A LED driver with strobe, constant power mode

A technology of LED driver and constant power mode, applied in the field of LED driver, can solve the problems of waste of electric energy and high energy consumption of LED lamps, and achieve the effect of avoiding excessive power consumption and ensuring the effect of supplementary light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

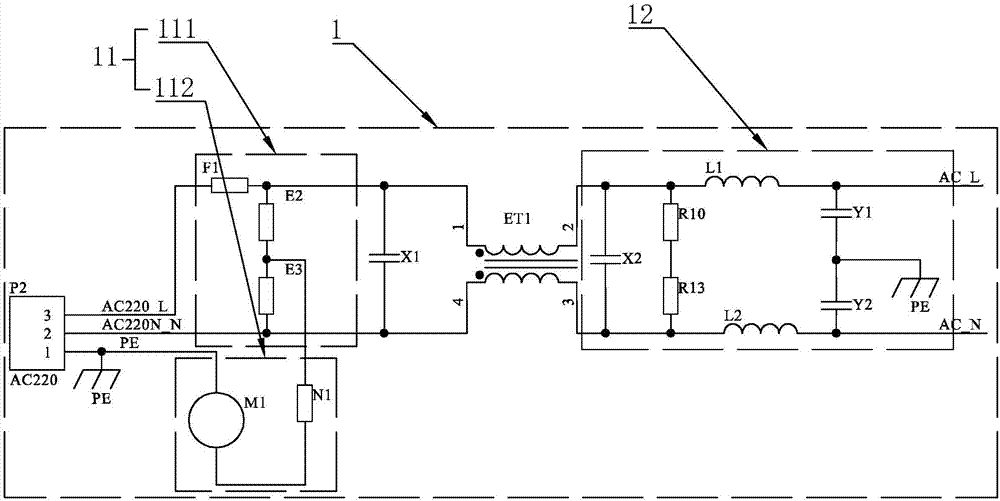

specific Embodiment approach

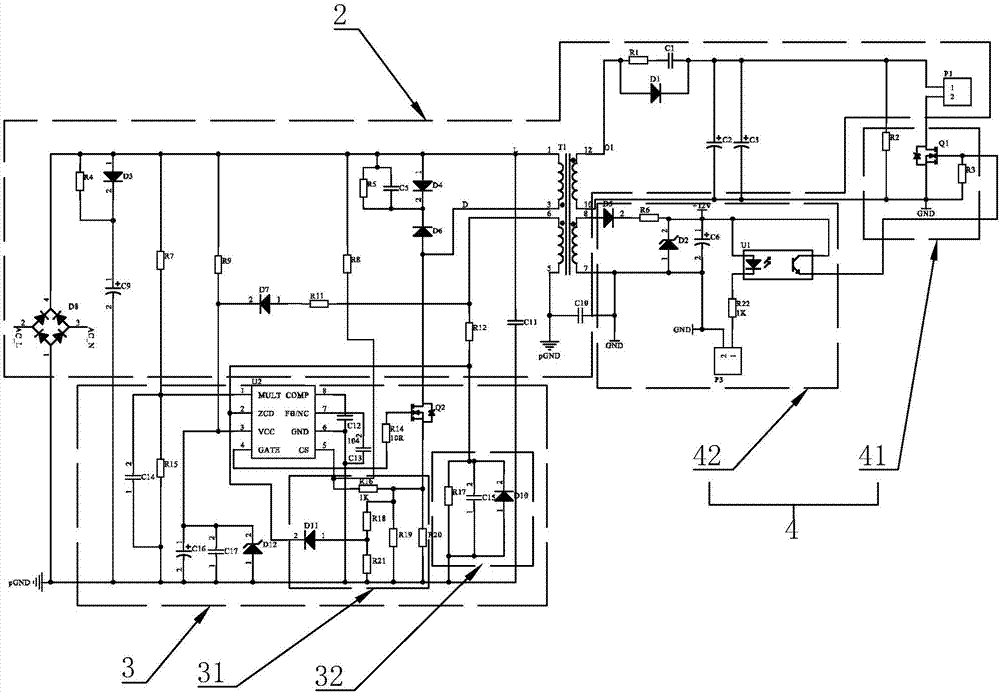

[0043] As an improved specific implementation, the strobe control circuit 4 includes:

[0044] The switch circuit 41 is coupled between the power conversion circuit 2 and the LED lamp, so as to control the on-off between the power conversion circuit 2 and the LED lamp;

[0045] The signal conversion circuit 42 is coupled to the external camera controller, and is also coupled to the switch circuit 41, so as to input the strobe signal output by the external camera controller into the switch circuit 41 to control the on-off of the switch circuit 41, through the switch The setting of the circuit 41 can effectively realize the on-off control between the power conversion circuit 2 and the LED light, and the setting of the signal conversion circuit 42 can effectively realize the signal conversion of the control camera output by the external camera controller. In this way, the switching circuit 41 and the signal conversion circuit 42 cooperate to effectively realize the effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com