Baffle body for functional component with carrier element made of plastic

A technology for functional components and elements, which is applied in the field of baffle bodies for functional components with carrier elements made of plastic, can solve the problems of consuming the total manufacturing process, difficulty in manufacturing methods, inflexibility, etc., and achieves a reduction in total weight , Reduce manufacturing costs, and facilitate the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

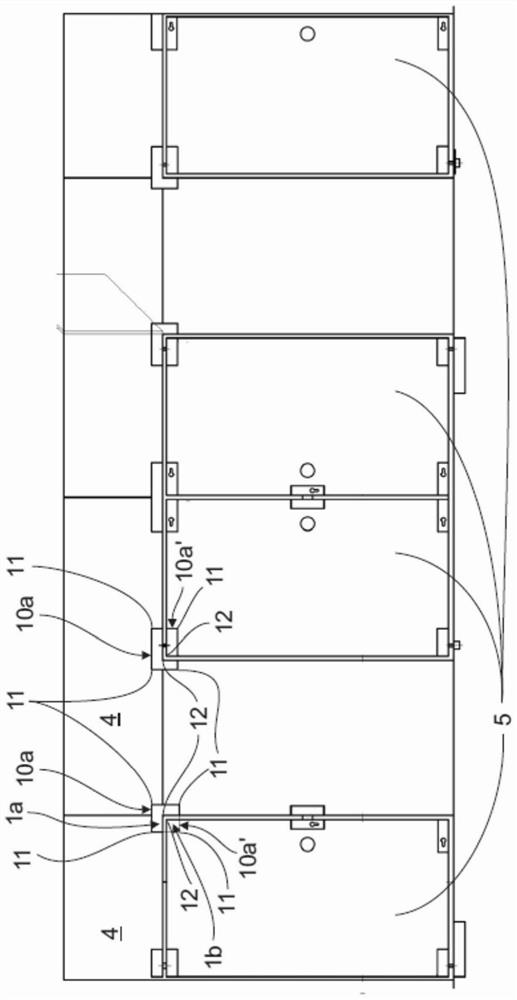

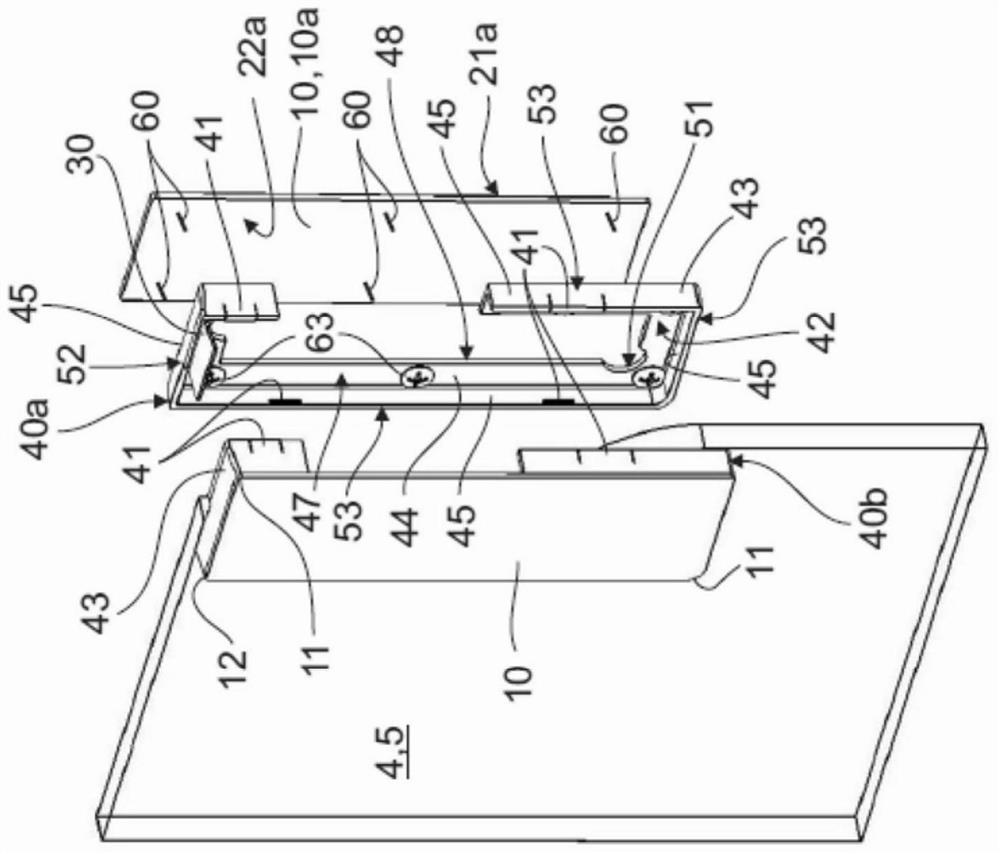

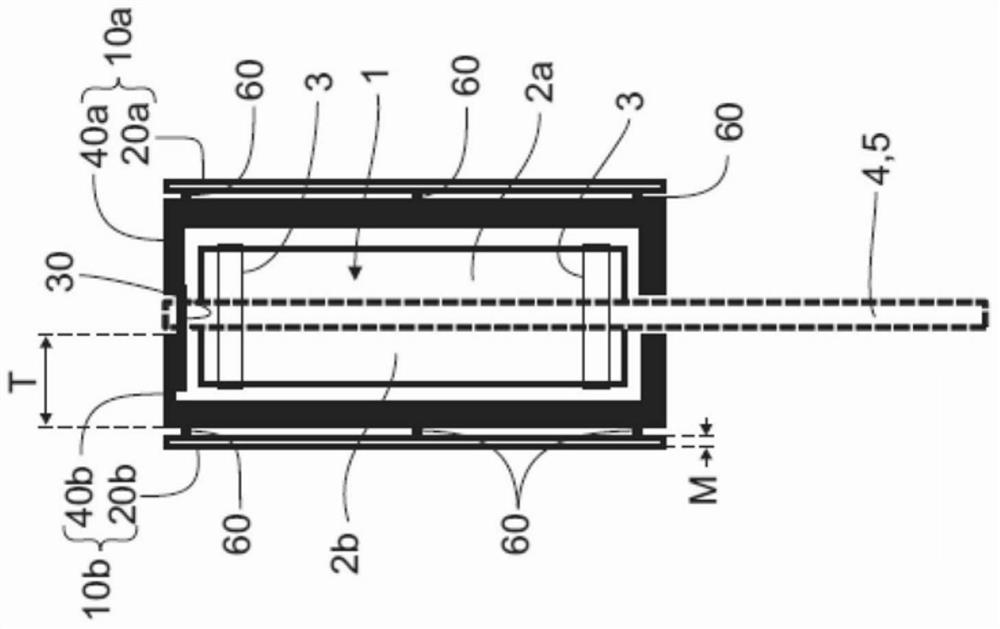

[0044] figure 1 A possible shutter arrangement is shown with a plurality of shutter bodies 10a, 10a', which cover the functional components 1a, 1b. The baffle bodies 10a, 10a' are arranged next to each other, wherein the baffle bodies 10a, 10a' are each adapted to adjacent contours. In this case, the first flap body 10 a is arranged on a first functional component, which is not shown in detail. The first component is at least partially covered by the first flap body, which will be discussed further below. Likewise, the second baffle body 10a' is arranged on another second functional component 1b, which cannot be seen in detail either. figure 1 see in. The second member 1b is partially covered by the second shutter body 10a'. The first apron body 10a and the second apron body 10a' have a plurality of corner regions 11, 12, wherein the corner region 12 of the first apron body 10a facing the second component 1b is designed as an angular corner region 12. The corner region 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com