A large-scale negative pressure heating furnace air preheating system and method

A technology for air preheating and heating furnace, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., to achieve the effect of improving energy saving efficiency, simple maintenance, and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

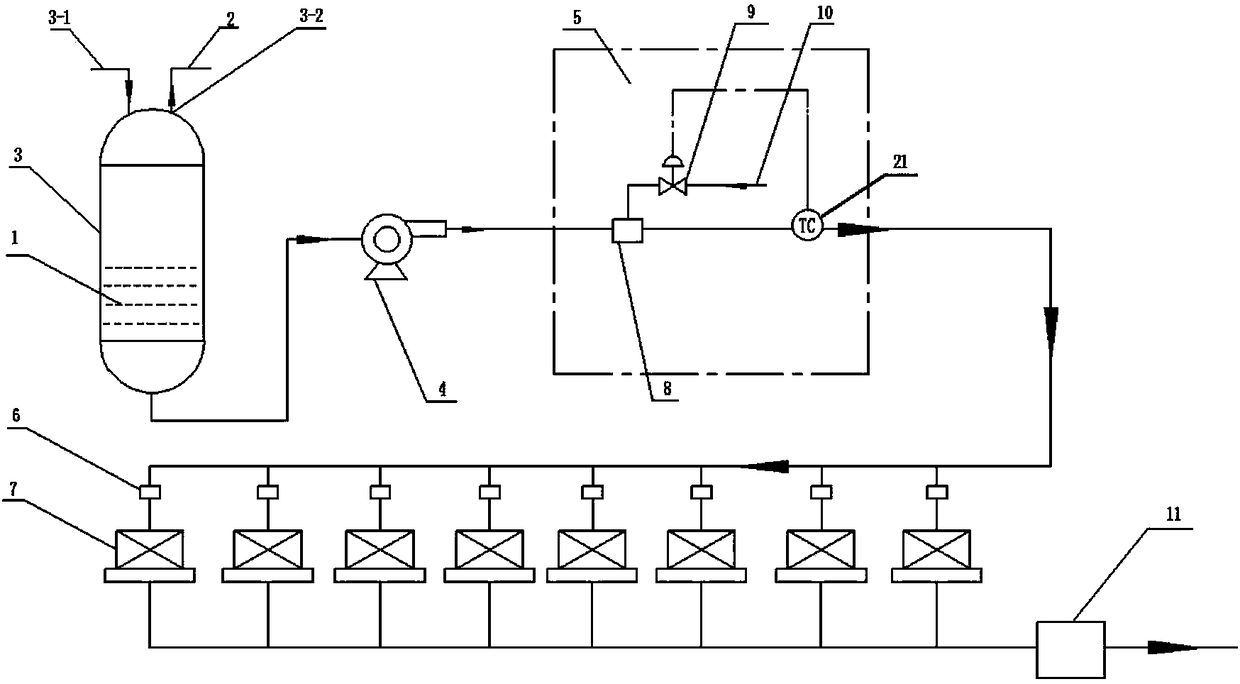

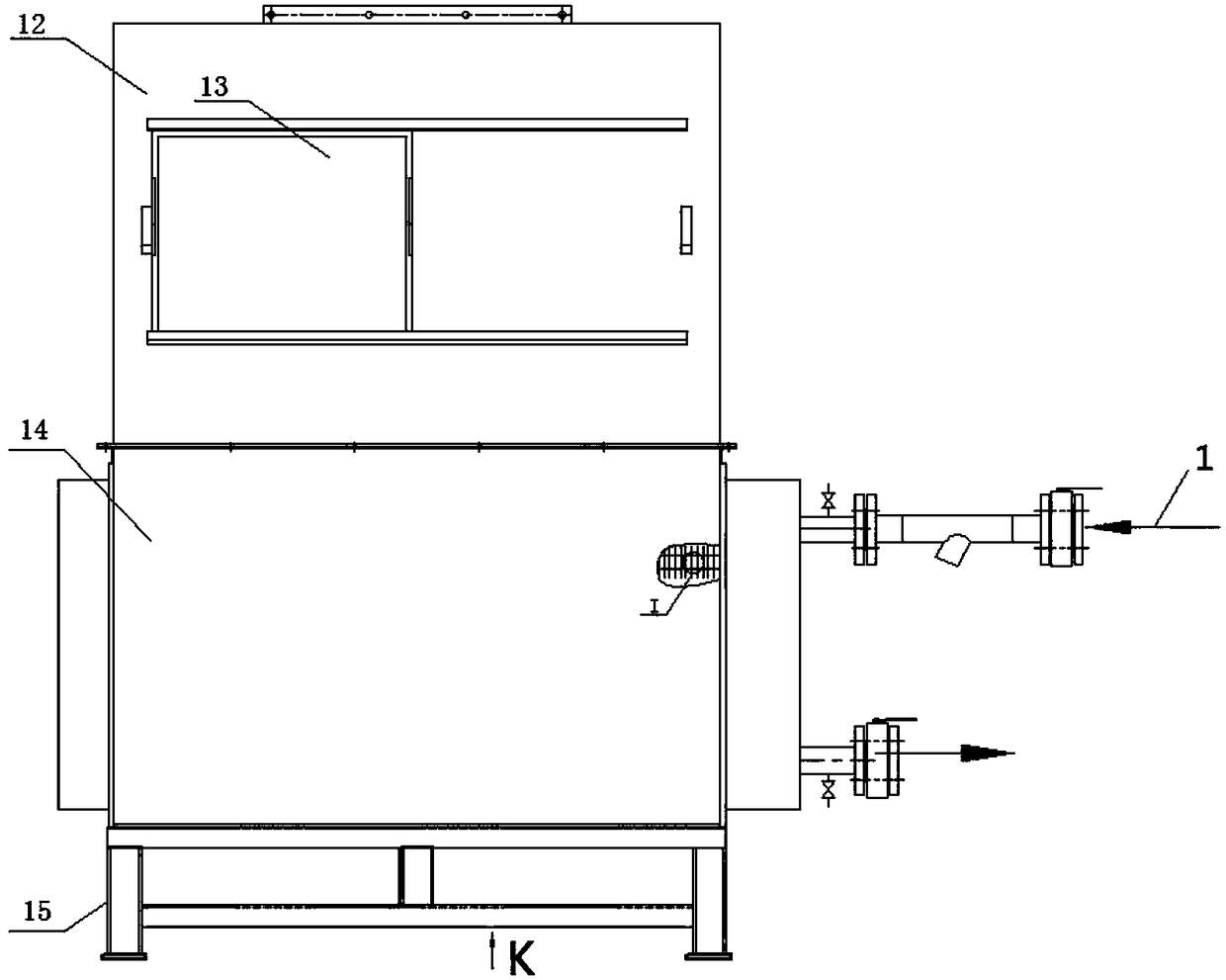

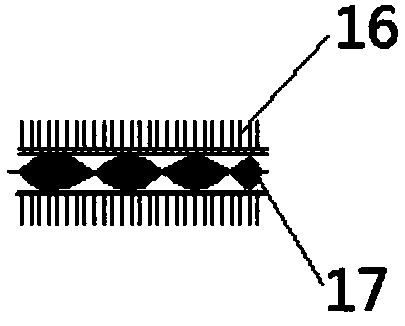

[0036] like Figures 1 to 4 As shown, a large-scale negative pressure heating furnace air preheating system includes a flash tank 3, a centrifugal pump 4, a desuperheating system 5, a preheating device and a return water system 11, and the flash tank 3 is sequentially connected with the The centrifugal pump 4, the desuperheating system 5, the preheating device and the return water system 11 are connected, and the flash tank 3 is filled with a saturated condensate 1, and the saturated condensate 1 flows through the centrifugal pump 4 and the desuperheating system in turn. The system 5, the preheating device and the return water system 11 are then sent to the downstream processing device. The top of the flash tank 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com