Light guide plate, light guide plate manufacturing method, backlight LED module, display and panel lamp

A technology of light guide plate and backlight source, applied in the field of light guide plate for lighting or display and its preparation, can solve the problems of inability to achieve light guide effect, low uniformity and brightness, low light output efficiency, etc., to meet the requirements of optical design and production. The effect of low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The light guide plate of this embodiment includes a light guide plate base material, the light guide plate base material is provided with a light incident surface, a light exit surface and a bottom surface, the light exit surface is opposite to the bottom surface, and a layer containing a light guide surface is printed on the light exit surface. The ink film layer of the light particles, the density of the light guide particles in the ink film layer is distributed according to the law of gradually increasing from close to the light source to away from the light source, so as to obtain uniform light output brightness on the light output surface.

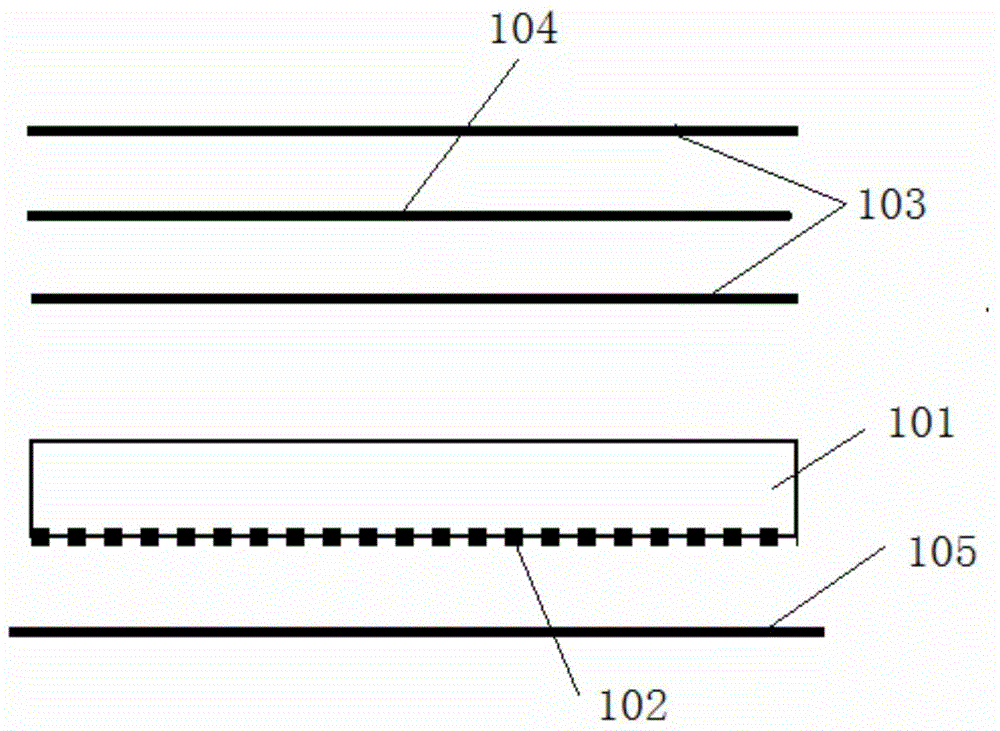

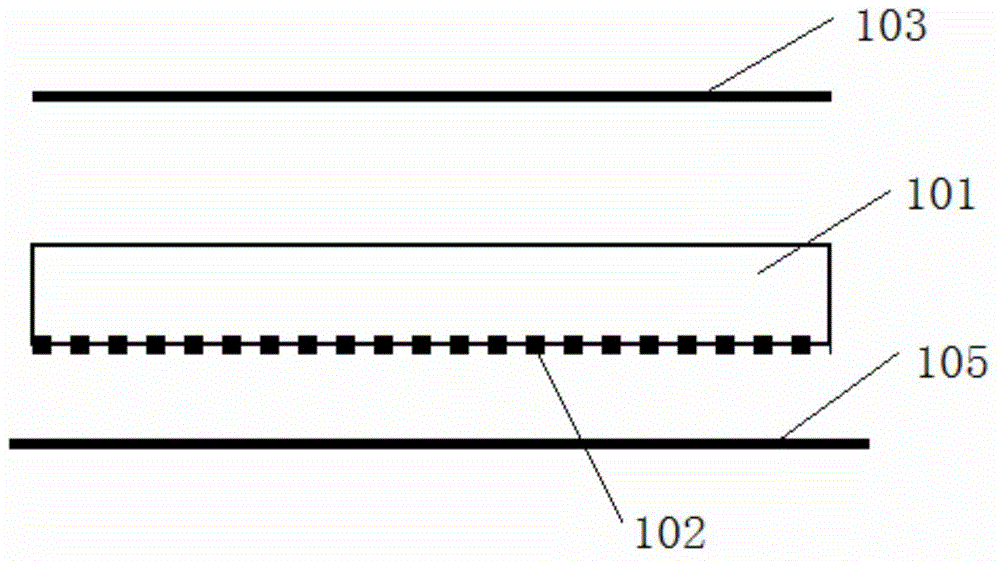

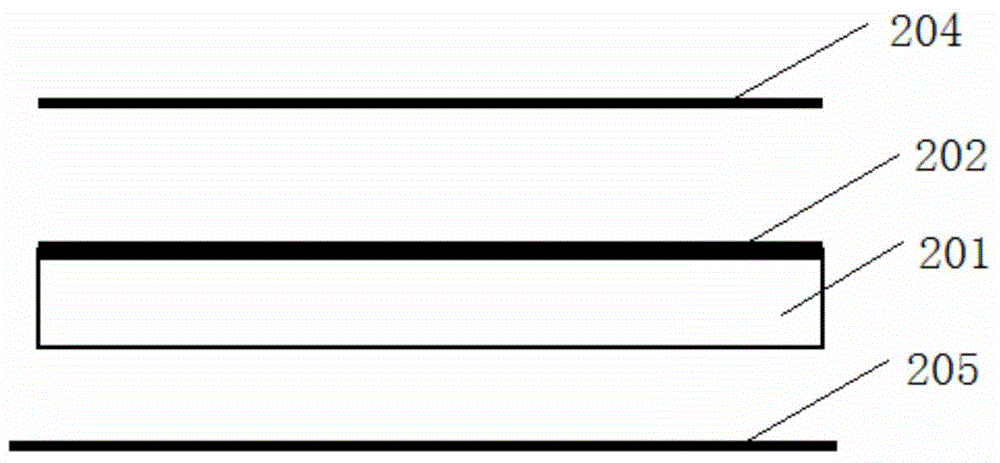

[0059] like image 3 and Figure 4 As shown, are respectively the structural schematic diagrams of the light guide plate of this embodiment when applied in LED displays and LED panel lights, and figure 1 and figure 2 Compared with the existing technology, the structure is simplified a lot, for example, there is no need to ar...

Embodiment 2

[0080] The difference between this embodiment and Embodiment 1 lies in that the ink film layer is arranged on the bottom surface of the light guide plate, and other structures can adopt the same structure as Embodiment 1, which will not be repeated here. Compared with Embodiment 1, in this embodiment, a less part of the light entering from the line light source passes through the ink film layer and then directly exits the light emitting surface, while more light exits through the ink film layer after several times of total reflection.

Embodiment 3

[0082] This embodiment is the preparation method of the light guide plate of embodiment 1 and embodiment 2, and its process flow chart is as follows Figure 13 As shown, it mainly includes:

[0083] Step 100 of designing an optical gray scale image, step 200 of making a printing roller 3 , step 300 of preparing printing ink, and step 400 of printing a light guide plate. Wherein, the printing light guide plate step 400 further includes:

[0084] Ink adhesion step 401, that is, rotating the printing roller 3 to make the printing image adhere to the printing ink;

[0085] Ink scraping step 402, that is, the ink scraper 2 scrapes the ink in the non-printing area;

[0086] Transfer printing ink to pad printing roller step 403, that is, transfer the printing pattern to the pad printing rubber roller 5 (the pad printing rubber roller 5 and the printing roller 3 move in the opposite direction);

[0087] Printing step 404, that is, transfer the pattern to the light guide plate subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com