Beer keg valve

The technology of a wine spear and a wine pipe is applied in the field of wine drinking equipment, which can solve the problems of laborious operation of wine, poor operation feel, large friction, etc., and achieve the effect of easy operation of wine, ensuring stability and ensuring sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

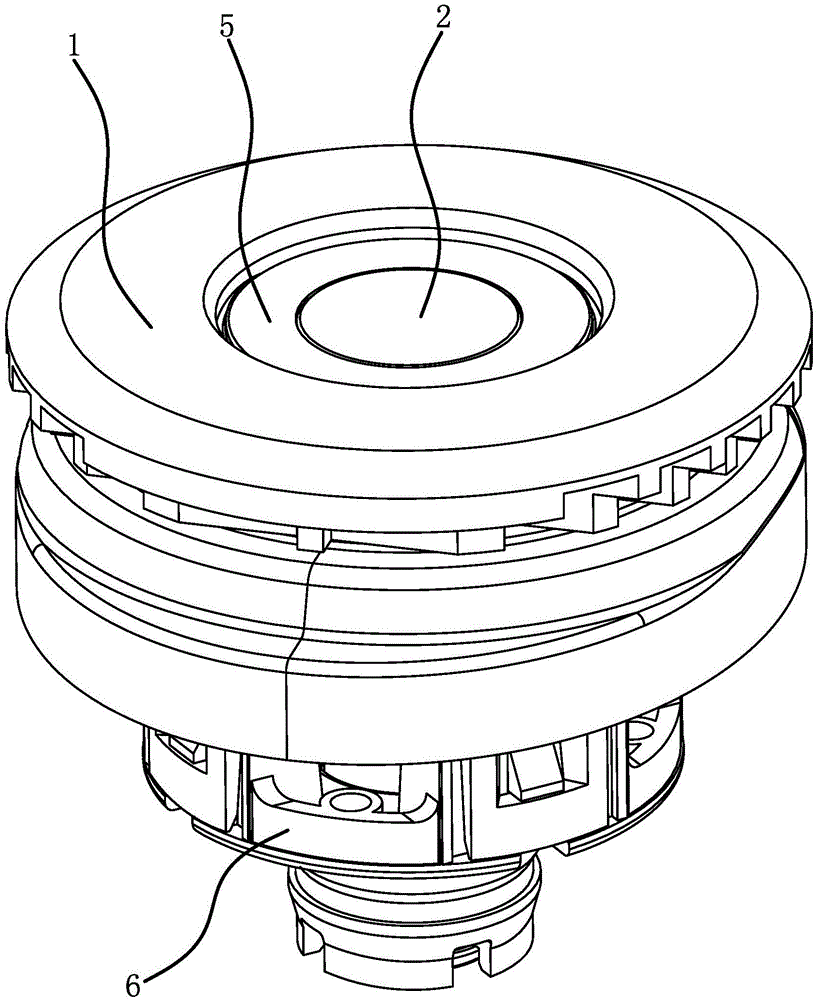

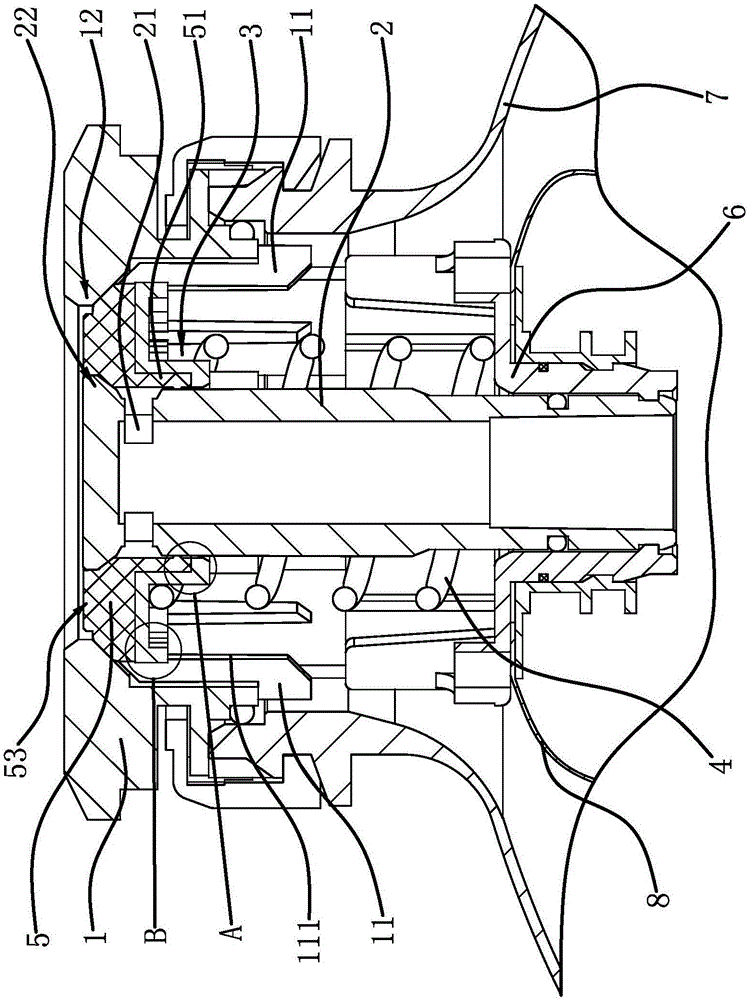

[0035] Such as figure 1 , figure 2 , image 3 As shown, a wine spear, the wine spear is used in conjunction with the barrel body 7 to form a wine barrel, the wine spear includes a valve body 1, a wine outlet pipe 2 with a wine outlet 21 on the side wall at the upper end, and an annular seat body 3, The lower end of the valve body 1 is fixedly connected with the bottom frame 6, the wine outlet pipe 2 passes through the bottom frame 6 and is fixedly connected with the bottom frame 6, a flexible bag 8 is fixedly connected to the wine outlet pipe 2, and the flexible bag 8 is located on the barrel body 7 Inside, used to hold wine, the wine outlet pipe 2 extends into the flexible bag 8, the seat body 3 is slidably sleeved on the upper end of the wine outlet pipe 2, and the seat body 3 is located in the valve body 1, between the valve body 1 and the seat body 3 There is a return spring 4 that can make the seat body 3 and the inner wall of the valve body 1 lean against. Pressed on...

Embodiment 2

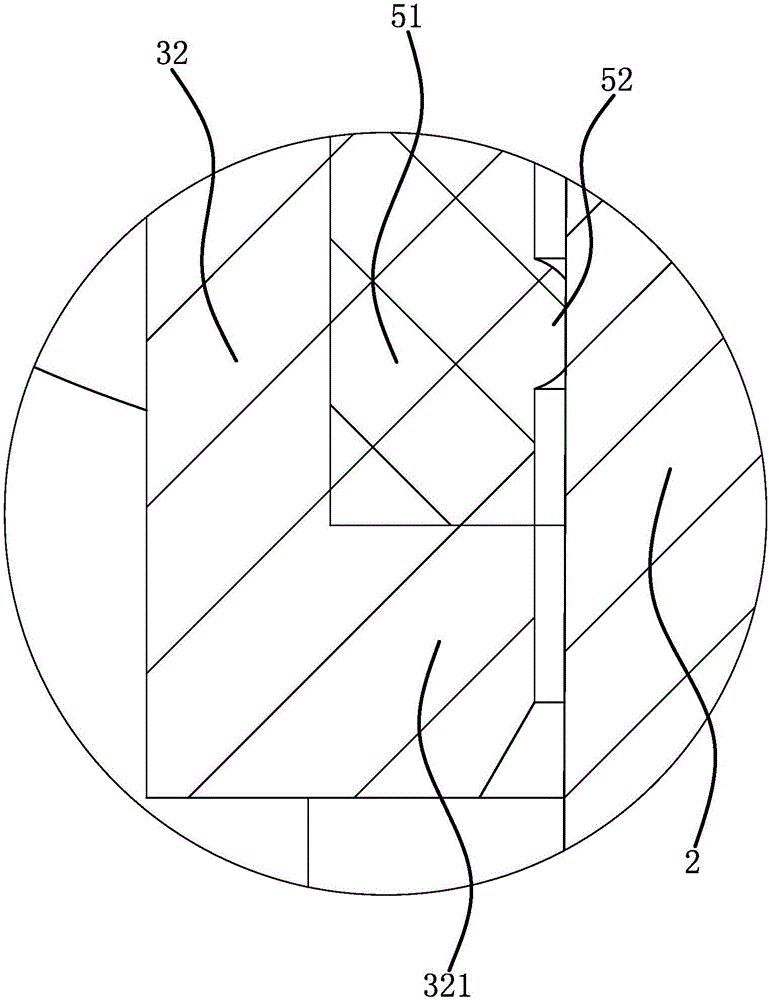

[0041] The structure of the wine spear is basically the same as in Embodiment 1, the difference is that Figure 9 , Figure 10 As shown, the inner wall of the seat body 3 is provided with a sealing groove 322 in the circumferential direction, the sealing ring 52 is arranged in the sealing groove 322, and the inner ring of the sealing ring 52 protrudes from the notch of the sealing groove 322 and presses against the outer wall of the wine outlet pipe 2, This structure does not provide a sealing layer 51 on the inner wall of the seat body 3, but directly sleeves a sealing ring 52, which has a simple structure and can have better sealing performance with the assistance of the guiding structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com