A led lighting fixture

一种LED照明、LED模块的技术,应用在照明装置、照明和加热设备、照明装置的零部件等方向,能够解决装配及应用困难、灯具臃肿等问题,达到散热方式新颖、散热性能改良、散热效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, features and effects of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, other embodiments obtained by those skilled in the art without creative efforts belong to The protection scope of the present invention.

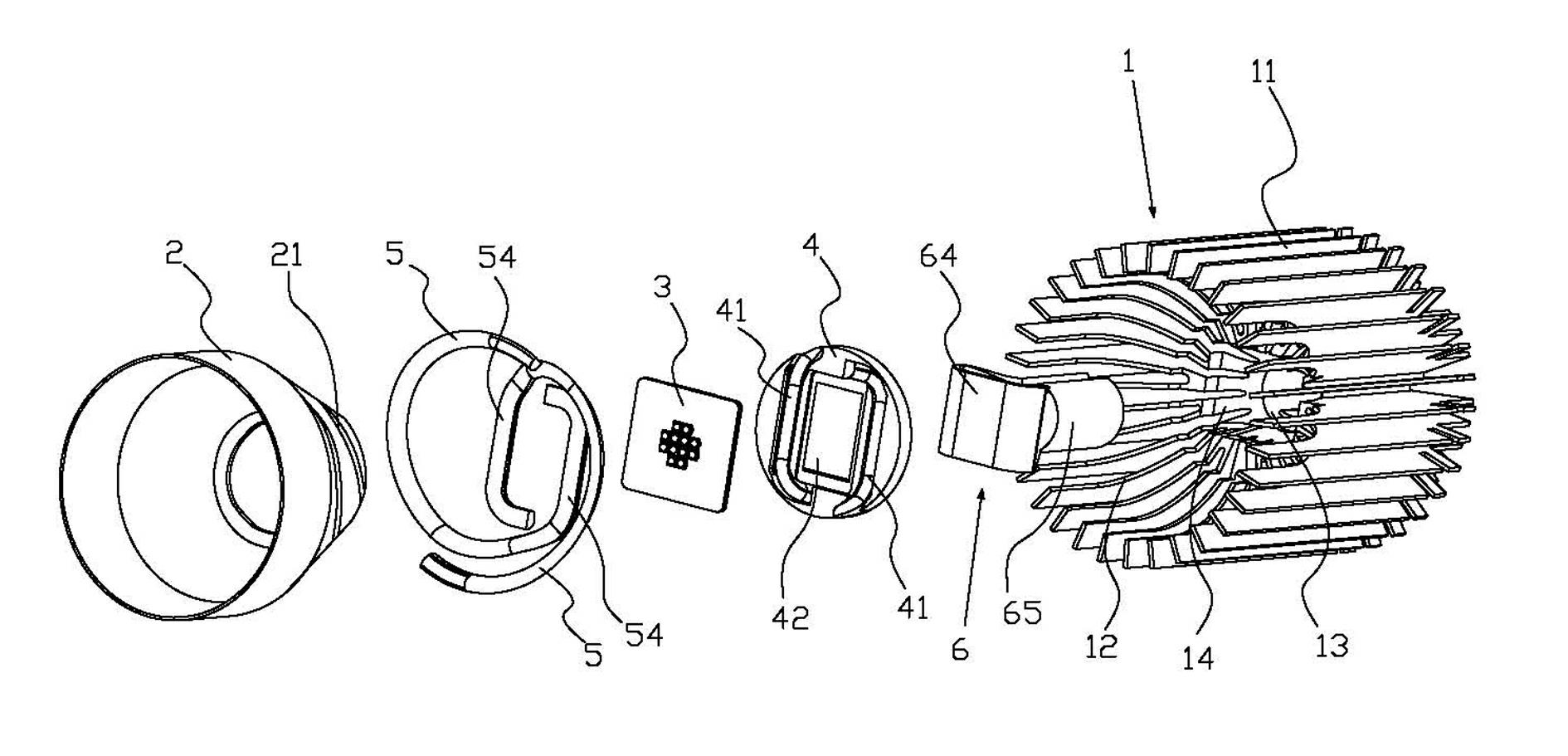

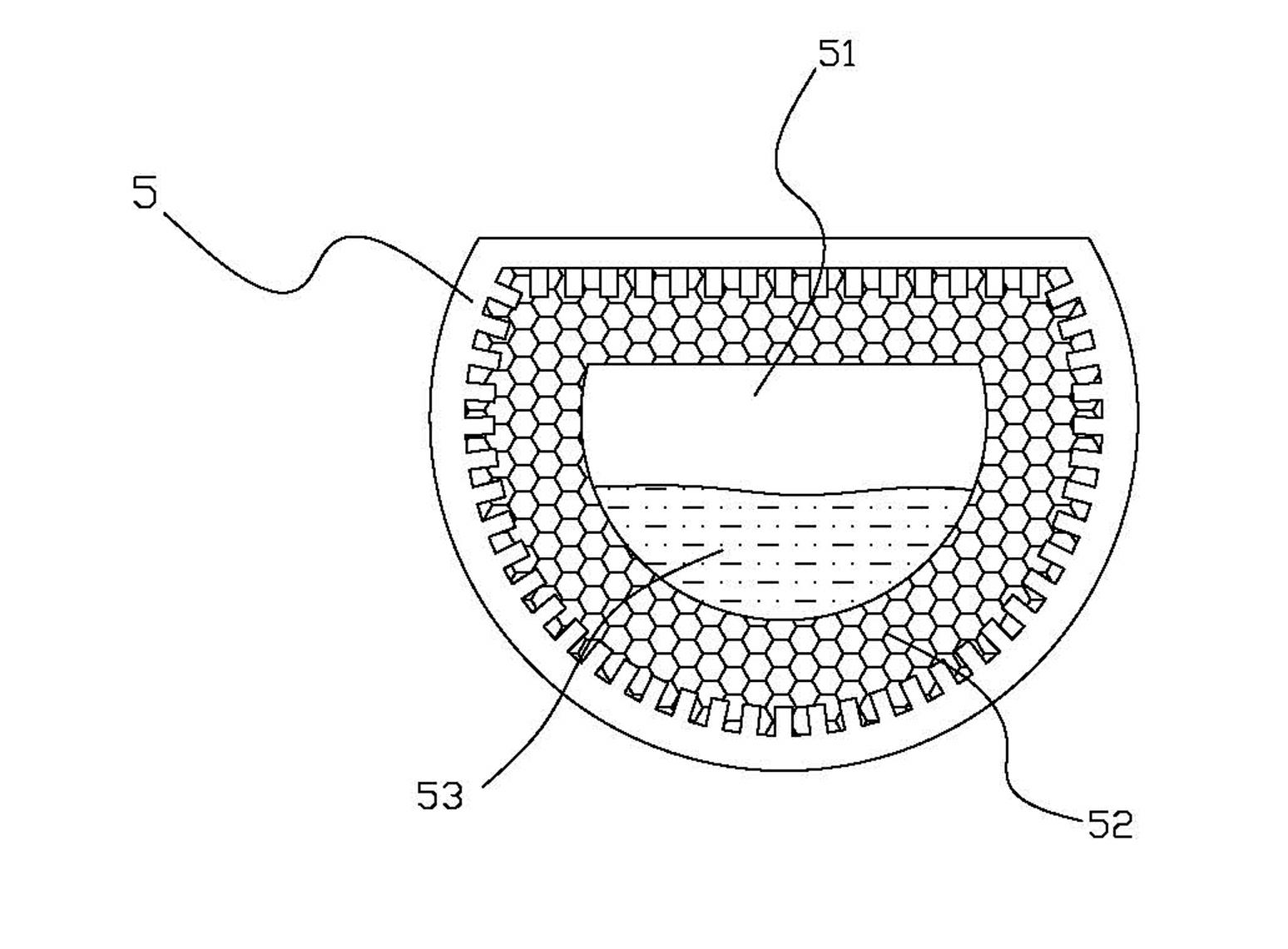

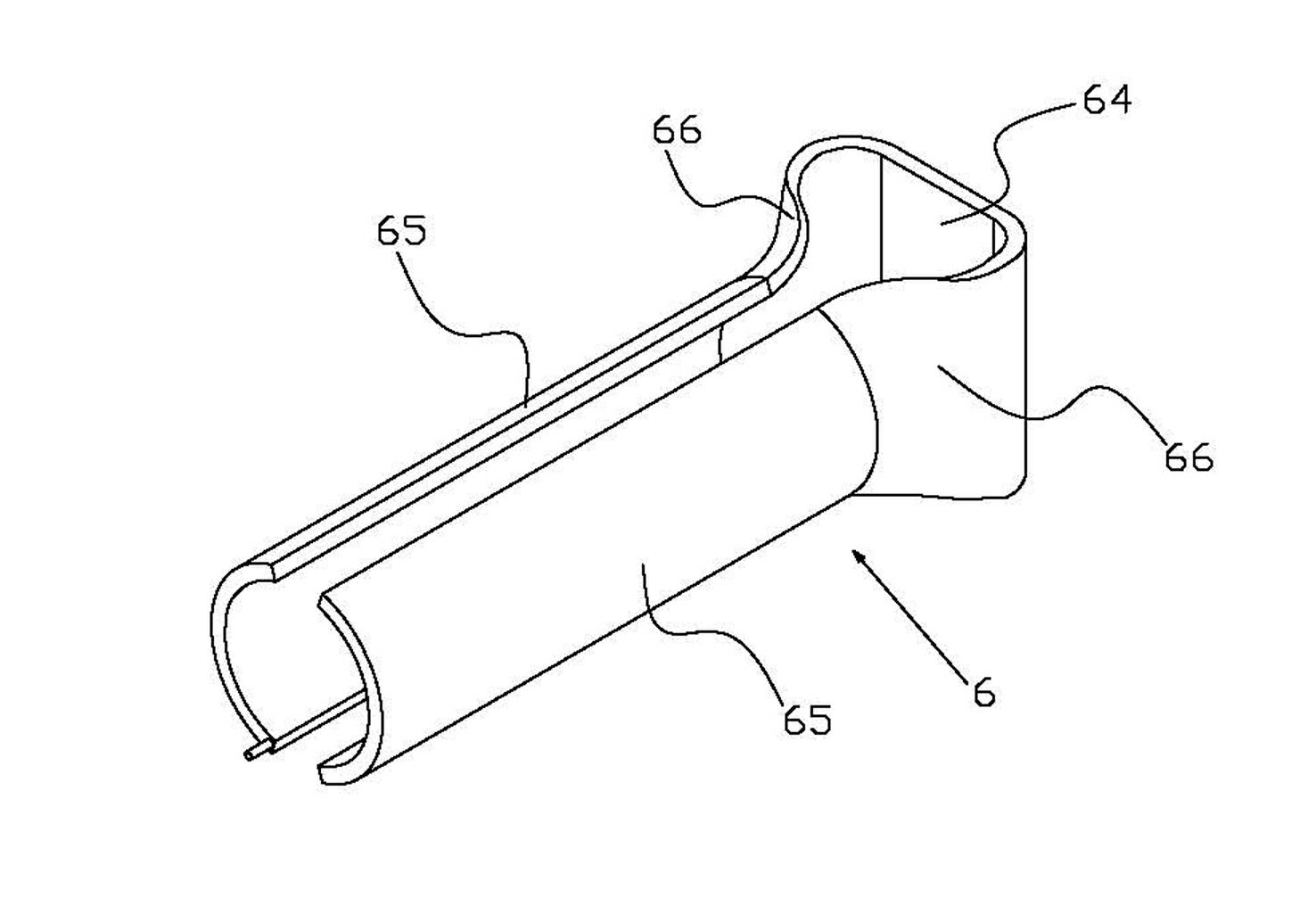

[0029] refer to figure 1 , an LED lighting fixture disclosed in the present invention, its specific structure includes a heat sink 1 , a reflector 2 , an LED module 3 , a support member 4 , a heat pipe 5 , and a vapor chamber 6 . The function of the heat sink 1 is to dissipate heat from the lamp, and it consists of a central hole and a plurality of heat sinks 11 arranged around the center hole, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com