Bireflection light emitting diode

A technology of light-emitting diodes and reflective surfaces, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as unfavorable light output efficiency, and achieve the effect of increasing light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

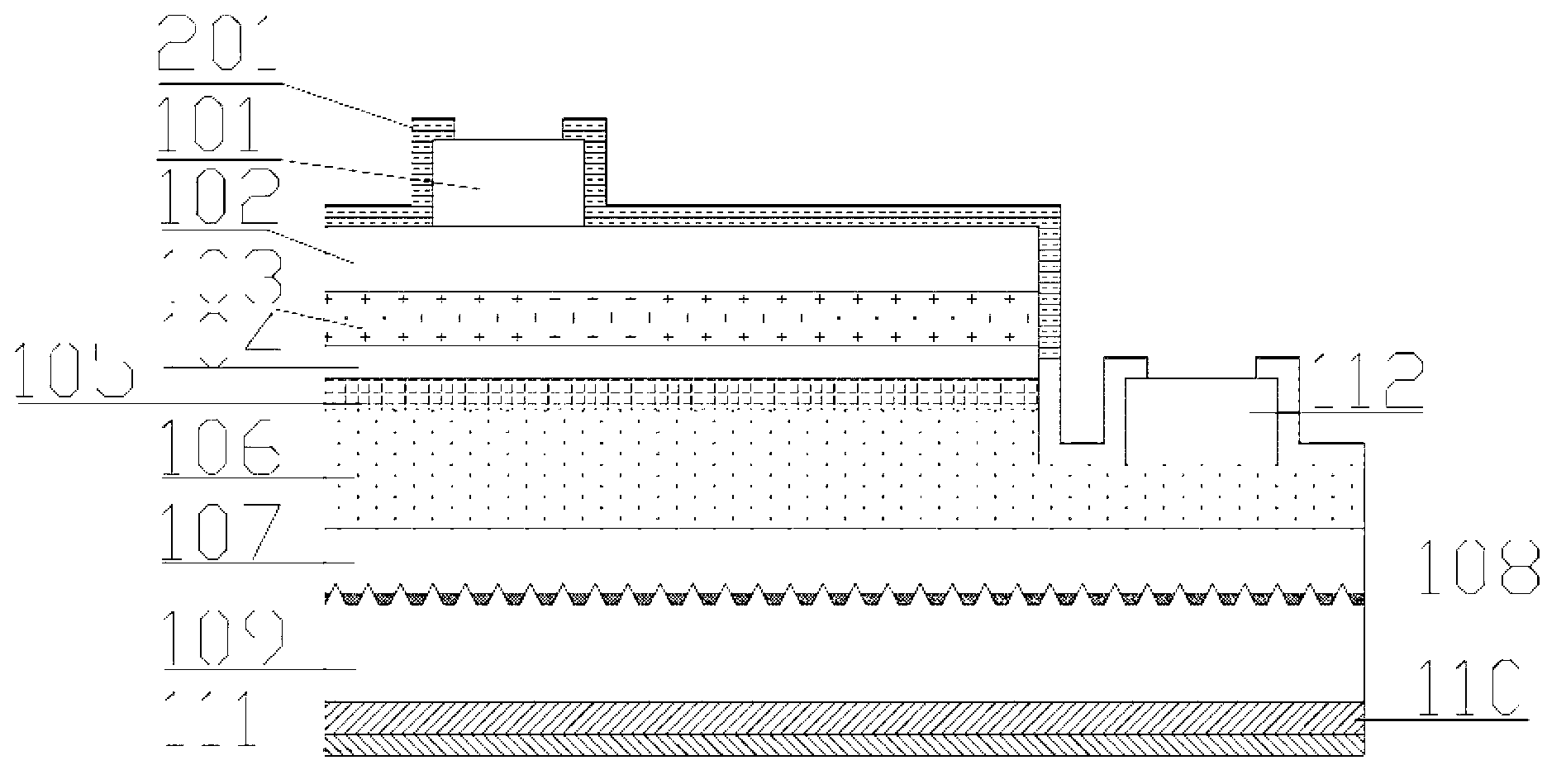

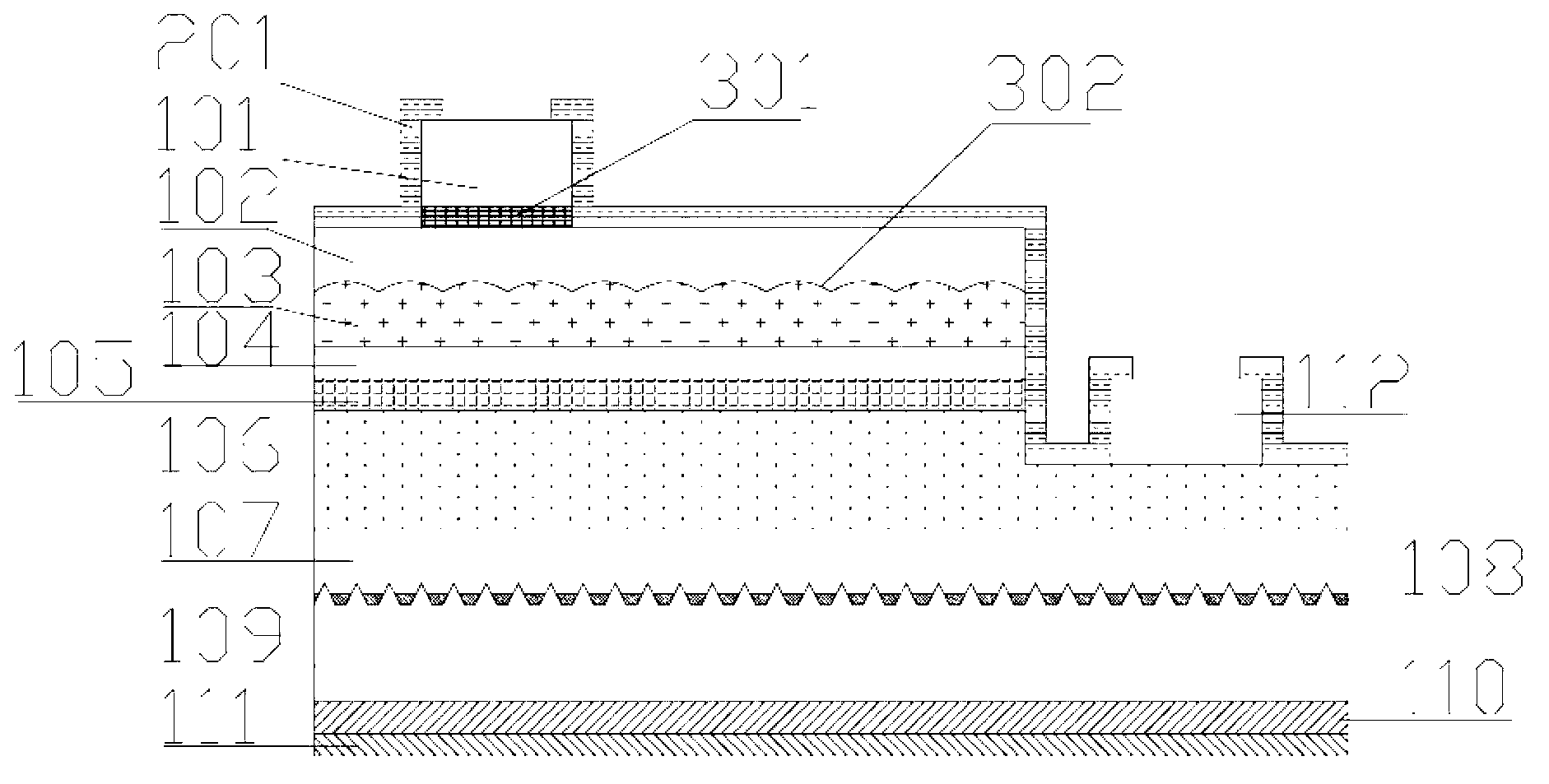

[0026] Embodiment 1: as figure 2 As shown, the current spreading layer 102 is used for double reflection.

[0027] The first light reflecting surface 301 is located between the lower surface of the P electrode 101 and the upper surface of the current spreading layer 102 , and the second light reflecting surface 302 is located between the lower surface of the current spreading layer 102 and the upper surface of the P-type layer 103 .

[0028] A preferred embodiment of the first light reflection surface 301 is a newly added Bragg reflection layer between the lower surface of the P electrode 101 and the upper surface of the current spreading layer 102, that is, a multilayer structure in which SiO2 and TiO2 are alternately combined, such that Reflection works best. Alternatively, the first light reflection surface 301 can also be an omnidirectional reflection layer, or a newly added layer of Ag or Al, which has better reflection effect; or, the first reflection surface 301 itsel...

Embodiment 2

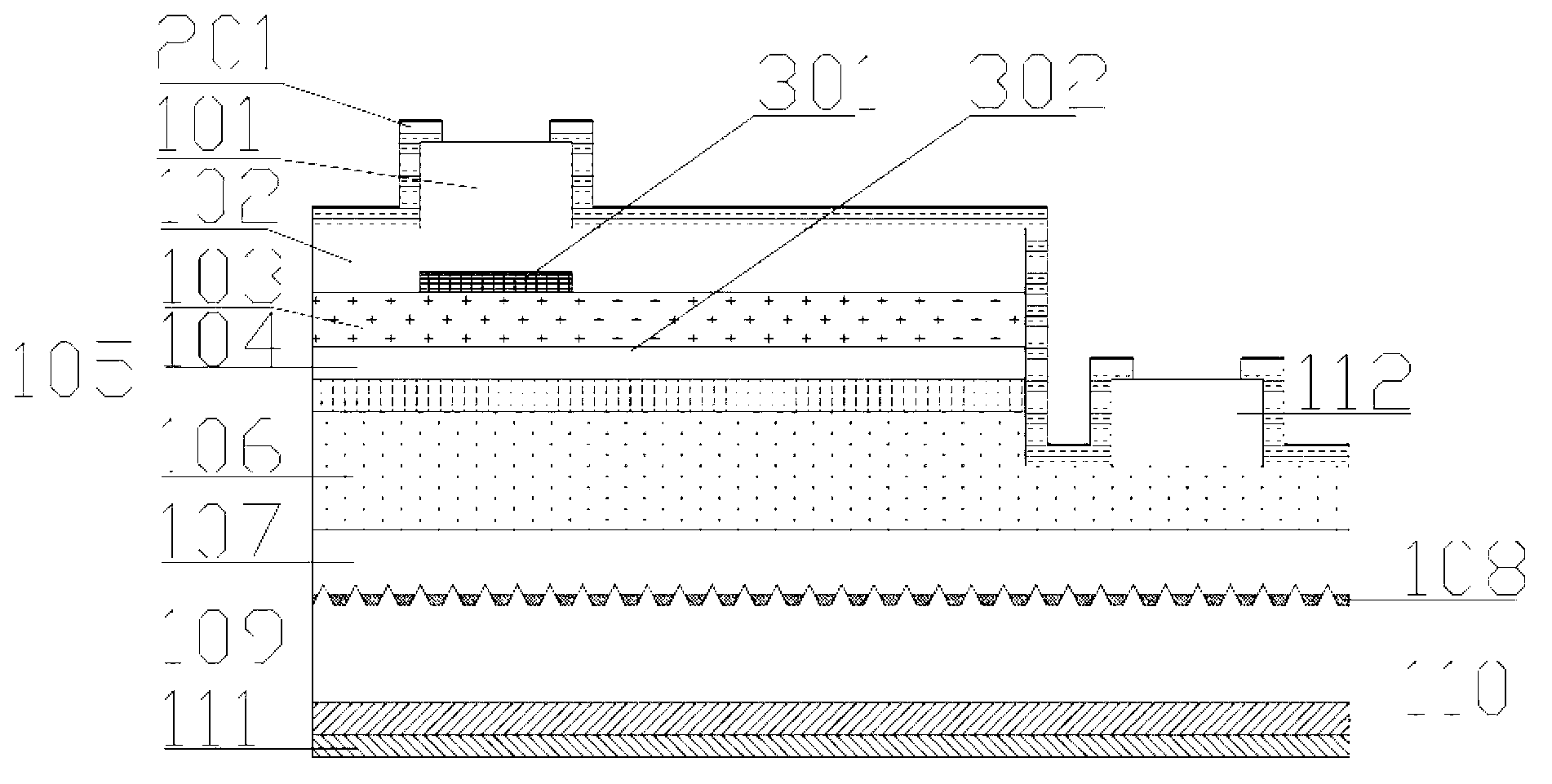

[0031] Embodiment 2: as image 3 As shown, the P-type layer 103 is used for double reflection.

[0032] The first light reflecting surface 301 is located between the lower surface of the current spreading layer 102 and the upper surface of the P-type layer 103 , and the second light reflecting surface 302 is located between the lower surface of the P-type layer 103 and the upper surface of the active layer 105 .

[0033] The preferred embodiment of the first light reflecting surface 301 is also a newly added Bragg reflective layer; if this is the case, it is further preferred to describe a solution similar to that in Example 1, that is, the area of the newly added Bragg reflective layer is greater than or equal to the P electrode The area of the lower surface of the P electrode 101 is smaller than the area of the lower surface of the current spreading layer 102, and the projection of the lower surface of the P electrode 101 on the Bragg reflection layer falls completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com