Automatic weight adding and adjusting device for fusion index meter

A technology of melt index meter and adjustment device, which is applied in the field of melt index meter and can solve problems affecting the progress of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

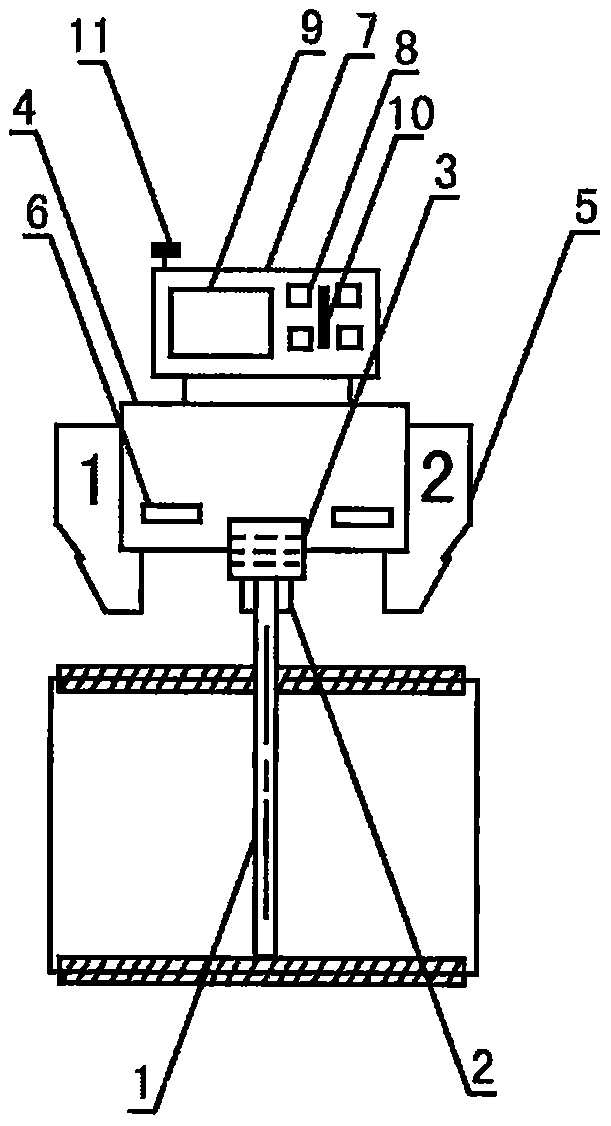

[0012] Example: as shown in the attached drawings. An automatic coding adjustment device for a melt indexer, comprising an indexer piston rod body (1), and the rod body (1) is connected with a weighting component through a bracket structure (2), comprising a display device (3), a pressure cavity (4), two an air pressure regulator (5), an air pressure sensing module (6), the control panel (7) is located on the upper surface of the cavity, and is provided with an input device (8), a code-to-digital converter (9), and a peeling device (10). When connected with the piston rod, the load operation is carried out by regularly adjusting the internal air pressure state according to the test requirements, and the display device (3) displays the weight level.

[0013] An automatic weighting adjustment device for a melt index meter is provided with a prompting device (11), and a corresponding prompting message is issued when the added weight reaches the set weight level.

[0014] An auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com