All Terrain Vehicle Pneumatic Tires

A technology for pneumatic tires and all-terrain vehicles, which is applied to tire parts, tire treads/tread patterns, vehicle components, etc., and can solve problems such as circumferential ground jump, tire yaw, and impact on vehicle comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

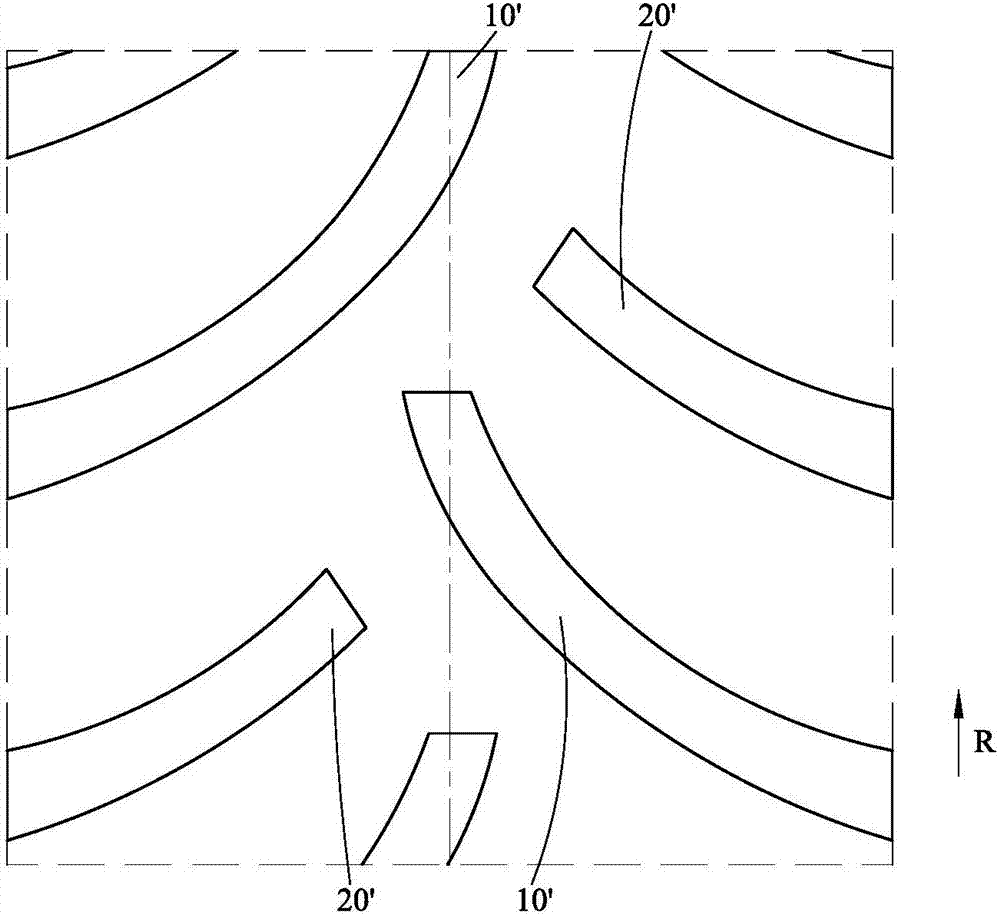

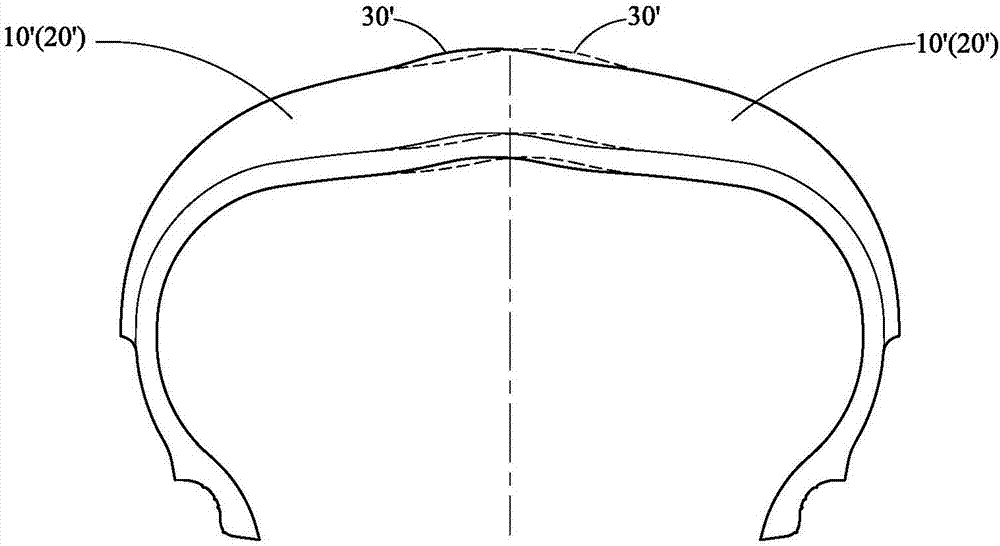

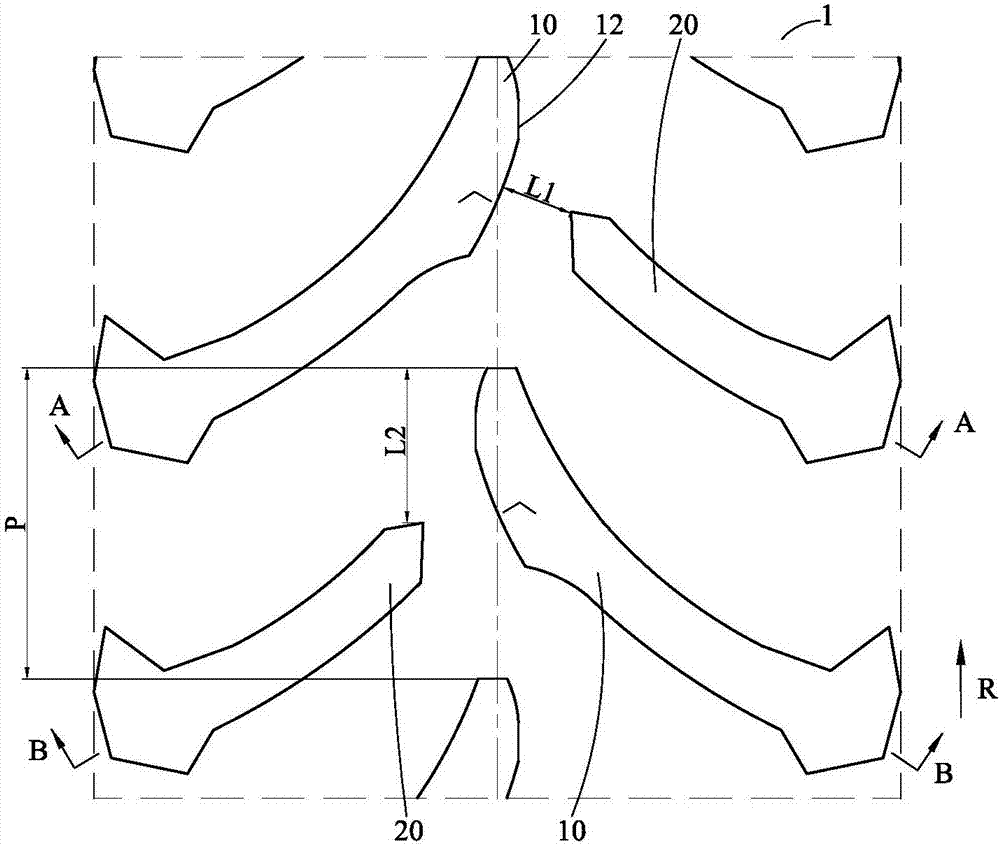

[0025] Such as image 3 , 4 As shown, the present invention discloses a pneumatic tire for all-terrain vehicles used on off-road roads. The tire tread 1 is composed of several pattern units uniformly distributed along the tire circumferential direction. Symmetrical and alternately arranged main pattern blocks 10 and auxiliary pattern blocks 20, each set of main pattern blocks 10 and auxiliary pattern blocks 20 extend from the center of the tread to the shoulders on both sides, and the main pattern blocks 10 near the center of the tread The head crosses the center plane of the tread, and there is a distance between the head of the auxiliary pattern block 20 close to the main pattern block 10 and the main pattern block 10; the key points of the present invention are:

[0026] The cross-sectional profile structure of each set of main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com