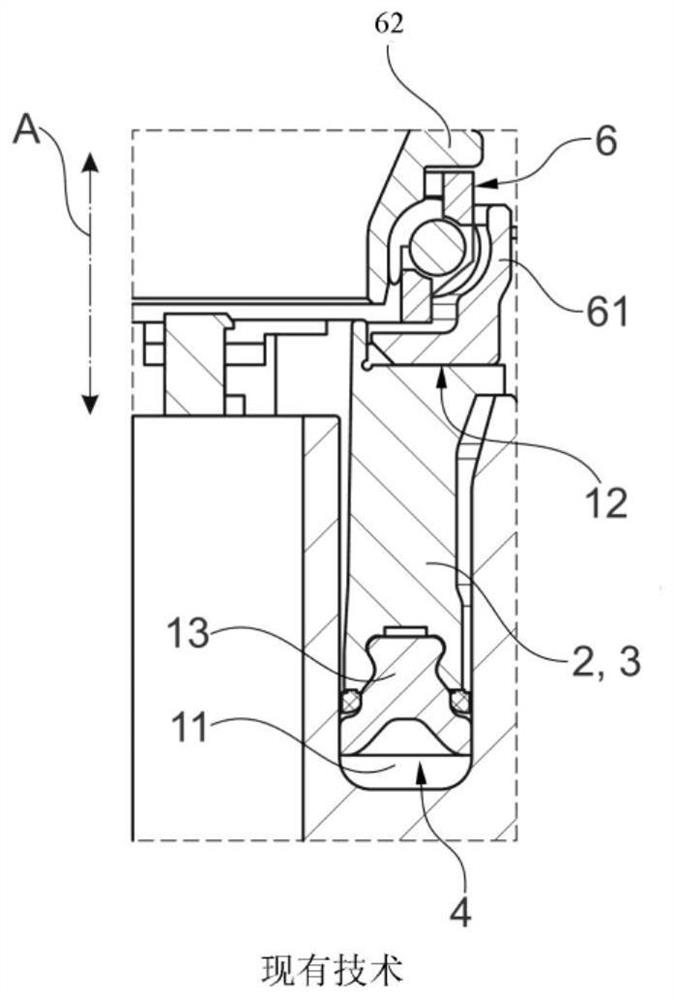

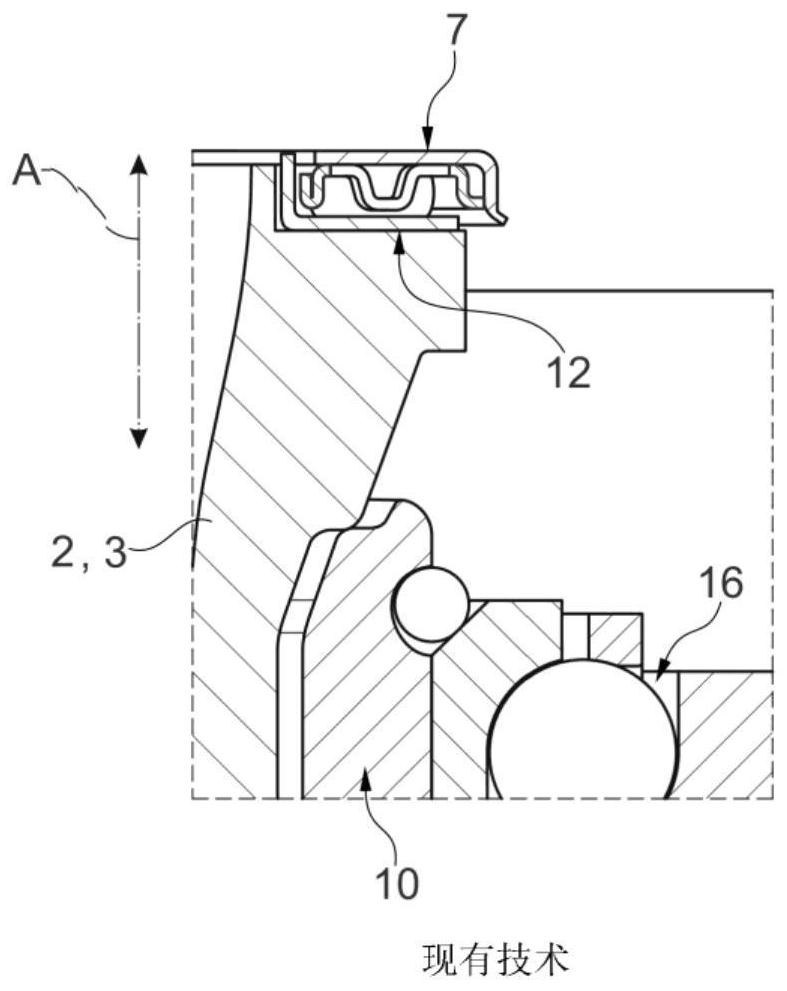

[0029] figure 1 A cross-sectional view of a clutch slave cylinder 1 according to the prior art is shown. The clutch slave cylinder 1 comprises at least one first annular piston 2 which is linearly displaceable in the direction of the axis A in a first pressure chamber 4 formed in the housing 10 . Likewise, a second annular piston 3 is provided, which is also linearly displaceable along the axis A in the second pressure chamber 5 formed in the housing 10 . The first annular piston 2 carries a first sealing ring 13 at the first end 11 . Likewise, the second annular piston 3 carries a second sealing ring 14 at the first end 11 . The first sealing ring 13, 14 serves to seal the pressure chamber 4 or 5 so that no pressurized fluid can escape from the system. A first annular actuating bearing 6 is arranged on the second end 12 of the first annular piston 2 . Likewise, a second annular actuating bearing 7 is provided on the second end 12 of the second annular piston 3 . The hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com