Automatic delivery of goods and package building method

A technology of automatic conveying and goods, applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of high labor intensity and cumbersomeness, and achieve the goal of reducing labor intensity, reducing rushing, and reducing the difficulty of on-site operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

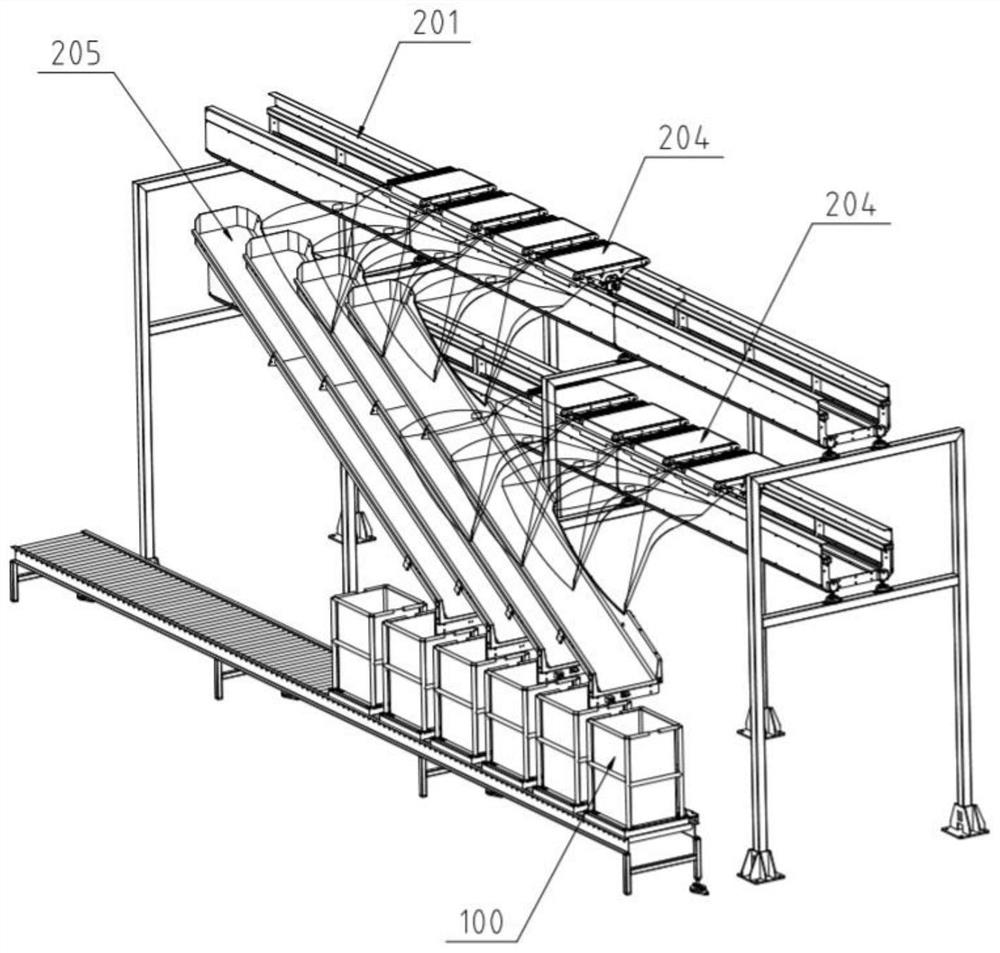

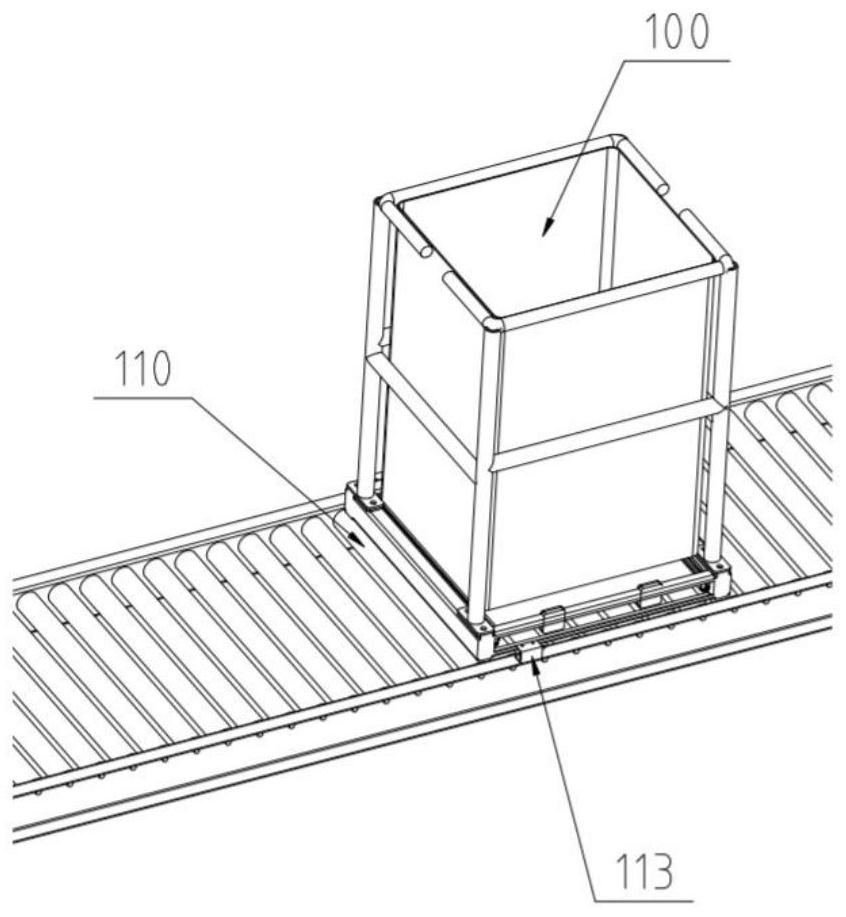

[0048] Example 1, such as figure 1 and figure 2 As shown, the automatic conveying and packaging device for goods applied in this application includes a loading area and an unloading area, a conveyor line connecting the loading area and the unloading area, and several material boxes 100 running on the conveyor line.

[0049] Wherein, the loading area has a double-layer sorting loop 201, a sorting trolley 204 that runs on the sorting loop 201 and transports goods, and a double-layer grid chute 205; The task runs to the designated grid chute 205, and then the goods are sorted into the material box 100 below through the grid chute 205.

[0050] The conveying line is a roller conveying line, and the material box 100 full of goods runs to the unloading area through the roller conveying line.

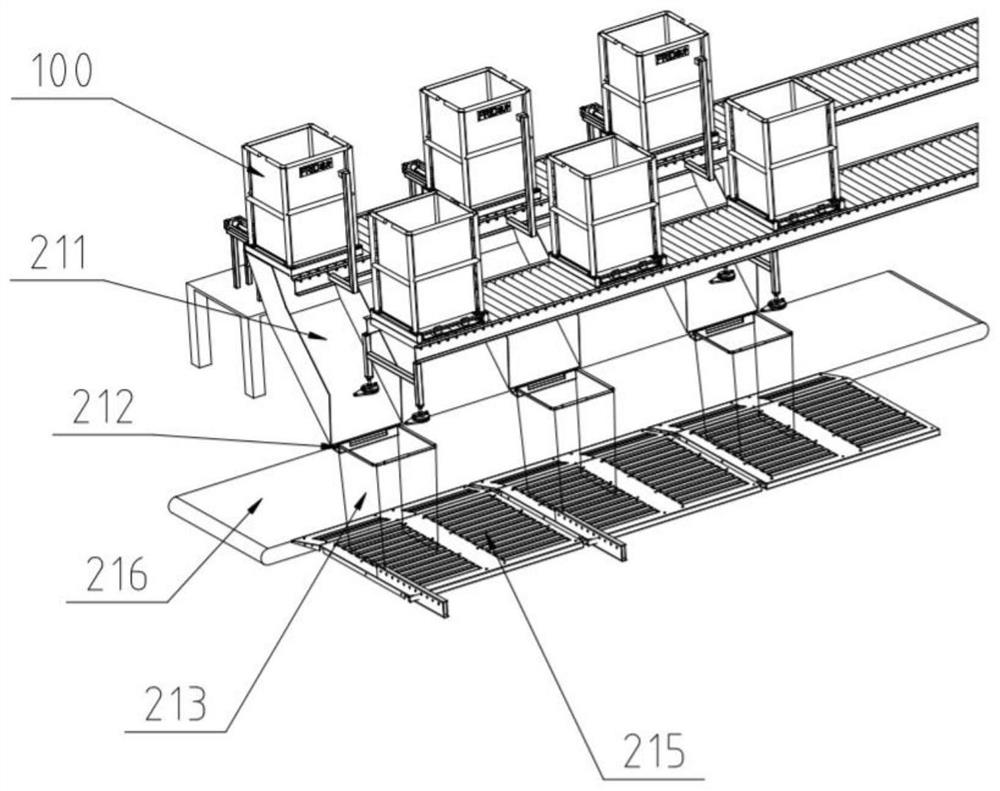

[0051] The described unloading area has a discharge chute 211 for each unloading position, a bag rack 212 and a collection bag 213 at the bottom of each discharge chute 211, and a roller ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com