Solid phase extraction pressurized device

A technology of pressurizing device and solid phase extraction column, which is applied in the direction of solid adsorbent liquid separation, chemical instruments and methods, separation methods, etc., can solve the problem of inability to ensure that the liquid passing speed of solid phase extraction column is consistent and cannot be accurately controlled Problems such as liquid passing speed and affecting the convenience of experimental operation are achieved, and the effect of simple structure, accelerated experimental progress, and convenient operation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

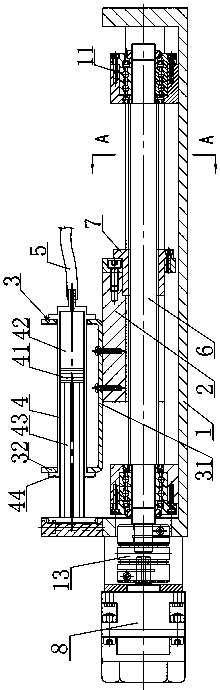

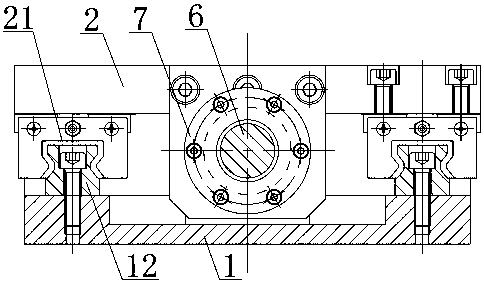

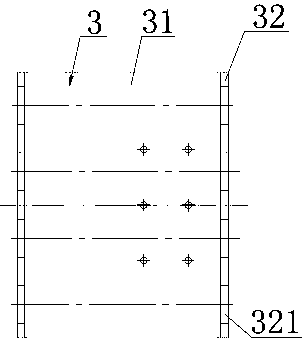

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the solid phase extraction pressurization device includes: a mounting base 1, a sliding table 2 is movable on the mounting base 1, a support 3 is fixedly installed on the sliding table 2, and several horizontal and parallel to each other are installed on the support 3. Pressurized sleeve 4. The number of pressure sleeves 4 can be specifically set according to experimental needs. In this embodiment, the structure of the support 3 includes: a support body 31, the two ends of the support body 31 are respectively provided with a support plate 32, and a plurality of card slots 321 with top openings are arranged on the support plate 32 at each end. The slots 321 on the plate 32 correspond one by one, and the two ends of each pressurizing sleeve 4 are respectively loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com