An outrigger mechanism for engineering vehicles and a bridge inspection vehicle

A technology for engineering vehicles and outriggers, which is applied in the field of outrigger mechanisms for engineering vehicles and bridge inspection vehicles, and can solve problems such as excessive force at the hinge point between the outrigger and the frame, cracking and damage to structural parts at the hinge, and high requirements for the stroke of the oil cylinder. , to achieve the effect of reducing the stroke amount, increasing the stress point and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

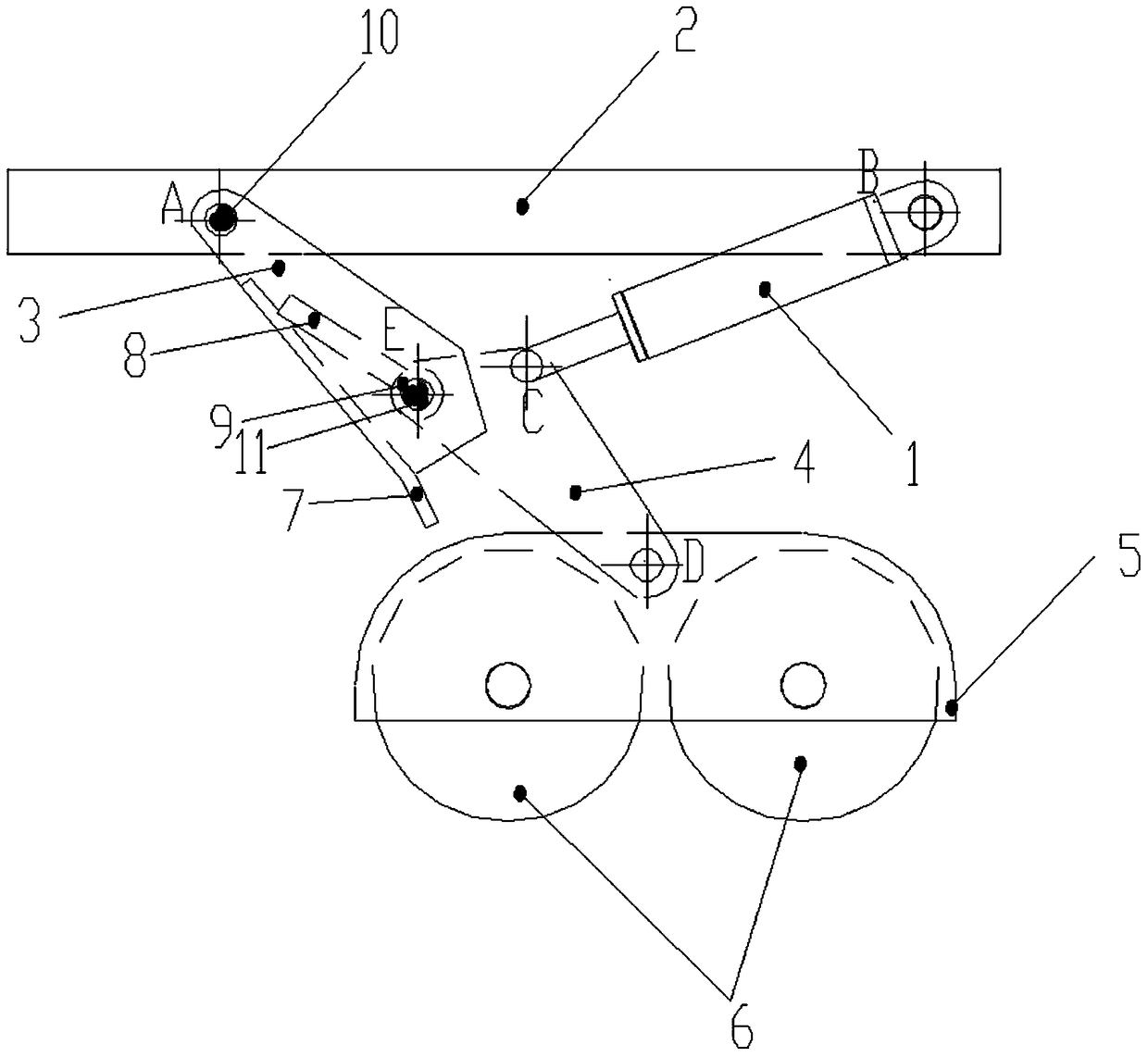

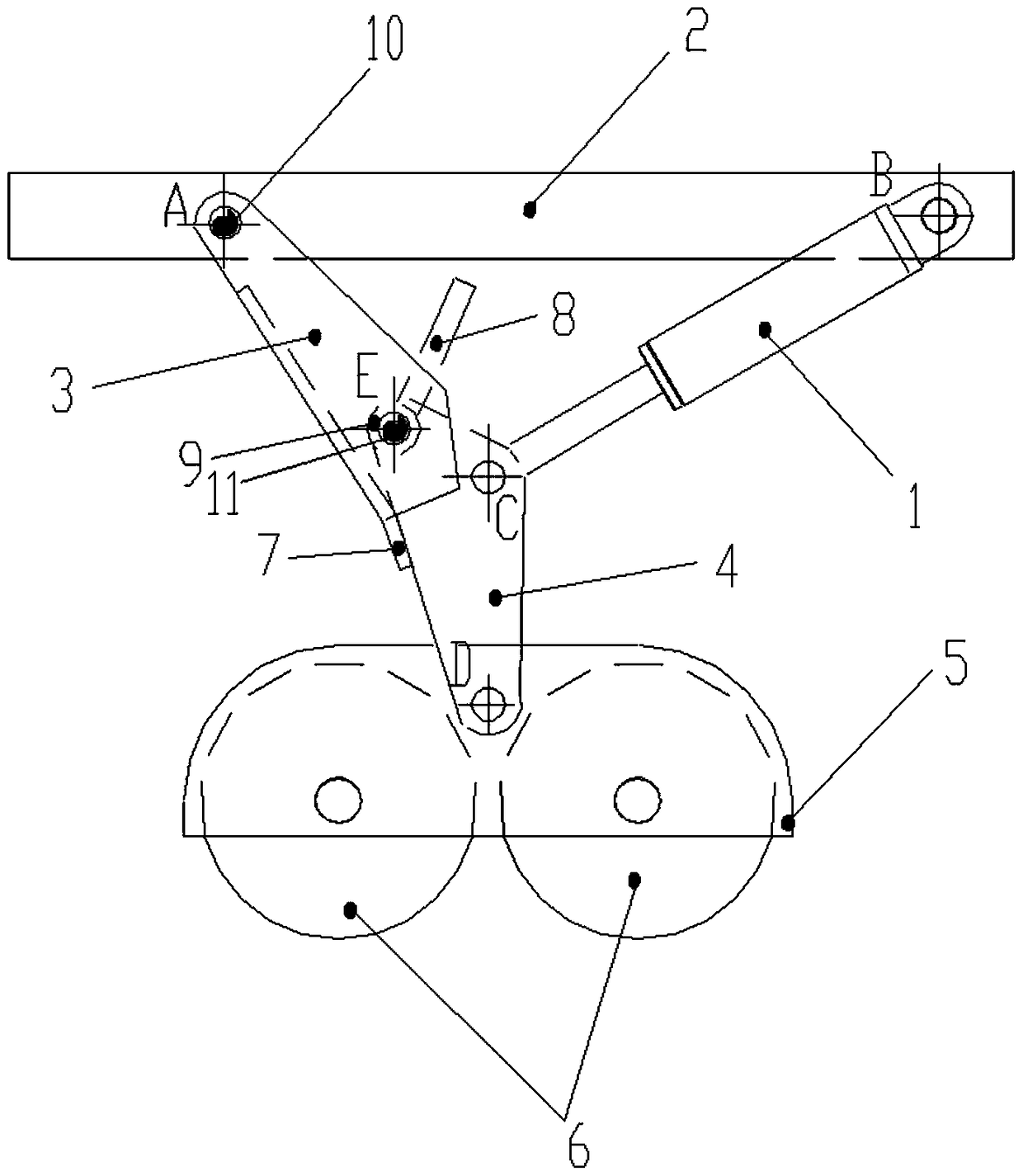

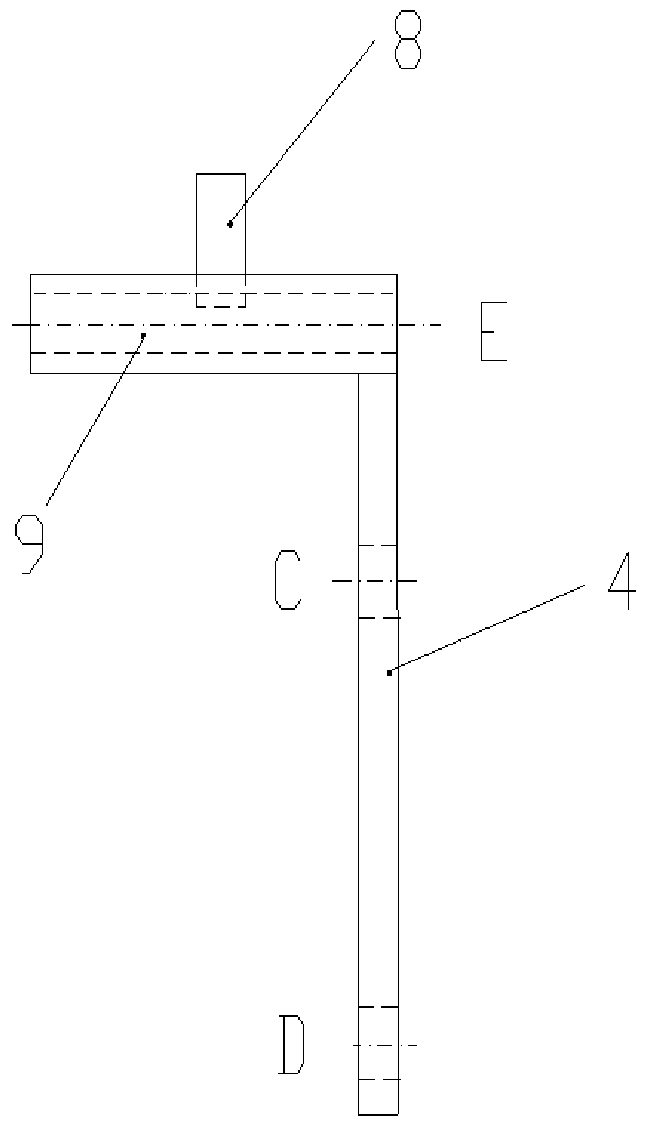

[0020] like figure 1 and 2 As shown, the outrigger mechanism for an engineering vehicle of the present invention includes an upper leg 3, a lower leg 4 and a telescopic oil cylinder 1, and the first ends of the upper leg 3 and the telescopic oil cylinder 1 are respectively connected with the vehicle frame 2 of the engineering vehicle through the first end One hinge point A is hinged to the second hinge point B, and the upper leg 3 and the second end of the telescopic oil cylinder 1 are hinged to the lower leg 4 through the third hinge point E and the fourth hinge point C respectively. Due to the different positions of the hinges, from figure 1 It can be seen that the vehicle frame 2, the upper leg 3, the lower leg 4 and the telescopic oil cylinder 1 constitute a four-bar linkage mechanism.

[0021] In the above tech...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap