A heat-storing waterproof and moisture-permeable outdoor down cold-proof clothing fabric and its preparation method

A technology of waterproof, moisture-permeable and cold-proof clothing, which is applied in the field of textiles and clothing. It can solve the problems of dust on the finished garment and the down that is easy to drill out of the fabric, and achieve the effects of improving uniformity, overcoming electrostatic phenomena such as polar fleece, and superior moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

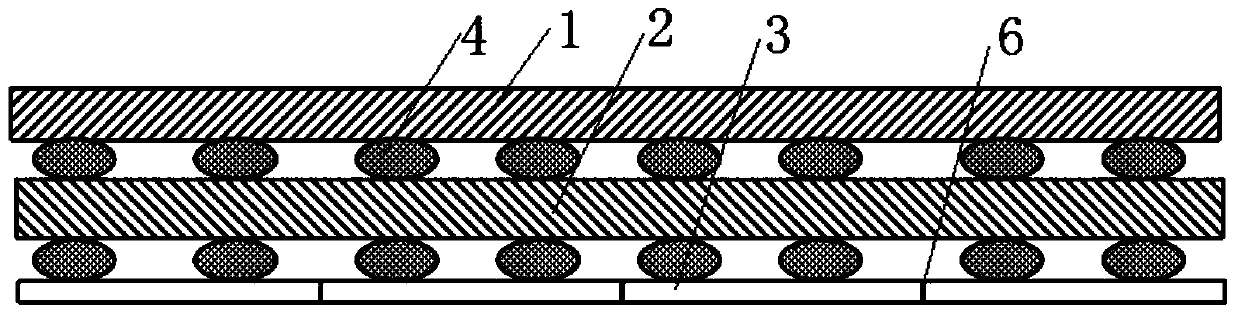

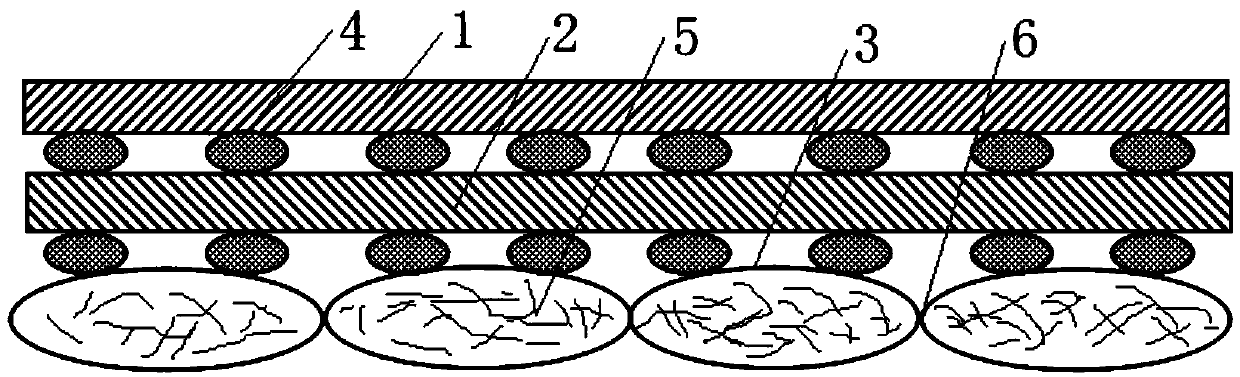

[0034] Such as figure 1 As shown, the cold-proof clothing fabric includes a waterproof layer 1, a waterproof, moisture-permeable heat storage PU film 2, and a nylon fabric layer 3 from the outside to the inside; The contact surfaces of the PU film 2 and the nylon fabric layer 3 are compounded with an adhesive 4 .

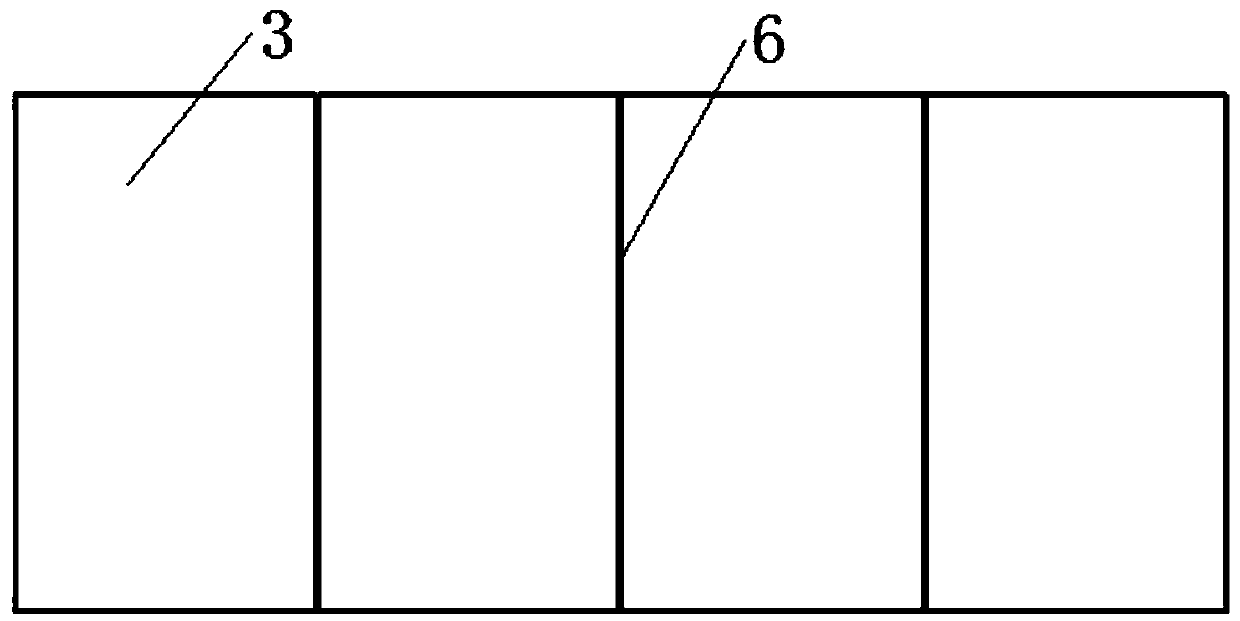

[0035] The bonding between the layers adopts point-shaped hot-melt compounding, and the adhesive 4 uses PU glue; the base fabric of the waterproof layer is woven from 30D polyester yarn; the water-repellent effect of the waterproof layer reaches more than 90 points; the nylon fabric layer is It consists of a plurality of evenly distributed double-layer quilted nylon fabric bile ducts; the plurality of bile ducts are arranged in parallel, and the sides of two adjacent bile ducts are connected at the connection point 6 .

[0036] This embodiment also discloses the preparation method of the above-mentioned heat-storing, waterproof, and moisture-permeable outdoor down ...

Embodiment 2

[0041] Such as figure 1 As shown, the cold-proof clothing fabric includes a waterproof layer 1, a waterproof, moisture-permeable heat storage PU film 2, and a nylon fabric layer 3 from the outside to the inside; The contact surfaces of the PU film 2 and the nylon fabric layer 3 are compounded with an adhesive 4 .

[0042] The bonding between the layers adopts point-shaped hot-melt compounding, the adhesive 4 is made of PU glue, and the base fabric of the waterproof layer is woven from 30D nylon yarn. The water-repellent effect of the waterproof layer reaches more than 90 points. The nylon fabric layer is composed of multiple uniformly distributed double-layer non-quilted nylon fabric bile ducts, the plurality of bile ducts are arranged in parallel, and the sides of two adjacent bile ducts are connected at the connection point 6 .

[0043]In this embodiment, the preparation method of the heat-storing, waterproof, and moisture-permeable outdoor down winter clothing fabric inclu...

Embodiment 3

[0046] Such as figure 1 As shown, the cold-proof clothing fabric includes a waterproof layer 1, a waterproof, moisture-permeable heat storage PU film 2, and a nylon fabric layer 3 from the outside to the inside; The contact surfaces of the PU film 2 and the nylon fabric layer 3 are compounded with an adhesive 4 .

[0047] The bonding between the layers adopts point-shaped hot-melt compounding, the adhesive 4 is made of PU glue, and the base fabric of the waterproof layer is woven from 40D polyester yarn. The water-repellent effect of the waterproof layer reaches more than 90 points. The nylon fabric layer is composed of multiple uniformly distributed double-layer non-quilted nylon fabric bile ducts, the plurality of bile ducts are arranged in parallel, and the sides of two adjacent bile ducts are connected at the connection point 6 .

[0048] In this embodiment, the method for preparing the heat-storing waterproof and moisture-permeable outdoor down cold-proof clothing fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com