Novel cone crusher

A cone crusher and a new type of technology, applied in the field of ore crushing, can solve the problems of ejecting the crusher and danger to operators, and achieve the effect of ensuring safety, expanding the shielding area, and opening and closing smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

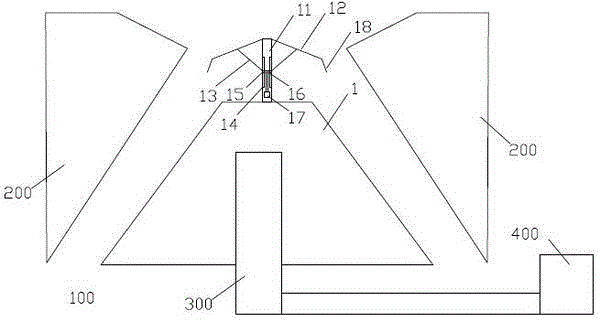

[0023] A new type of cone crusher includes a movable cone 100, a static cone 200 is arranged outside the movable cone 100, an eccentric bushing 300 is sleeved inside the movable cone 100, and the eccentric bushing 300 passes through a transmission device Connected with the motor 400; the moving cone 100 includes a moving cone main body 1, the middle part of the moving cone main body 1 is provided with a connecting column 11, and the top of the connecting column 11 is provided with a shelter 12, and inside the shelter 12 The side is provided with a guide bar 13, and the outer surface of the connecting column 11 is provided with a vertical guide groove 14. One end of the guide bar 13 is located in the guide groove 14, and one end of the drive guide bar 13 is also provided in the guide groove 14. The guide block 15 that moves up and down. When the ore falls from the top of the cone crusher to the upper part of the movable cone main body 1, the movable cone main body 1 will first ...

Embodiment 2

[0025] A new type of cone crusher includes a movable cone 100, a static cone 200 is arranged outside the movable cone 100, an eccentric bushing 300 is sleeved inside the movable cone 100, and the eccentric bushing 300 passes through a transmission device Connected with the motor 400; the moving cone 100 includes a moving cone main body 1, the middle part of the moving cone main body 1 is provided with a connecting column 11, and the top of the connecting column 11 is provided with a shelter 12, and inside the shelter 12 The side is provided with a guide bar 13, and the outer surface of the connecting column 11 is provided with a vertical guide groove 14. One end of the guide bar 13 is located in the guide groove 14, and one end of the drive guide bar 13 is also provided in the guide groove 14. The guide block 15 that moves up and down.

[0026] There are multiple guide strips 13 and multiple guide grooves 14 , and the number of guide strips 13 is the same as the number of guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com