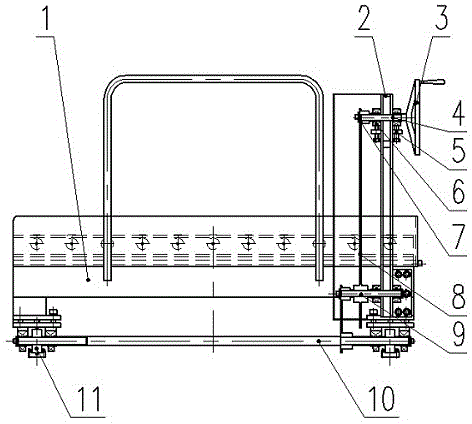

Rocking arm type mold change transmission car

A rocker type, trolley technology, applied in the directions of transportation and packaging, manual conveying devices, etc., can solve the problems of high cost, complex structure, and increased labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

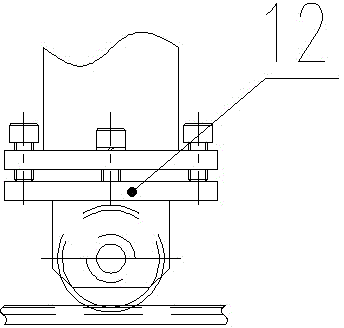

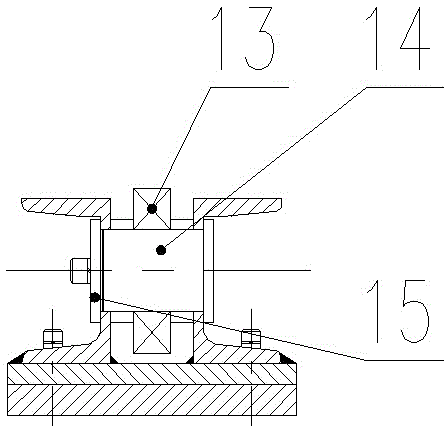

[0012] The rocker arm type mold changing transmission trolley includes trolley body 1, transmission bracket 2, hand wheel 3, transmission shaft 4, tensioning mechanism 5, bearing housing for transmission shaft 6, sprocket wheel 7, chain 8, intermediate shaft 9, Working shaft 10, wheel 11, adjusting bearing 12, feeding bearing 13, mounting shaft 14, cover plate 15, guide bearing 16, mounting shaft 17, cover plate 18. The trolley body 1 and the transmission bracket 2 are connected and fixed by screws, the transmission shaft 4 is installed on the transmission bracket 2 through the transmission shaft bearing seat 6, one end of the transmission shaft 4 is connected and fixed with the hand wheel 3, and the other end is connected and fixed with the sprocket 7. The tensioning mechanism 5 is fixed on the transmission bracket 2 and tightens the chain 8 through screws. The sprocket 7 is transmitted to the intermediate shaft 9 through the chain 8. The fixing and connection method of the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap