Patents

Literature

70results about How to "Avoid water hammer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

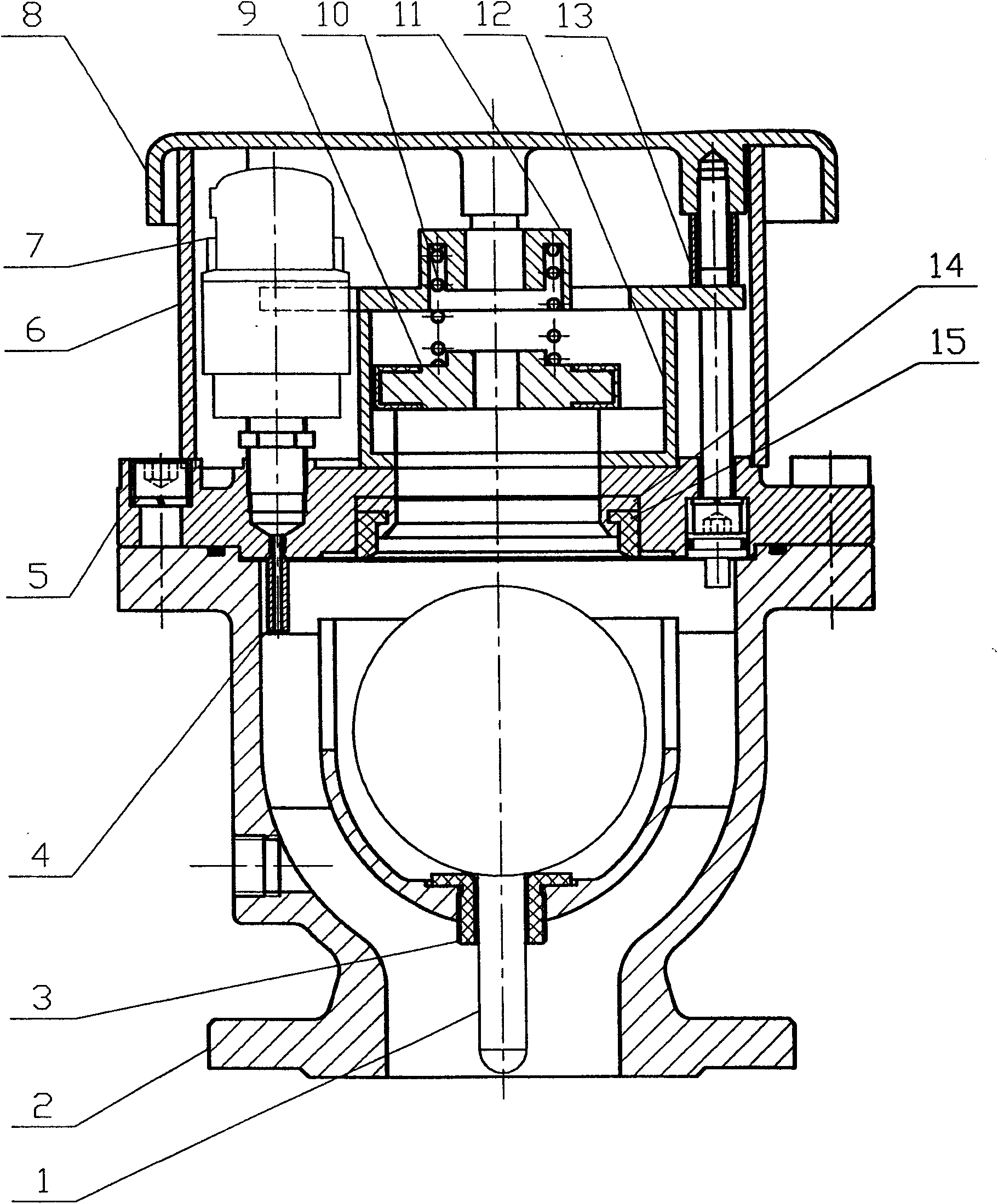

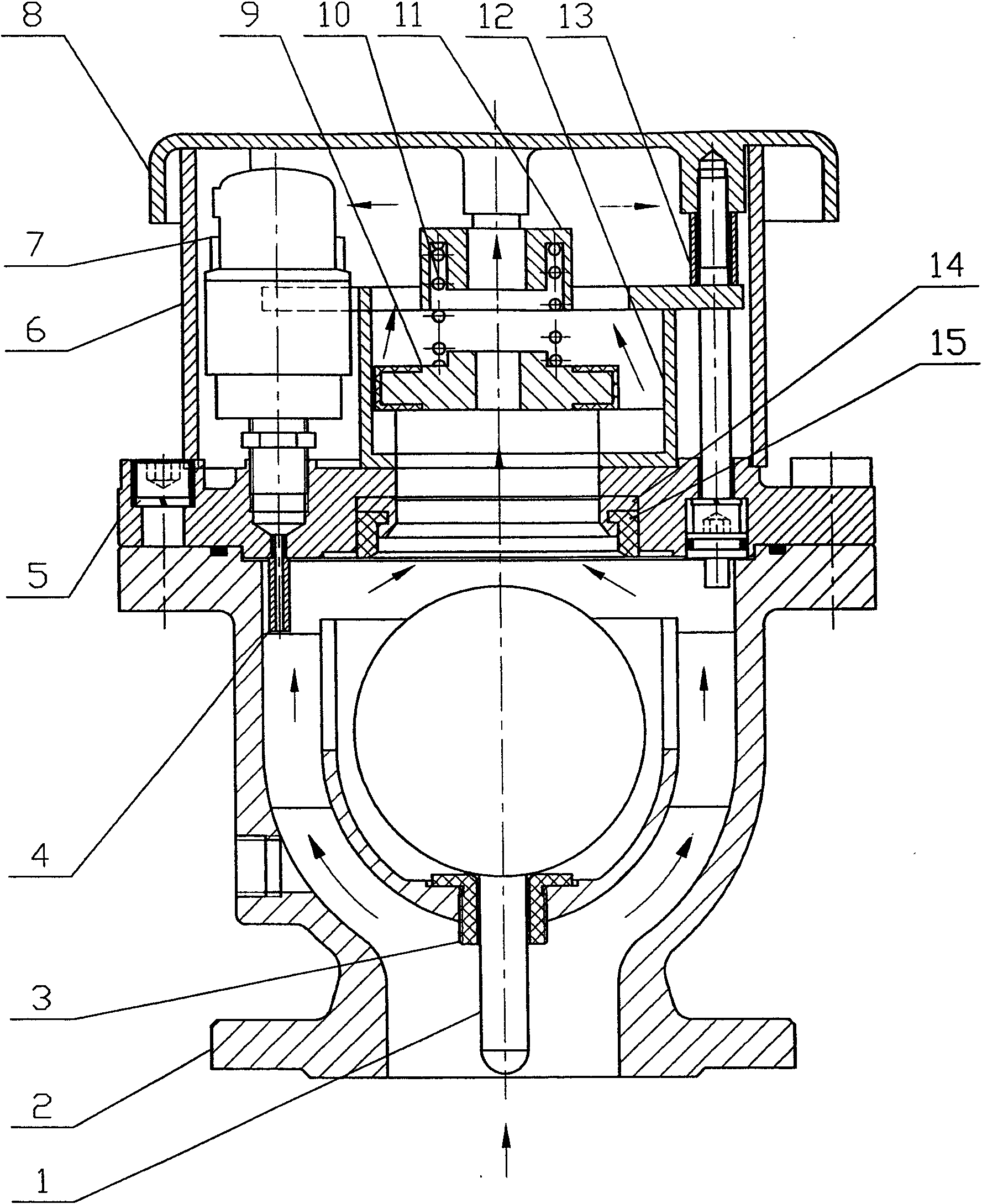

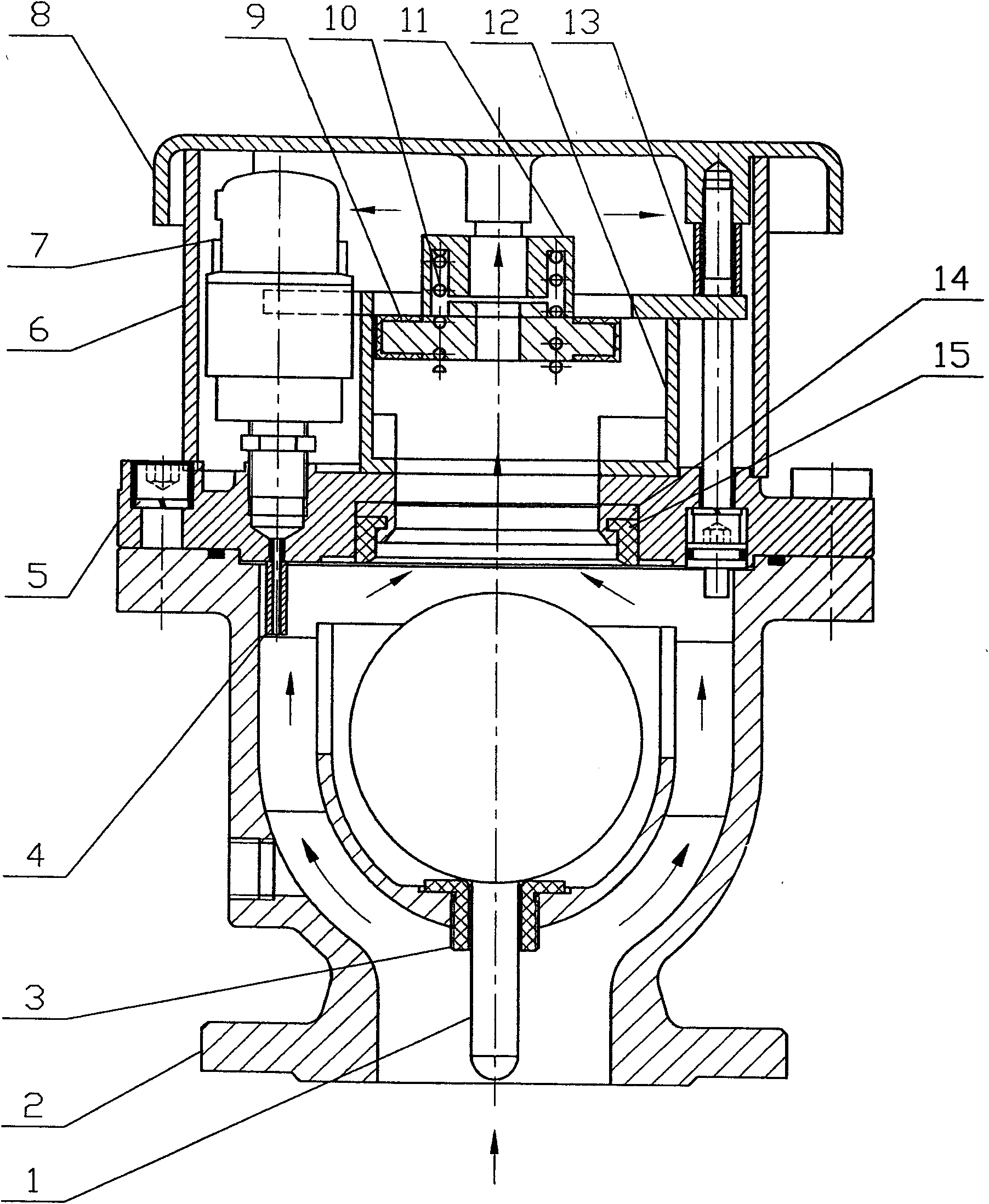

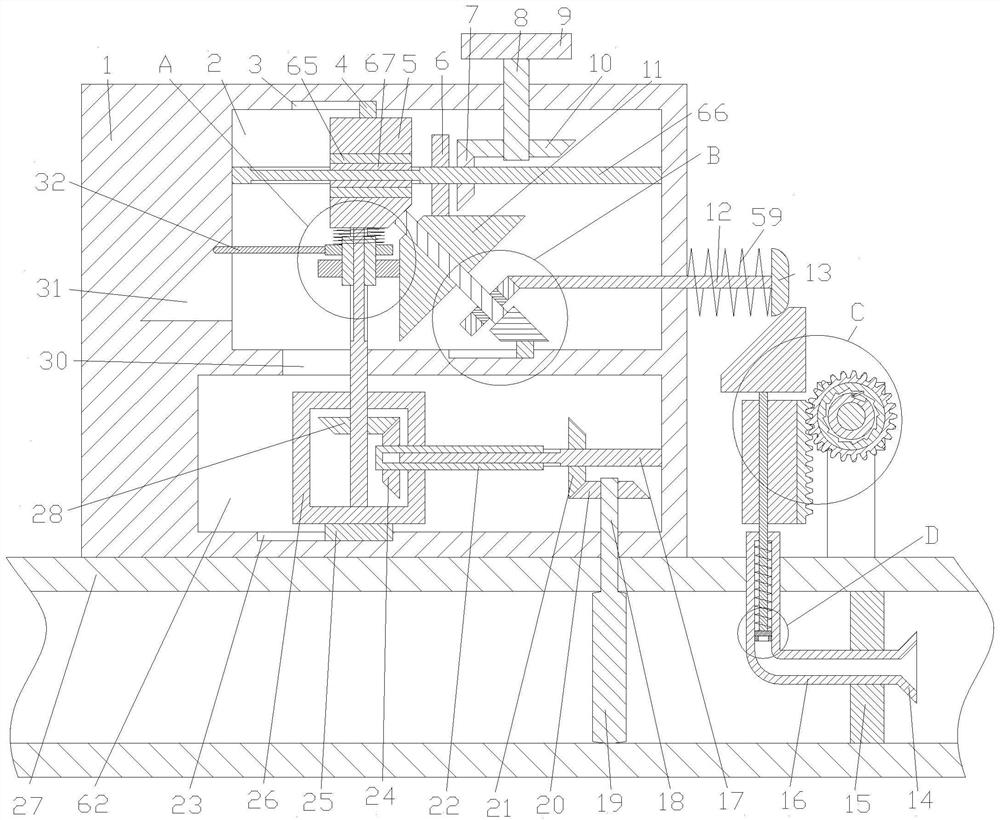

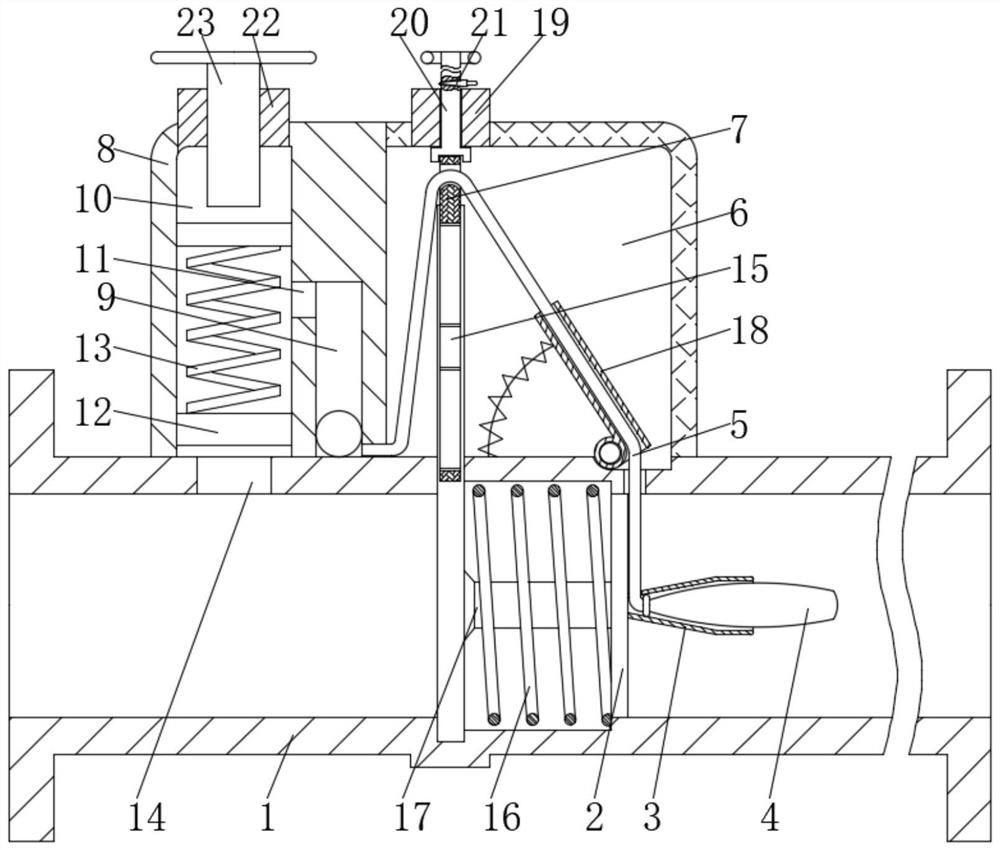

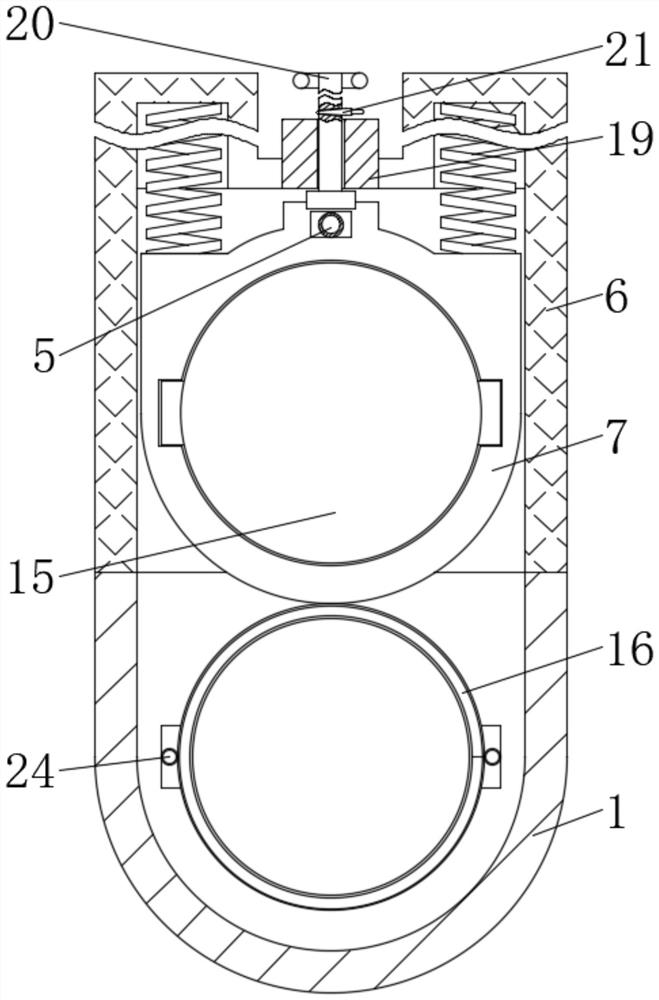

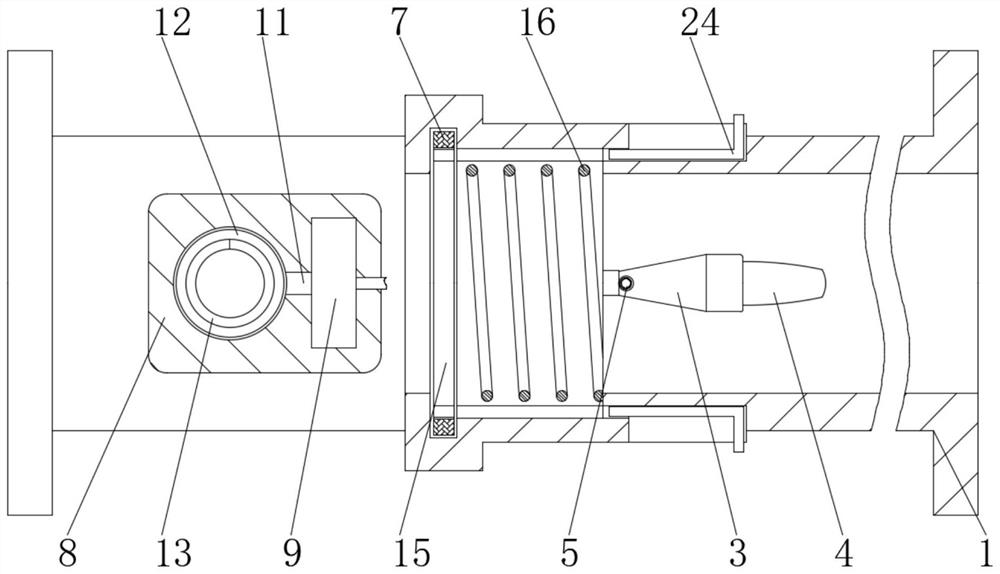

Anti-theft intelligent air release valve

ActiveCN102135186APrevent leakageAvoid water hammerOperating means/releasing devices for valvesLift valveExhaust valveEngineering

The invention provides an air intake and release valve which prevents burglary and can effectively eliminate water hammer produced when air is discharged by a water supply pipeline. The air intake and release valve comprises a mass air intake and release valve, a water hammer prevention device and a trace air intake and release valve. The trace air intake and release valve is connected with a shell of the mass air intake and release valve; the water hammer prevention device is connected with the shell of the mass air intake and release valve; and the water hammer prevention device and the trace air intake and release valve are arranged in a protective cover of the circumstance of the shell of the mass air intake and release valve. The air intake and release valve has the advantages that: the air intake and release valve with the structure can limit the air release speed when the pipeline is filled with water and releases air quickly, so that an air bag is formed in the pipeline to buffer the compact of water on the pipeline; and external parts of a valve body are effectively prevented from being stolen because the external parts are embedded in the valve body and an attachment bolt is plugged; and an air layer is reserved above a main floating ball to prevent a sealing surface from being contacted with water, eliminate the phenomenon that water is leaked due to impurity blockage, and can effectively guarantee that the sealing surface is prevented from being frozen at an extremely low temperature, the main floating ball can leave the sealing surface and vacuum is not produced in the pipeline.

Owner:TIANJIN GUOWEI FEEDING & DRAINAGE EQUIP MENT MFG

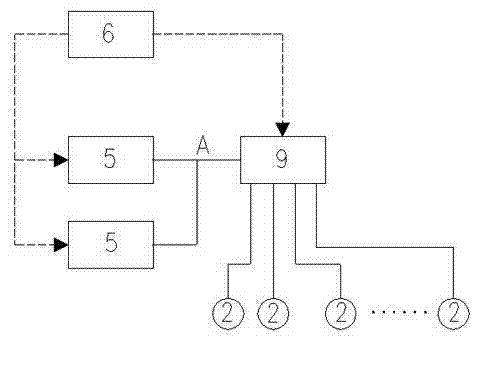

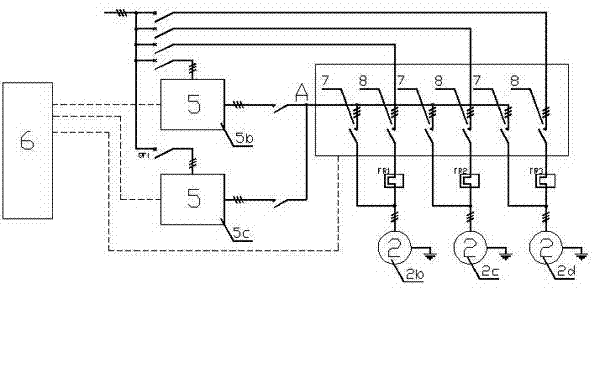

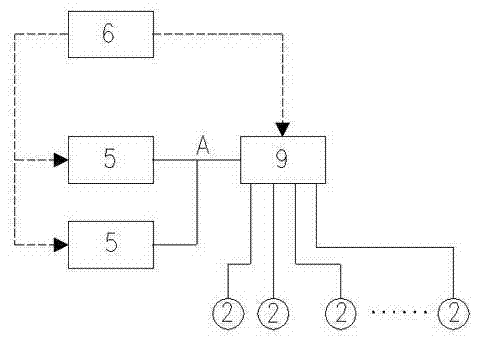

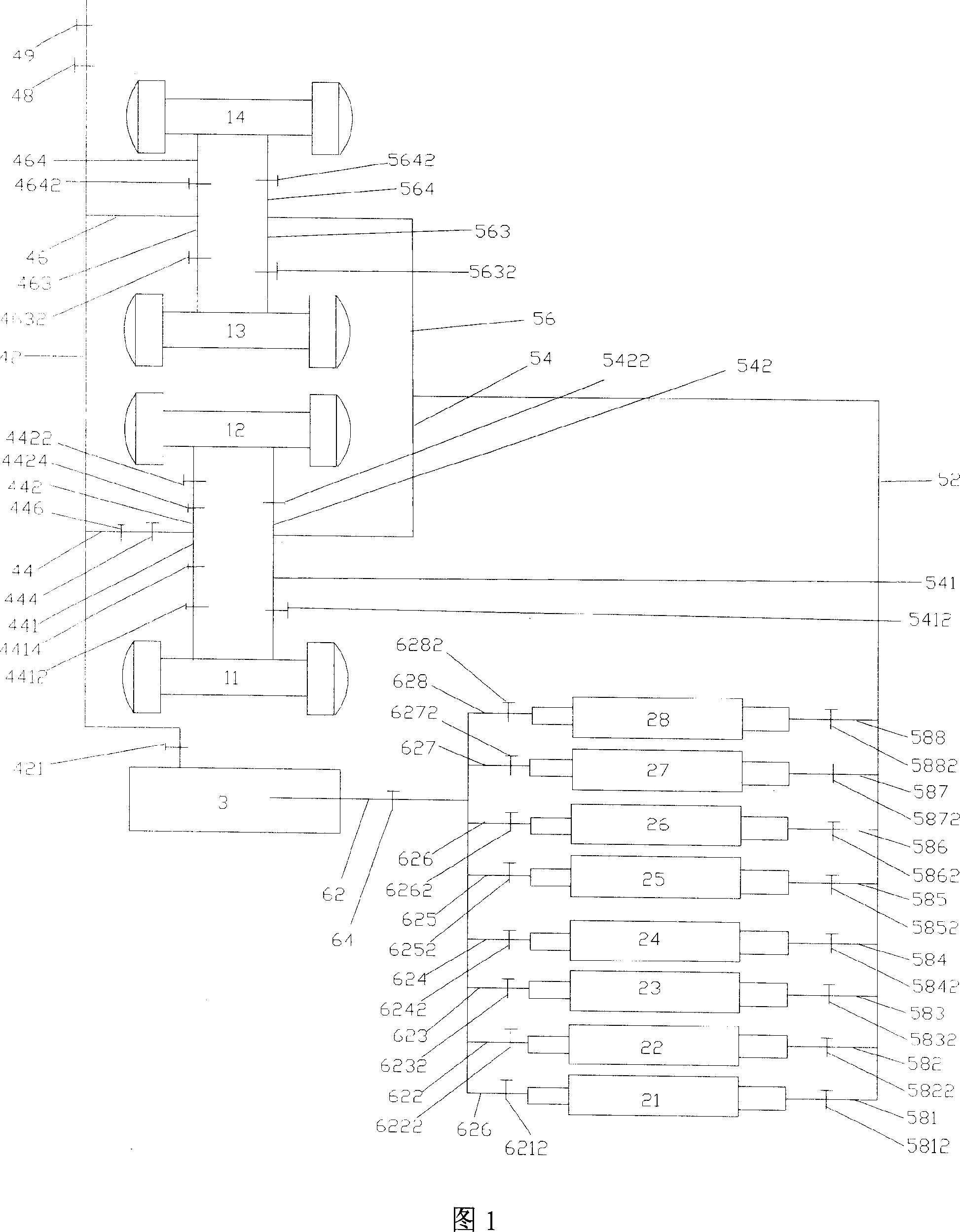

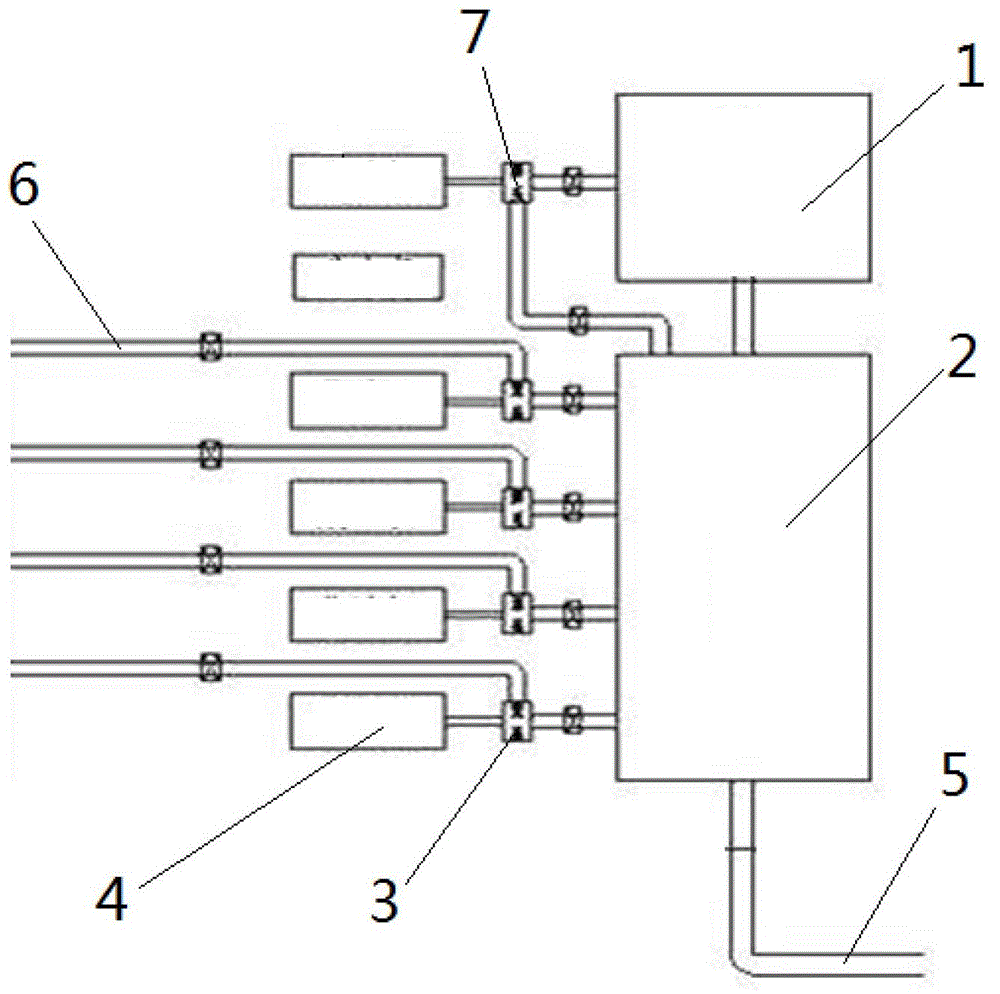

Two-control multi-constant-pressure water supply equipment control system and control method thereof

ActiveCN102359152AEliminate inrush currentAvoid water hammerService pipe systemsWater mainsFrequency changerEngineering

The invention discloses a water supply equipment control system. The system comprises a plurality of water pumps, two frequency converters, a control unit, a switching group and a water pressure sensor; the control ends of the two frequency converters are connected to the control unit, and the output ends of the two frequency converters are connected to a node A; the input end of each water pump is connected with the switching group, and the switching group is respectively connected with the control unit and the node A; the control unit controls the operation of the switching group; the switching group controls conduction or cut-off of the input ends of the water pumps and the node A; and the water pressure sensor is connected with the control unit and used for detecting the water outlet pressure of a water using point. The invention also discloses a control method of the water supply equipment control system. The system has the advantages of realizing soft start and soft stop of the water pumps, eliminating the impact current when the water pumps are started, avoiding water hammer effect, stabilizing the water supply pressure, prolonging the service life and the reliability of the equipment and better ensuring the water using safety of a user.

Owner:重庆成峰水务工程有限责任公司

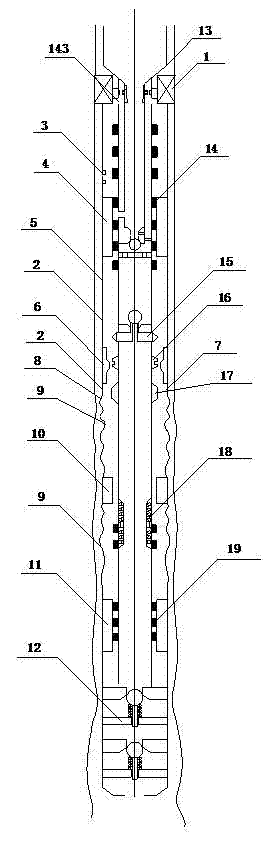

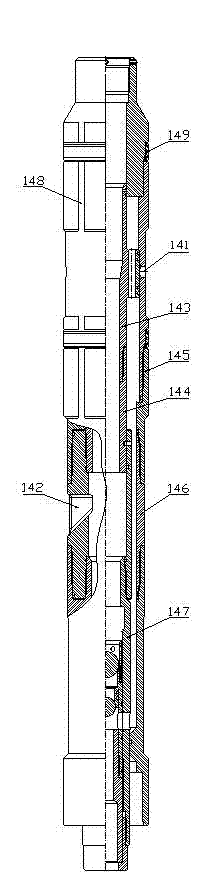

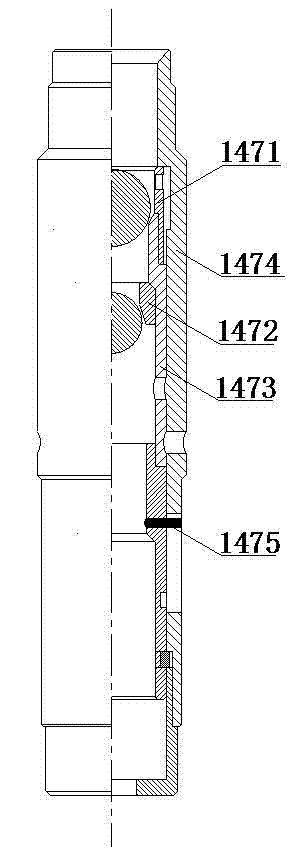

Open hole gravel packing tool and open hole gravel packing method for horizontal well

The invention discloses an open hole gravel packing tool for a horizontal well and a use method thereof. An oil layer is packed from top to bottom by adopting the open hole gravel packing tool for the horizontal well. In a packing process, a sand-carrying fluid enters through an oil pipe; specific to the aim of preventing a suction valve from being closed, the sand-carrying fluid is not allowed to flow through the suction valve, can only enter an annulus between an outer pipe column and a service tool through a packing hole of the packing tool of the service tool, and enters an open hole section oil layer through a fluid outlet hole in a packing sliding bush; and sand in the sand-carrying fluid is blocked in the oil layer through a sieve tube, the fluid enters a sand-prevention outer pipe column through the sieve tube, continually flows upwards after entering the service tool from a bottom sealed lower end hole, enters double barrels of the packing tool as well as a packing annular space formed by a central pipe and an outer layer pipe which are communicated with the double barrels, enters annuluses of a casing and the service tool through a return hole in the packing tool, and returns to the ground till packing from top to bottom is completed.

Owner:东营市瑞丰石油技术发展有限责任公司 +1

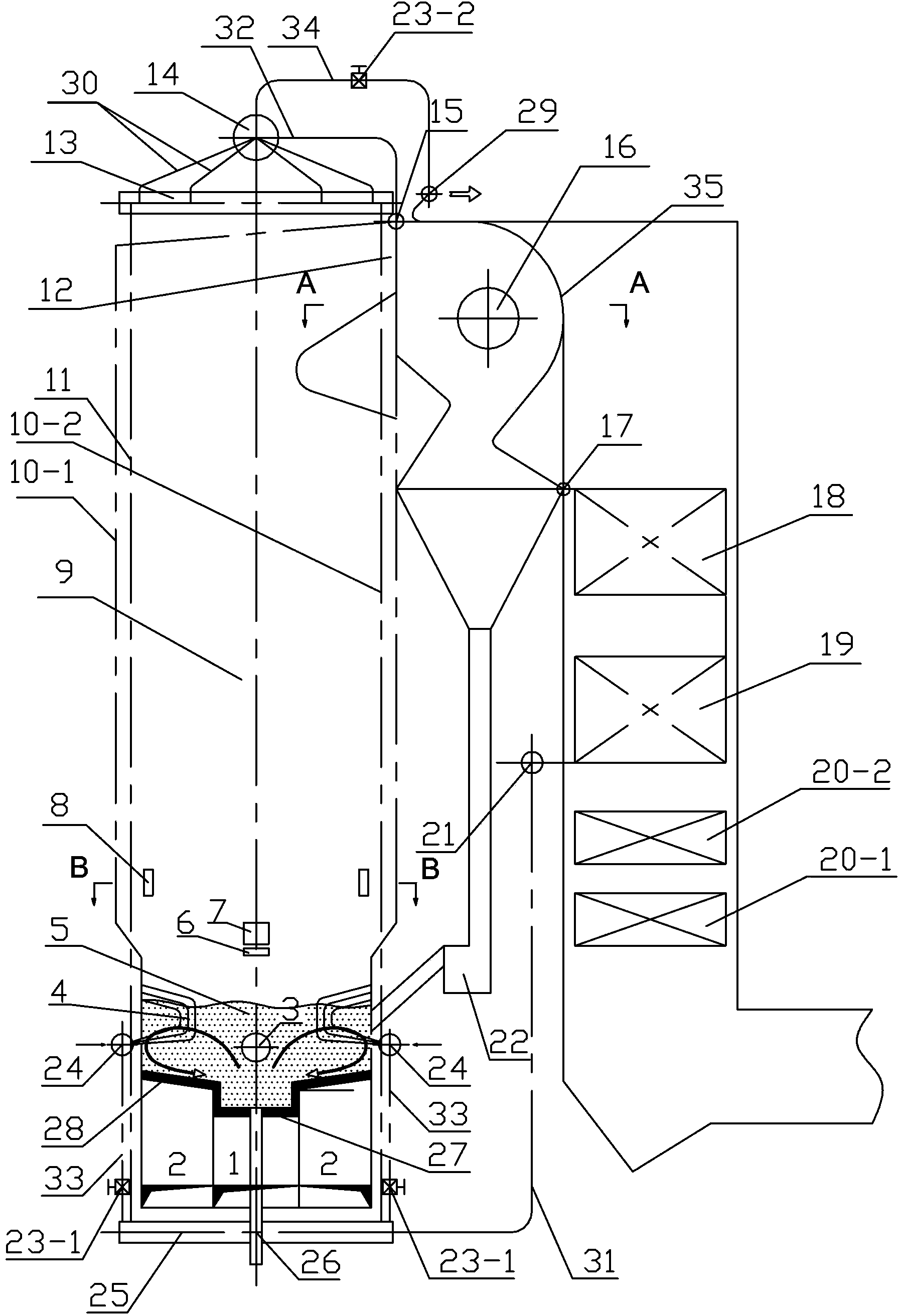

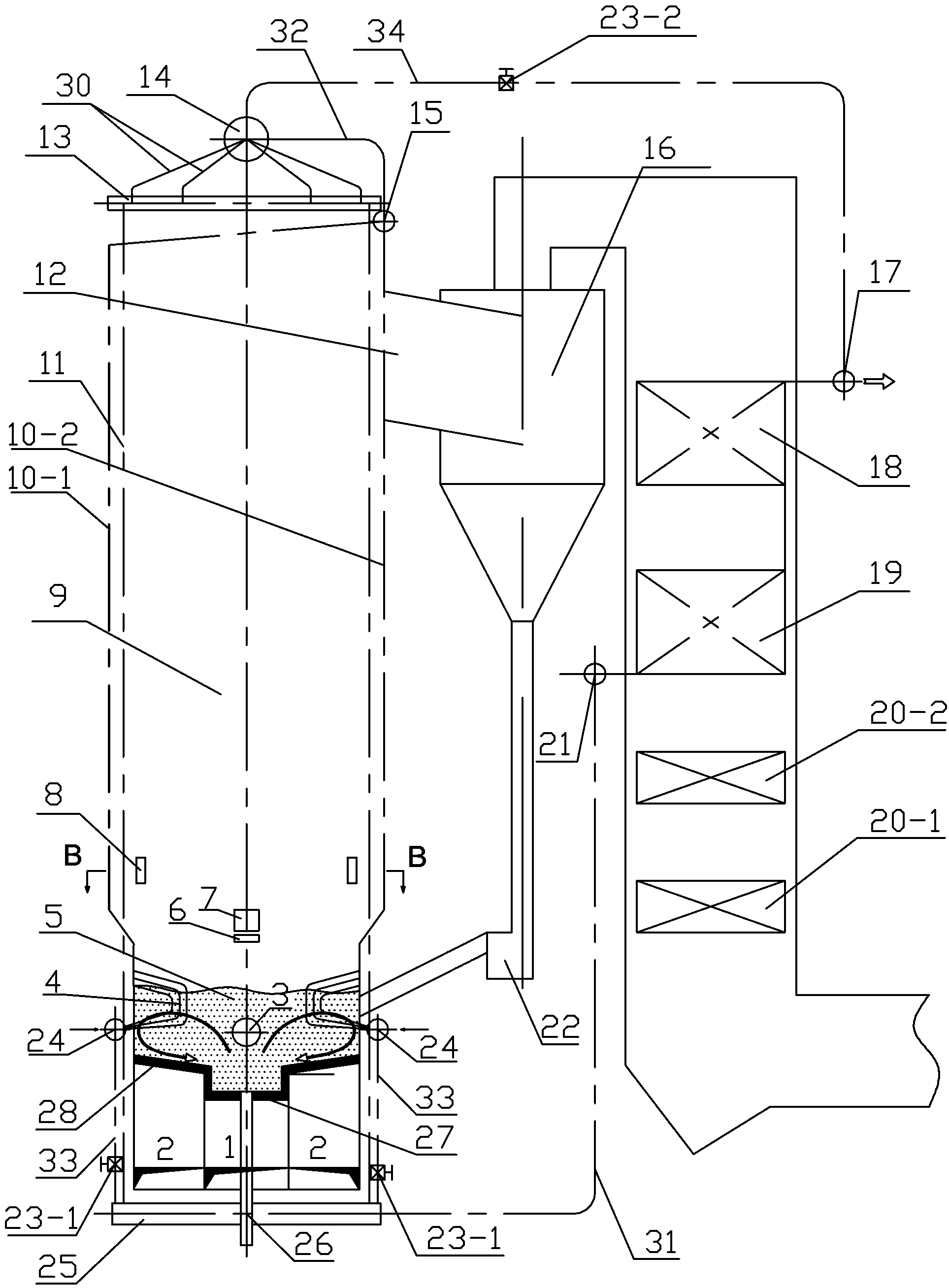

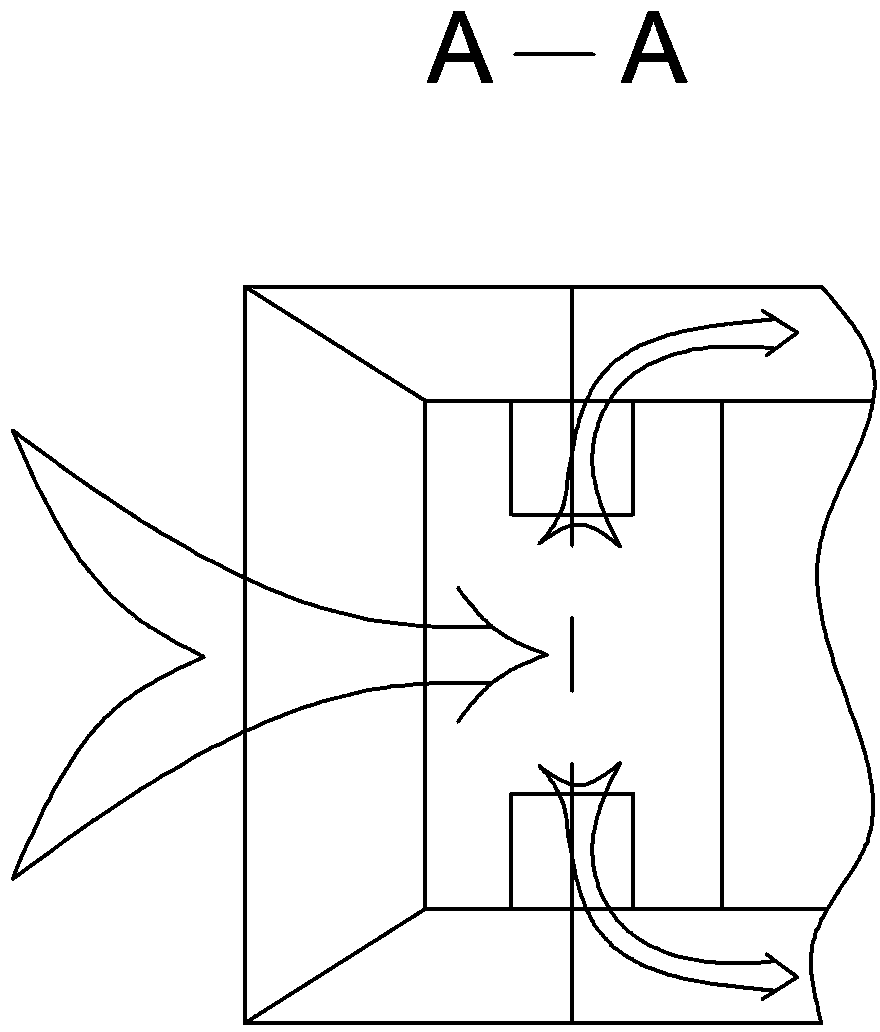

Low-range circulating fluidized bed water boiler for combusting inferior fuel and combustion method thereof

ActiveCN102901212BReduce wearReduce carbon contentFluidized bed combustionIndirect carbon-dioxide mitigationFluidized bedEngineering

The invention relates to a low-range circulating fluidized bed water boiler for combusting inferior fuel and a combustion method of the low-range circulating fluidized bed water boiler, and particularly relates to a circulating fluidized bed water boiler and a combustion method of the low-range circulating fluidized bed water boiler. The invention aims to solve the problem that the conventional grate firing water boiler can only combust high-quality coal and the water wall of the conventional circulating fluidized bed water boiler is seriously abraded when inferior fuel is combusted. Multiple buried pipes are uniformly arranged on both sides in a low-speed bed in a dense-phase area on the lower part of the boiler body; both sides of a high-speed bed air chamber are respectively provided with a low-speed bed air chamber; an intermediate wind-distribution plate is arranged at the upper part of the high-speed bed air chamber; the upper part of each low-speed bed air chamber is respectively provided with a side wind-distribution plate; a two-side wall water-cooling wall upper header is arranged at the upper end of the boiler body; a two-side wall water-cooling wall lower header is arranged at the lower end of the boiler body; a boiler barrel is arranged on the upper part of the two-side wall water-cooling wall upper header; and the two-side wall water-cooling upper header is communicated with the boiler barrel through a first connecting pipe. The low-range circulating fluidized bed water boiler for combusting inferior fuel is applied to the fields of utility boilers, industrial boilers and waste disposal utilization.

Owner:哈尔滨红旗锅炉有限公司

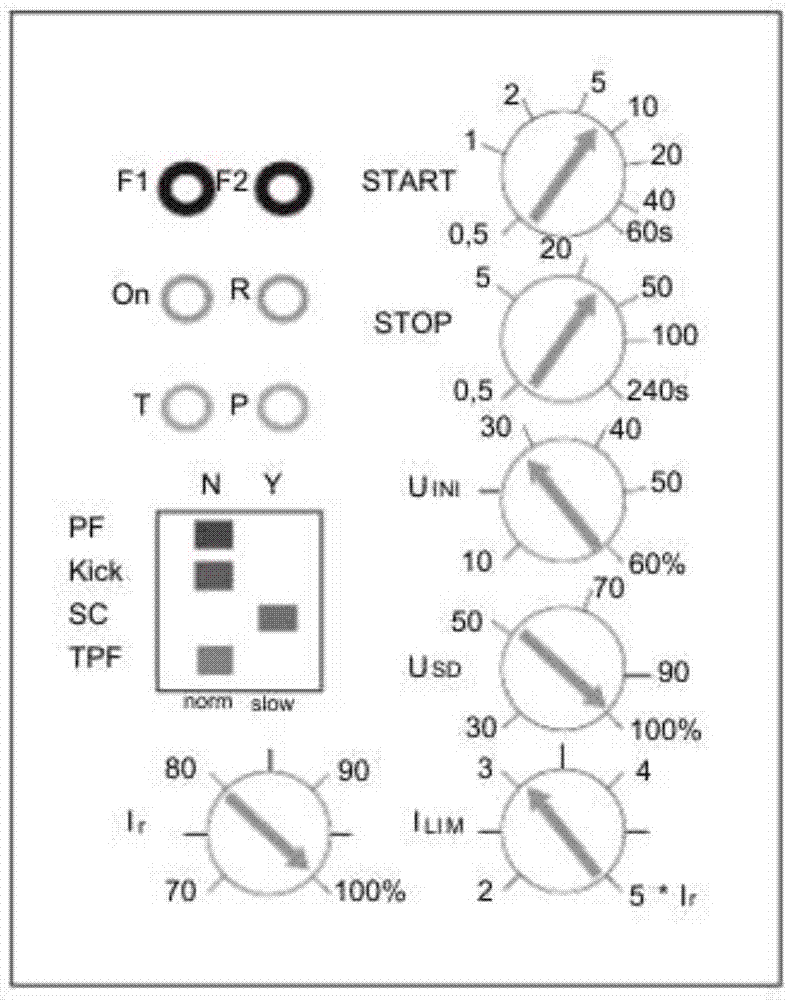

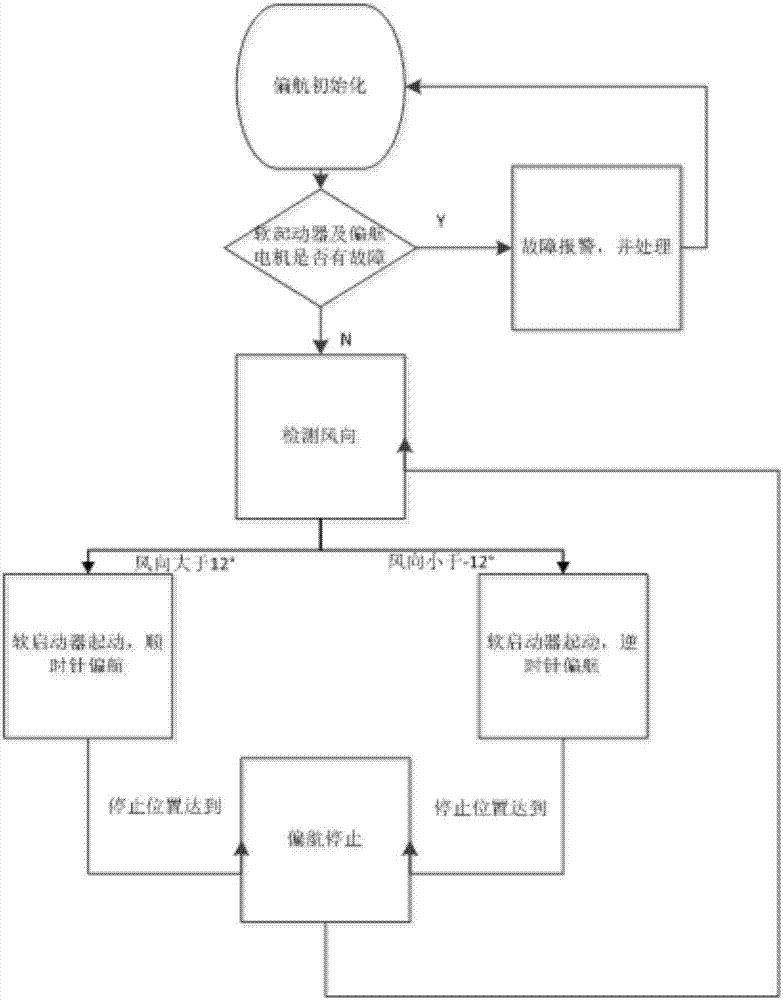

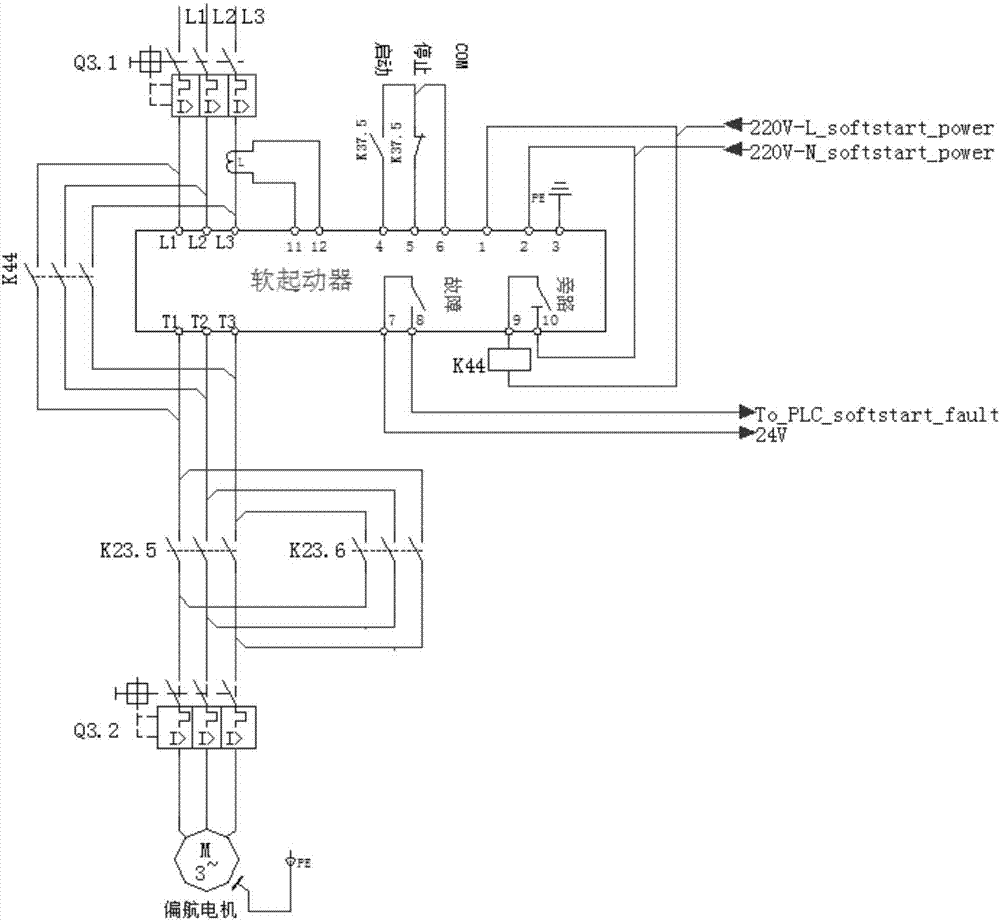

Off-course driving system protection apparatus and method

InactiveCN107359828ANo impactNo inrush currentMotor/generator/converter stoppersDynamo-electric converter controlMechanical equipmentControl theory

The invention belongs to the technical field of a wind power generator, and specifically relates to an off-course gear and off-course motor protection apparatus and method, and applicable to an off-course system of the wind power generator. A soft starter is connected between four sets of off-course motors and a power supply in series; the soft starter adopts a three-phase anti-parallel thyristor as a voltage regulator; and when the motor is started, the output voltage of the thyristor is increased gradually, and the motor is accelerated gradually until the thyristor is fully switched on, and the motor works on mechanical characteristic of a rated voltage. By virtue of the off-course driving system protection apparatus and method, the problems of increasing of maintenance cost of a wind generator set and influence to the use efficiency of a fan caused by abrasion, teeth collision and the like of an acceleration off-course speed reducer and an off-course bearing gear when static mechanical equipment is suddenly loaded with high moment can be solved; and therefore, smooth starting is realized, the starting current is lowered, and tripping caused by start overcurrent can be avoided.

Owner:CHINA CREATIVE WIND ENERGY +3

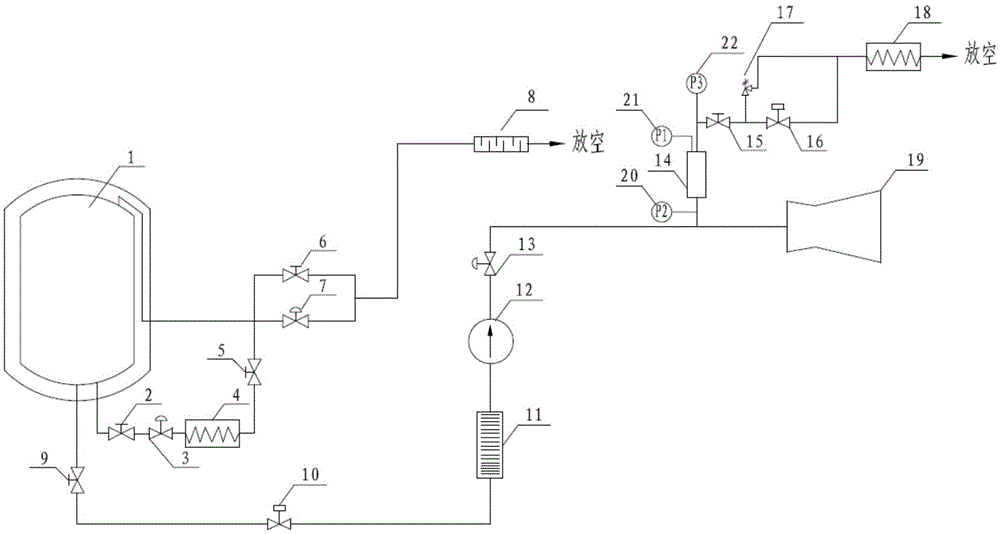

Liquid nitrogen conveying pipeline capable of preventing water attacks

ActiveCN105650474AAvoid water hammerEliminate the effects of water hammerPipeline systemsSingle phaseEngineering

A liquid nitrogen conveying pipeline capable of preventing water attacks comprises a liquid nitrogen tank self-pressurization and pressure-relief pipeline, a liquid nitrogen conveying pipeline, a liquid nitrogen atomizing device and a gas-liquid separation device, wherein the liquid nitrogen tank self-pressurization and pressure-relief pipeline controls pressure of a liquid nitrogen tank through self-pressurization to provide system back pressure for the liquid nitrogen conveying pipeline; the liquid nitrogen conveying pipeline establishes a passage between the liquid nitrogen tank and the liquid nitrogen atomizing device, and the flow of the pipeline is controlled and adjusted by the aid of stop valves and adjusting valves; the liquid nitrogen atomizing device produces various special atomizing effects; the gas-liquid separation device distinguishes gas and liquid phases in the liquid nitrogen conveying pipeline, and gaseous nitrogen in the pipeline is exhausted, so that single-phase liquid nitrogen is conveyed to the tail-end liquid nitrogen atomizing device. According to the liquid nitrogen conveying pipeline capable of preventing the water attacks, pressure stabilization, flow stabilization and attack prevention functions during separation of the gas and liquid phases are realized, influence of the water attacks and pipeline vibration are eliminated, and hazards to pipeline system safety are avoided.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Flour measuring and coutrolling method for electromagnetic valve

InactiveCN101025633AEasy to openIncrease duty cycleFluid pressure control using electric meansElectricityControl system

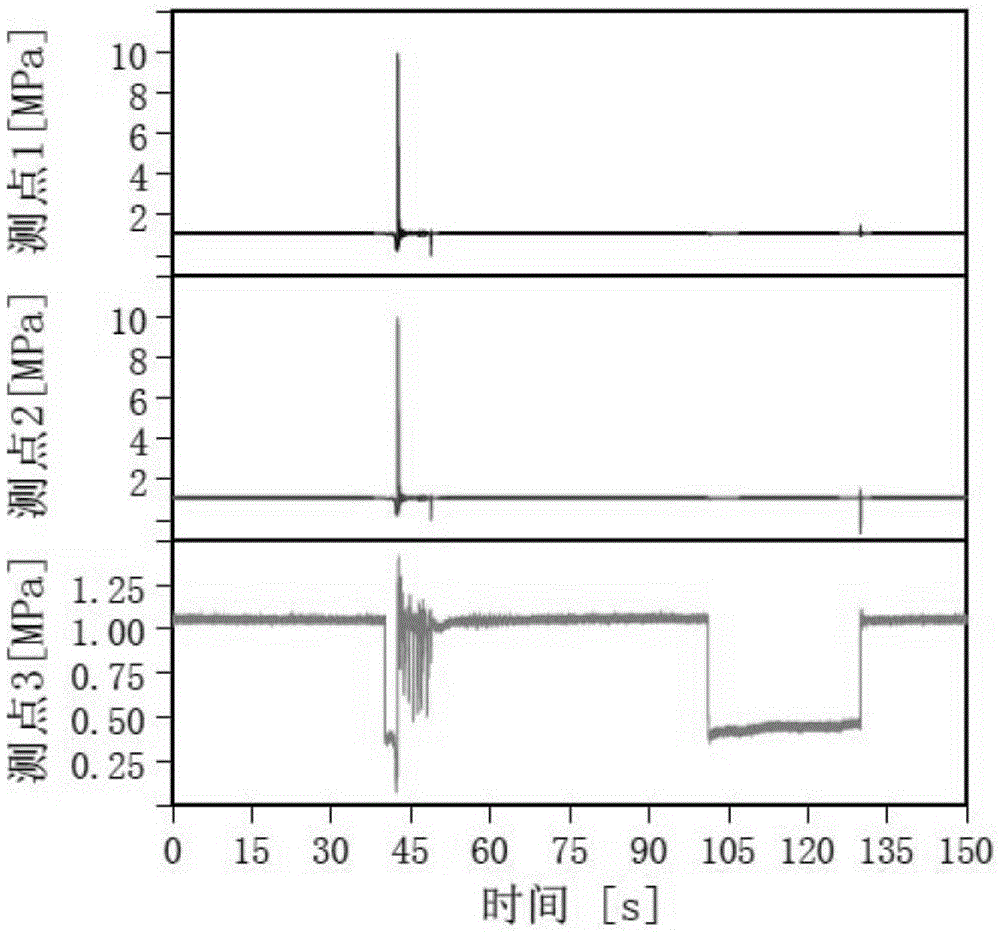

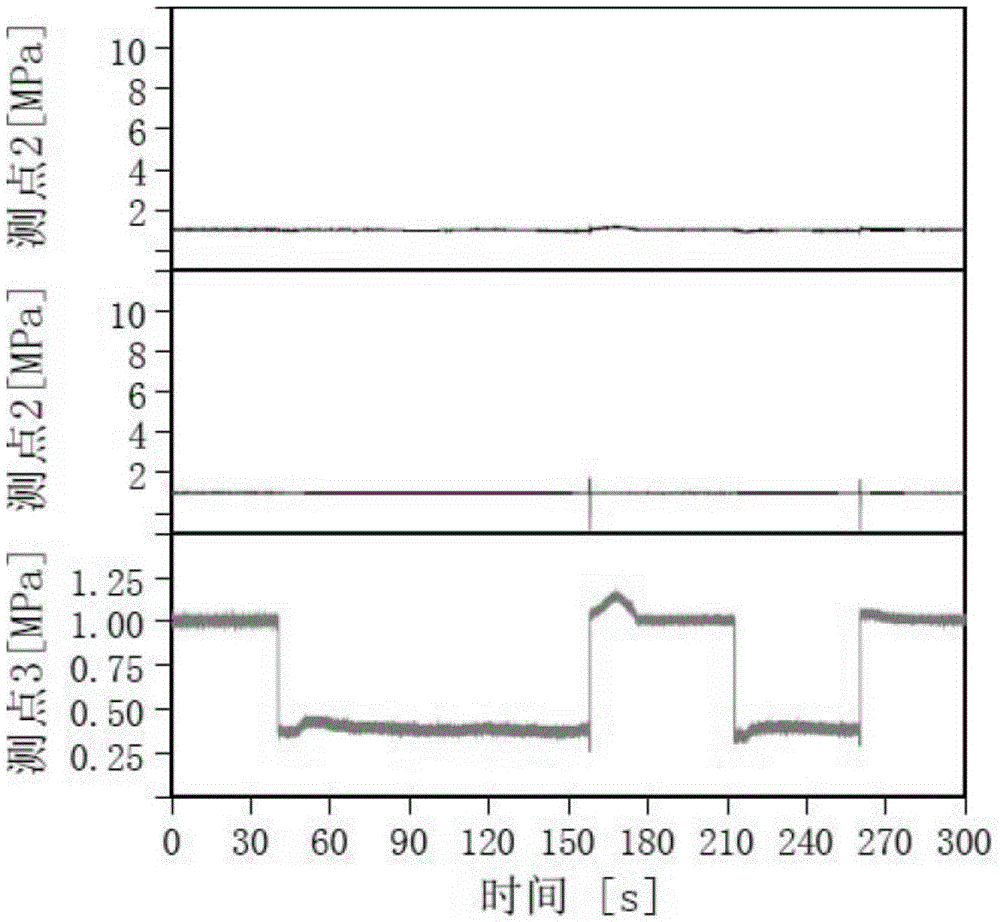

The invention is a flow measuring and control method for measurable and controllable electromagnetic valves, belonging to the automation technical field. And the invention firstly makes measurable and controllable flow electromagnetic valve, signal processing controller and power switch compose a flow measuring and control system, where the measurable and controllable flow electromagnetic valve transmits pressure difference between upper and lower valve fluids to the pressure input port of a pressure difference sensor so that the fluid pressure difference is converted through the pressure difference sensor into fluid pressure difference electric signal to output to the input end of the signal processing controller, the signal processing controller calculates the current detected flow according to the input fluid pressure difference and the output current of an electrified coil and compares it with the given flow to output control instruction to change the current of the electrified coil so as to control the valve opening and achieve the purpose of flow control. And the invention implements integration of flow measurement and control, and can conveniently control regulating rule of the valve opening by algorithm.

Owner:SHANGHAI JIAO TONG UNIV

Steam gas supply system

The invention is a steam-curing steam supply system, comprising several still kettles and several steam curing pools, arranging a steam supply main pipe from steam distributing cylinder in boiler room to these still kettles, and then dividing the main pipe into several steam supply branch pipes to their respective still kettles; the main pipe is equipped with a steam supply master valve whose tail end is equipped with a shutoff valve and a drain valve, and a steam backing main pipe between these still kettles and these steam-curing pools and one end of the steam backing main pipe adjacent to the still kettles is divided into several steam backing branch pipes connected with their respective still kettles and the other end is divided into several steam inlet branch pipes to the respective steam-curing pools.

Owner:梁锡武

Low-temperature pneumatic valve time delay unit

InactiveCN104633250AAvoid cloggingImprove securityOperating means/releasing devices for valvesValve members for absorbing fluid energyTime delaysEngineering

A low-temperature pneumatic valve time delay unit belongs to the technical field of pneumatic control. The time delay unit comprises a gas inlet, a filter, a gas outlet, a valve body, a valve element, an adjusting rod and a pressing cover, wherein the valve body is provided with a flow guide groove and a gas hole. After the low-temperature pneumatic valve time delay unit is arranged in a pneumatic valve starting gas pipeline, gas needs to pass through the gas inlet and the filter to enter the valve element, passes through a throttling opening in the valve element to flow into a gas cavity formed by the valve body, the valve element, the pressing cap and the flow guide groove, and then flows into the gas outlet from one side of the valve body so as to enter a valve pneumatic execution mechanism to drive the valve to be opened and closed. The position of screwing the adjusting rod into the valve element is adjusted so that the gas flow of the gas entering the valve pneumatic execution mechanism can be controlled, and furthermore, the valve obtains different opening and closing delaying time. The low-temperature pneumatic valve time delay unit is compact and reasonable to assembly and is simple and convenient to operate in a use process; the adjustable range is wide and the time delaying function is stable.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

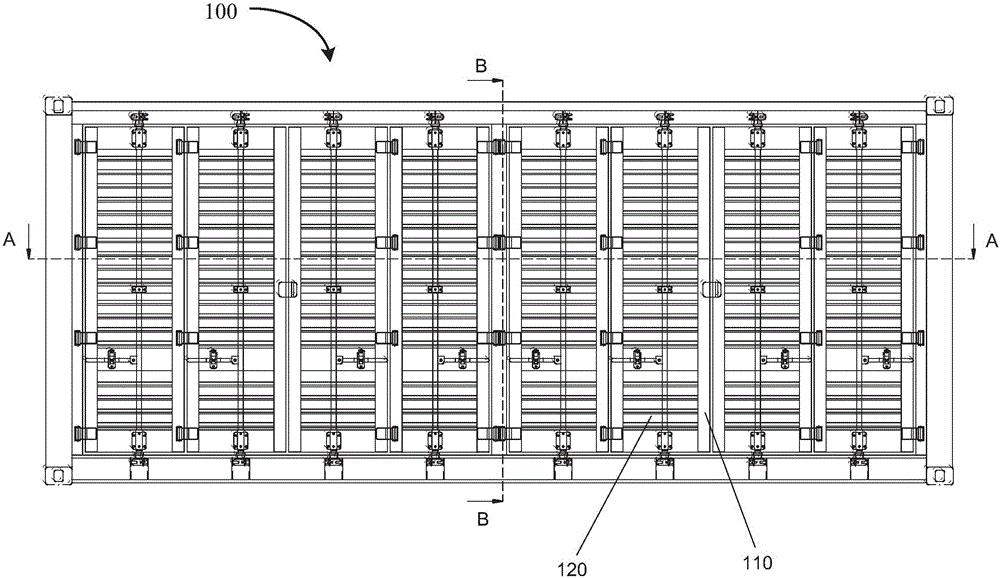

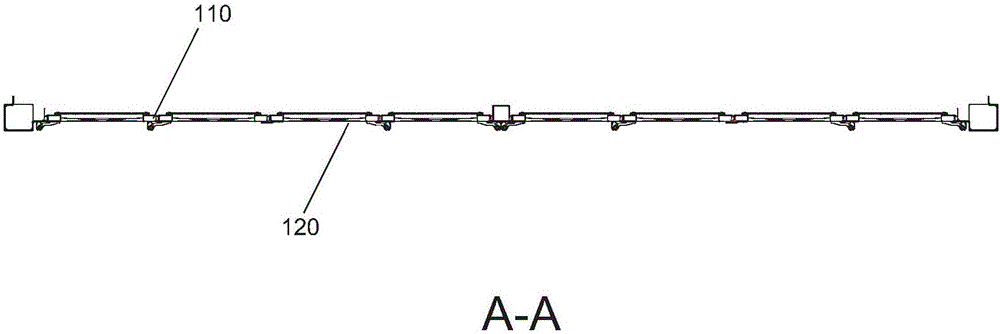

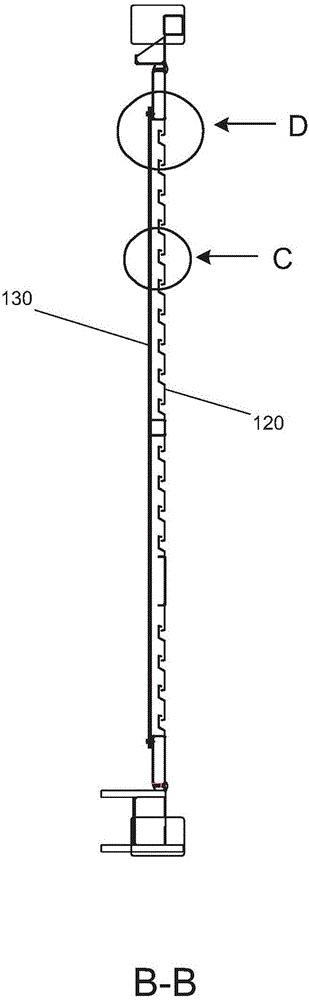

Lover window and container with same

InactiveCN106246080AAvoid pollutionAvoid water hammerInsect protectionLarge containersEngineeringLouver

The invention discloses a louver window and a container with the same. The louver window comprises a window frame and a plurality of louver blades, the louver blades comprise a blade body, a first shade portion and a second shade portion, the first shade portion extends out from the top end of the blade body, and the second shade portion extends in from the bottom end of the blade body, wherein the louver blades are configured to be arranged in a vertically staggered manner within the window frame along the height of the louver window, and the lower one of upper and lower adjacent louver blades has the first shade portion mating with the second shade portion of the upper one, so that the first shade portion of the lower one is positioned on the inner side of the second shade portion of the upper one. According to the invention, watertight and dustproof effects of the louver window can be improved.

Owner:YANGZHOU RUNYANG LOGISTIC EQUIP +2

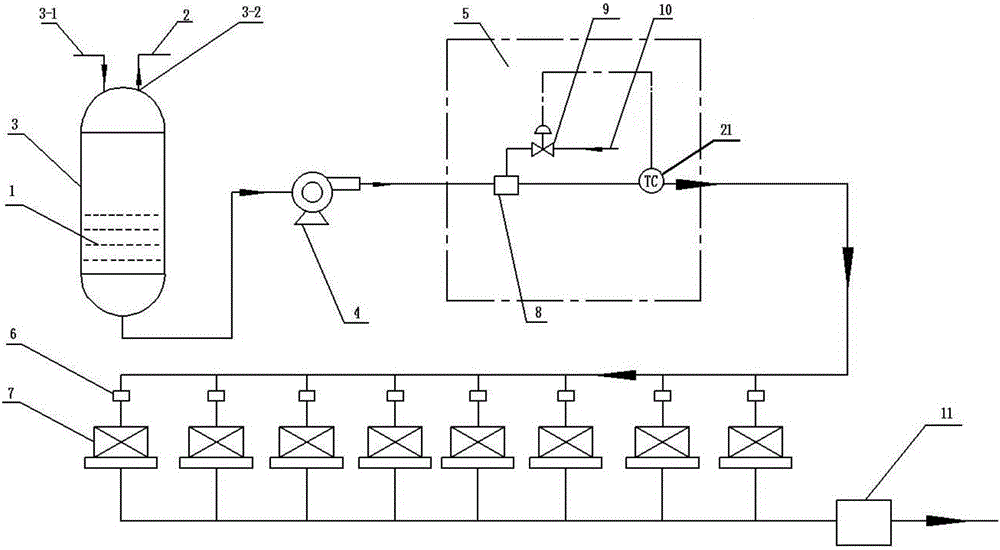

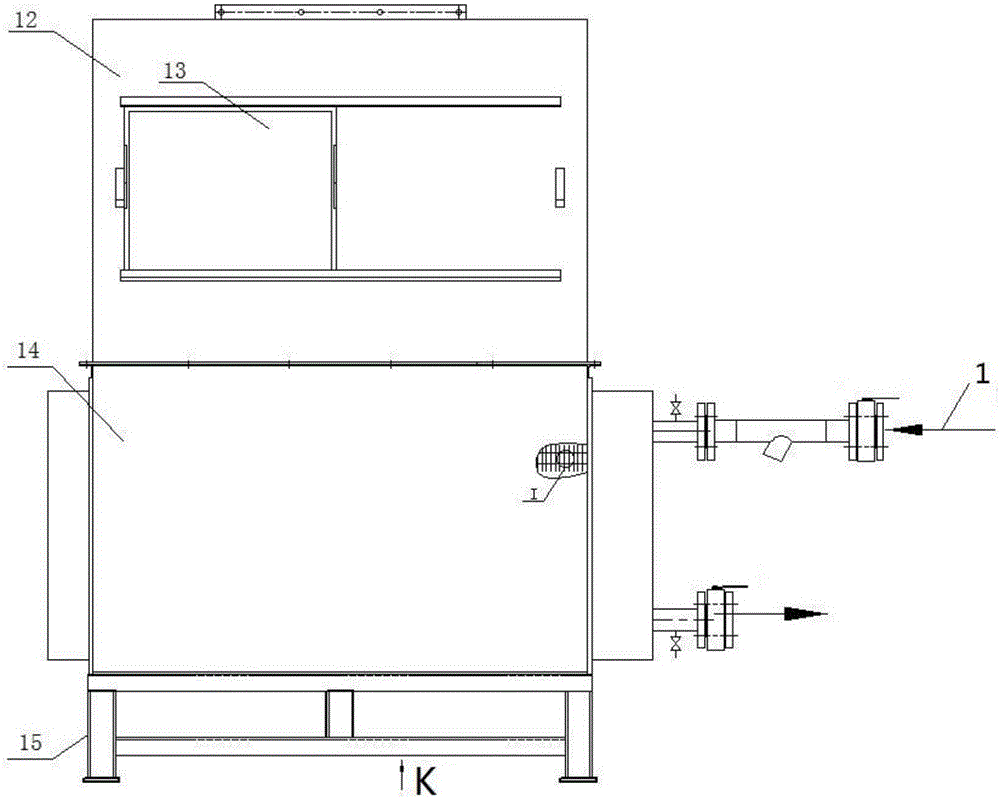

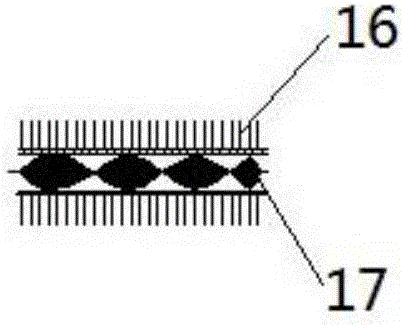

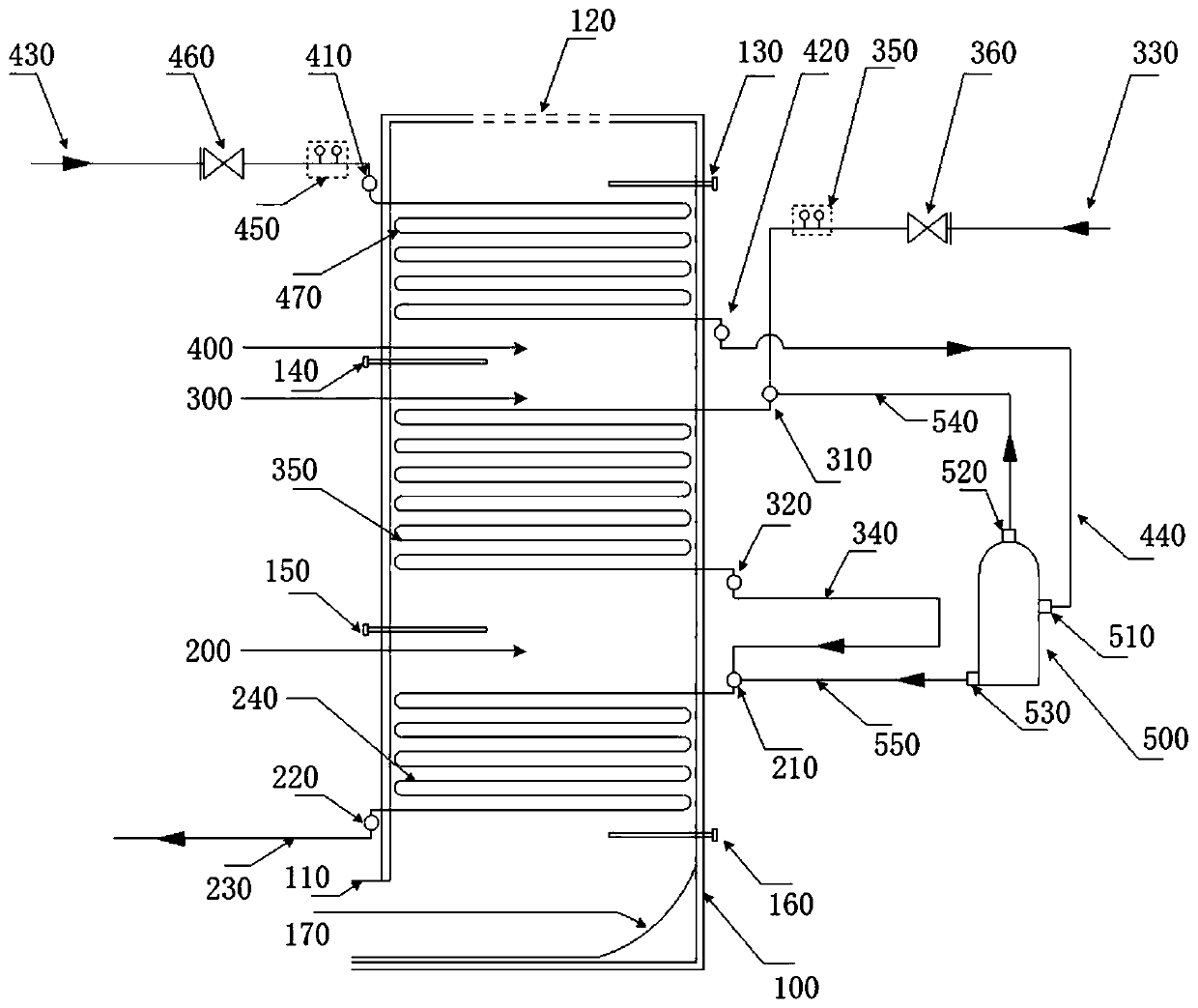

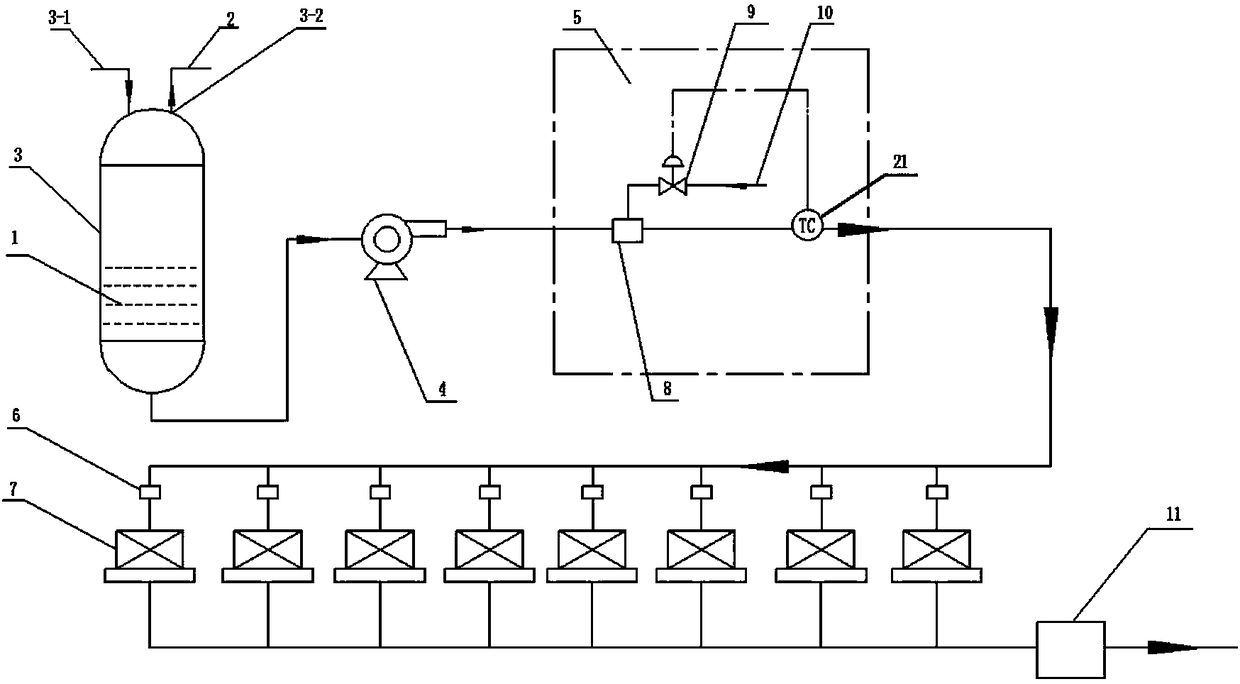

Air preheating device and method of large negative-pressure heating furnace

ActiveCN106196145ASolve traffic distribution problemsAvoid water hammerCombustion processIndirect carbon-dioxide mitigationReducerEngineering

The invention relates to an air preheating device and method of a large negative-pressure heating furnace. The air preheating device comprises a flash tank, a centrifugal pump, a temperature reduction system, preheating device bodies and a water returning system, wherein the flash tank is sequentially connected to the centrifugal pump, the temperature reduction system, flow controllers, the preheating device bodies and the water returning system through a pipeline; saturate condensate liquid is contained inside the flash tank and is conveyed out for being further utilized after sequentially flowing through the centrifugal pump, the temperature reduction system, the preheating device bodies and the water returning system; and the multiple preheating device bodies can be arranged and are connected between the temperature reduction system and the water returning system in parallel through a pipeline. According to the technical scheme, the flow distribution problem of the preheating device bodies is effectively solved, the system operation stability is guaranteed through a temperature reducer, the energy conservation efficiency is improved by reinforcing the heat exchange measures, and the production cost is lowered.

Owner:北京联创鼎新石化设备有限公司

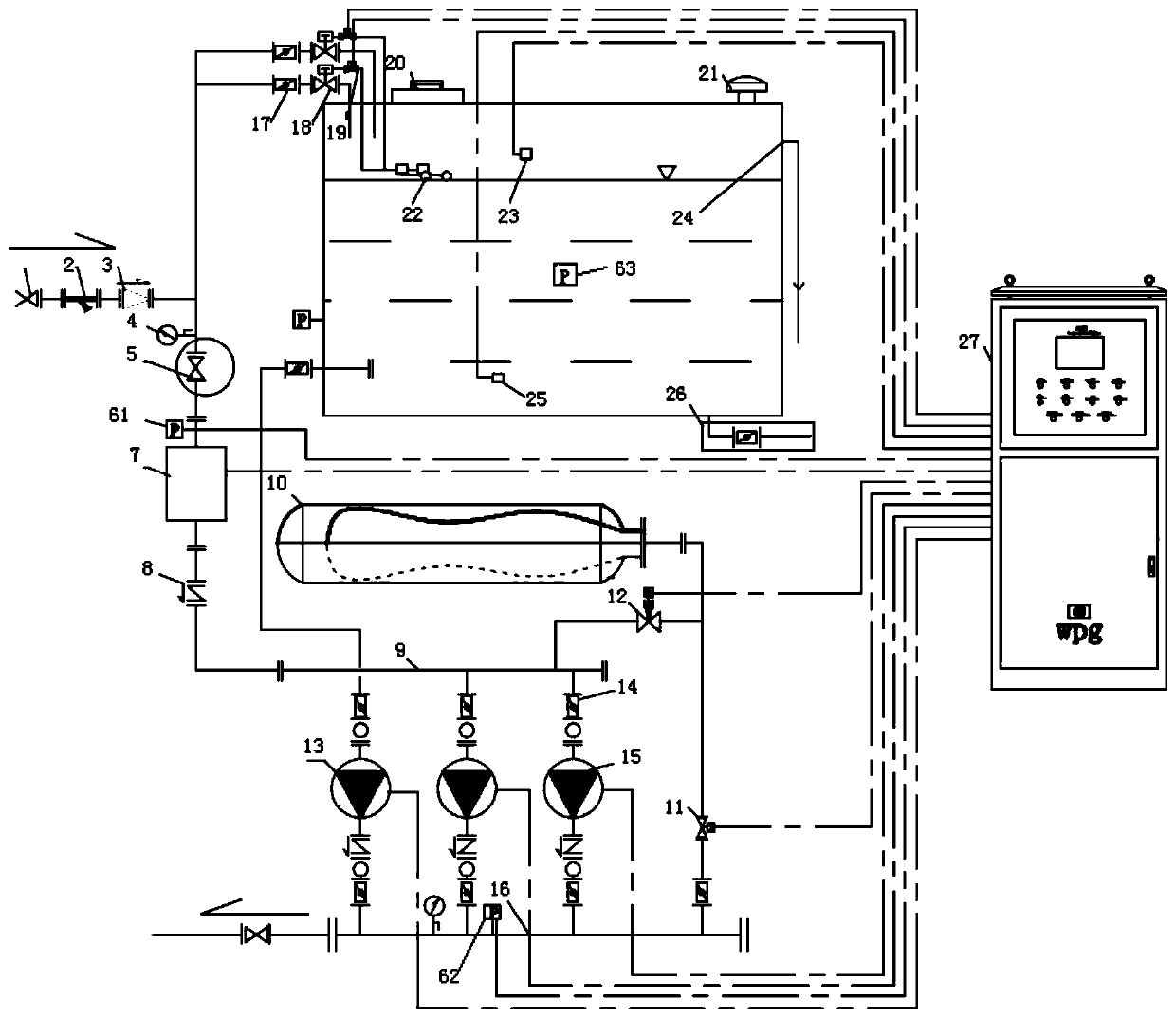

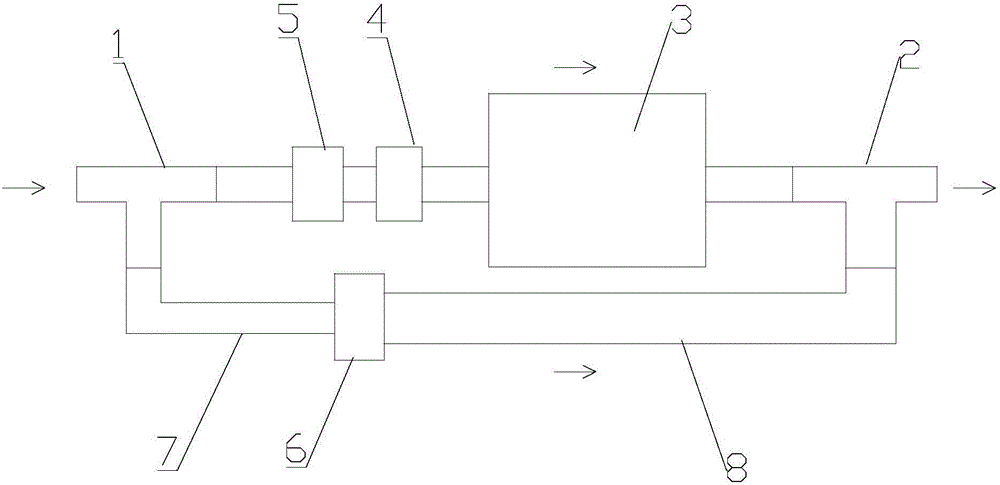

Non-negative pressure water supply device and working method thereof

InactiveCN110056045AAvoid affecting service lifeAvoid water hammerService pipe systemsWater mainsInlet channelWorking set

The invention discloses a non-negative pressure water supply device. The non-negative pressure water supply device comprises a municipal water inlet channel, a pressure-stabilizing compensation tank,a pressurized pipeline, a main pump assembly and an intelligent control cabinet; the municipal water inlet channel is connected with an inlet end of a municipal water passage and a water inlet end ofa water tank correspondingly, and the municipal water passage communicates with a first summary pipe; the outlet end of the pressure-stabilizing compensation tank communicates with the first summary pipe through an electromagnetic pressure reducing valve, and the outlet end of the pressure-stabilizing compensation tank further communicates with a second summary pipe through an electromagnetic valve; one end of the pressurized pipeline is disposed in the water tank, the other end of the pressurized pipeline communicates with the second summary pipe, and the pressurized pipeline is provided witha water tank water-taking boosting pump; one end of the main pump assembly is disposed in the first summary pipe, and the other end of the main pump assembly is disposed in the second summary pipe; and the intelligent control cabinet controls the entire non-negative pressure water supply device. The non-negative pressure water supply device directly takes water from the water tank and pressurizesthe water to the second summary pipe through the water tank water-taking boosting pump, the service life of the water pump is prevented from being affected, and a water hammer effect is avoided. A third material table and a third waste material table are disposed; and a first robot is located between a second material table and the third material table.

Owner:SHANGHAI WPG WISDOM WATER CO LTD

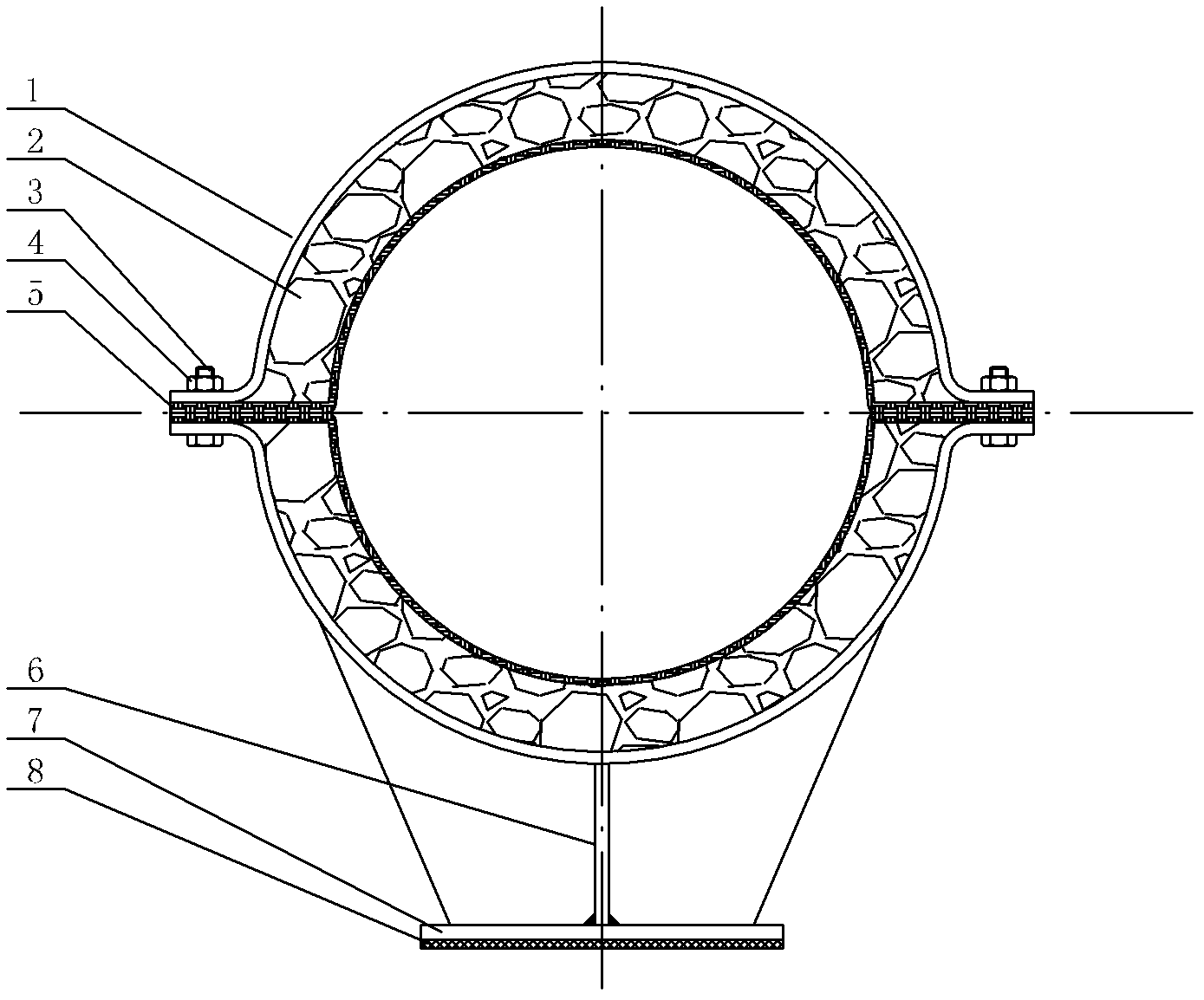

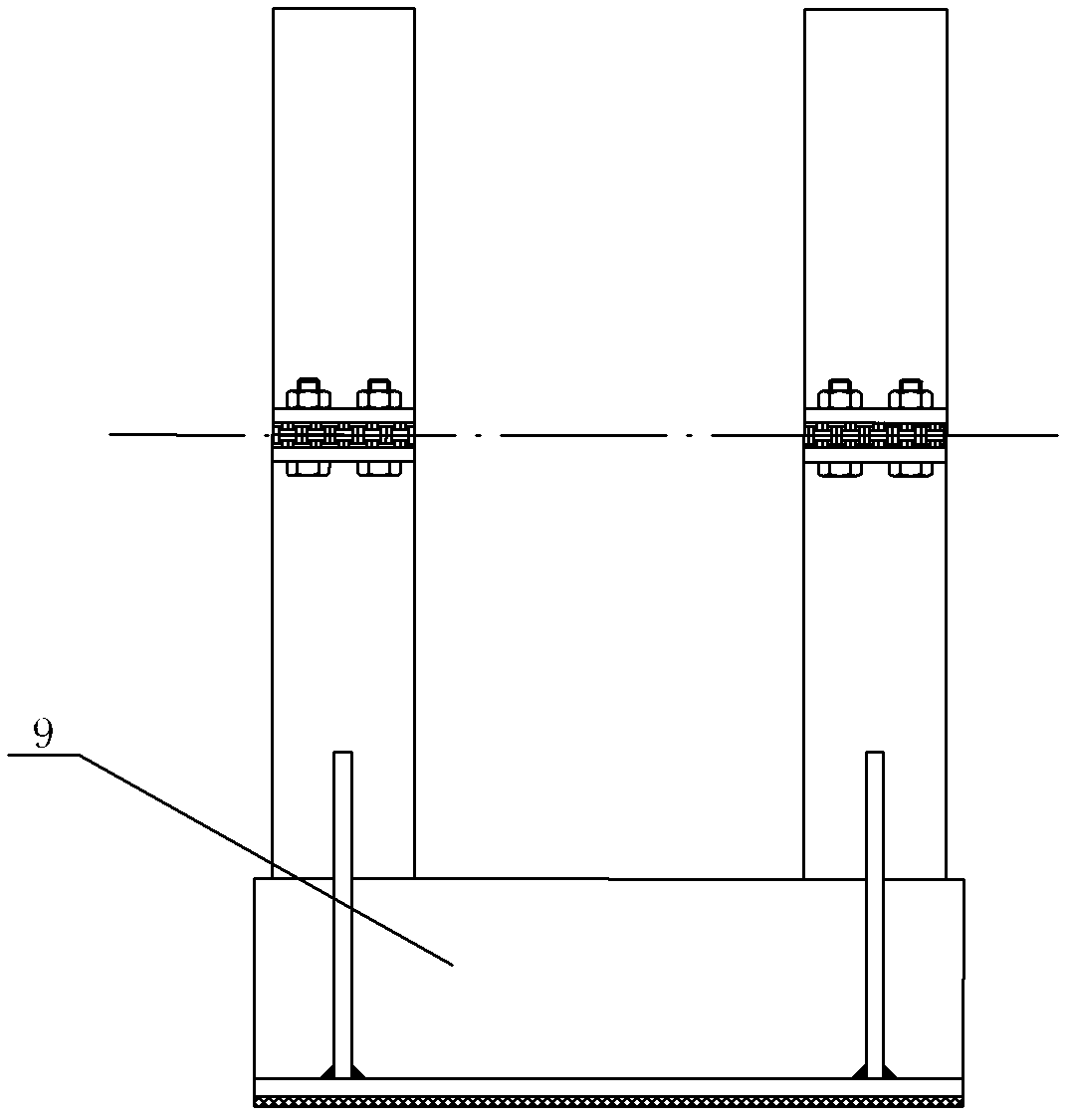

Sliding heat insulation pipe bracket with gradient

InactiveCN102359698AGood heat insulationHigh compressive strengthThermal insulationPipe elementsSlide plateEngineering

The invention relates to a heat insulation pipe bracket for steam pipeline transportation, in particular to a sliding heat insulation pipe bracket with gradient, and belongs to the technical field of steam pipeline transportation. The bracket comprises two heat insulation pipe brackets and a base, wherein a hoop, a heat insulation tile and a heat insulation felt are arranged in each heat insulation pipe bracket; a rib plate, a support seat bottom plate, a sliding plate and vertical plates are arranged in the base; the two sliding heat insulation pipe brackets are fixed on the support seat bottom plate through the rib plate vertical to a fixing part; the sliding plate is arranged below the support seat bottom plate; the two vertical plates are obliquely connected with the heat insulation pipe brackets and the support seat bottom plate; and the gradient of the vertical plates is adjusted specifically according to the actual using condition. The heat insulation bracket with the gradient has a good heat insulation effect, high compression strength and a reasonable and effective structure and is convenient to produce and easy to massively popularize; and the inherent defect of the original structure is effectively overcome after the heat insulation bracket is actually applied to heat supply network engineering of a mine-mouth power plant in Longyan, Fujian.

Owner:无锡市明江保温材料有限公司

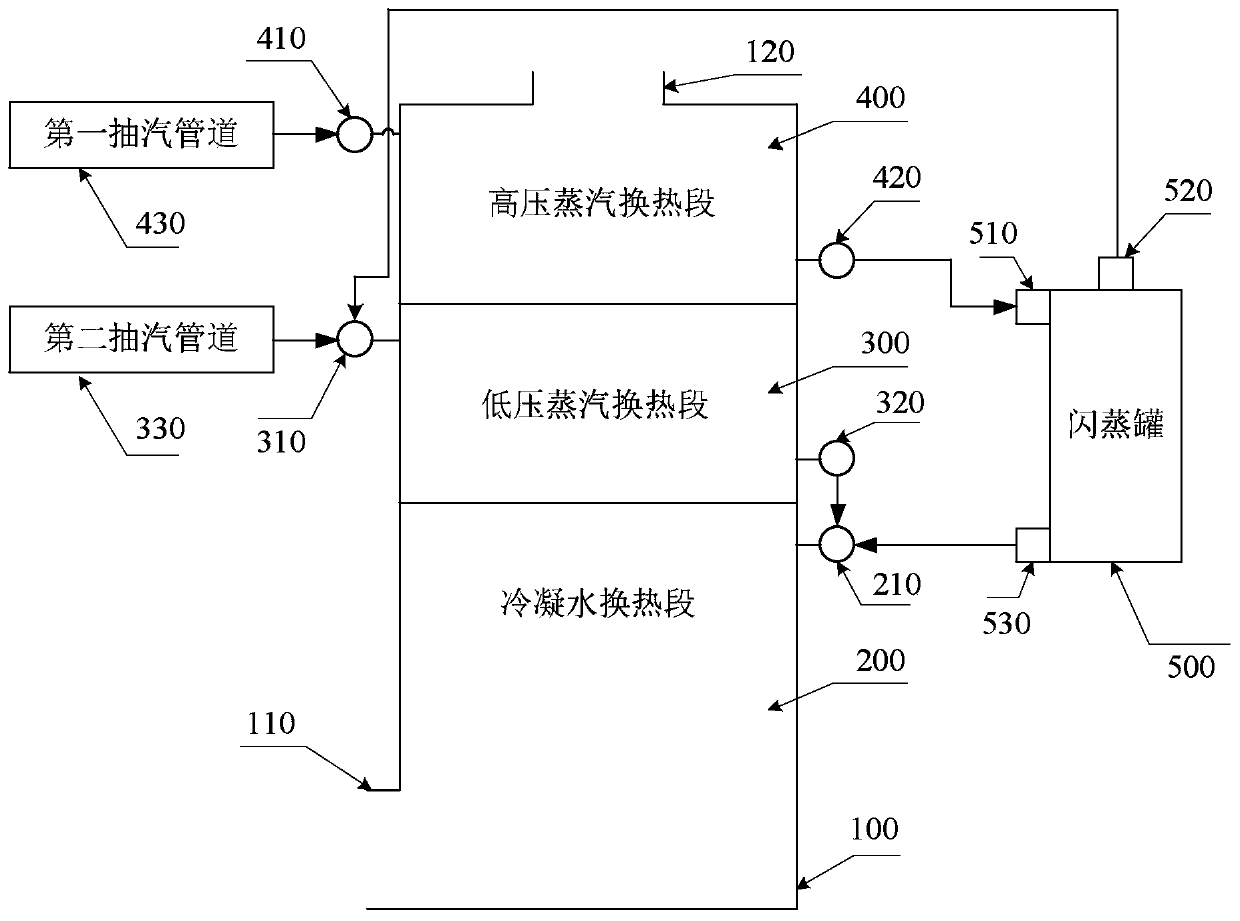

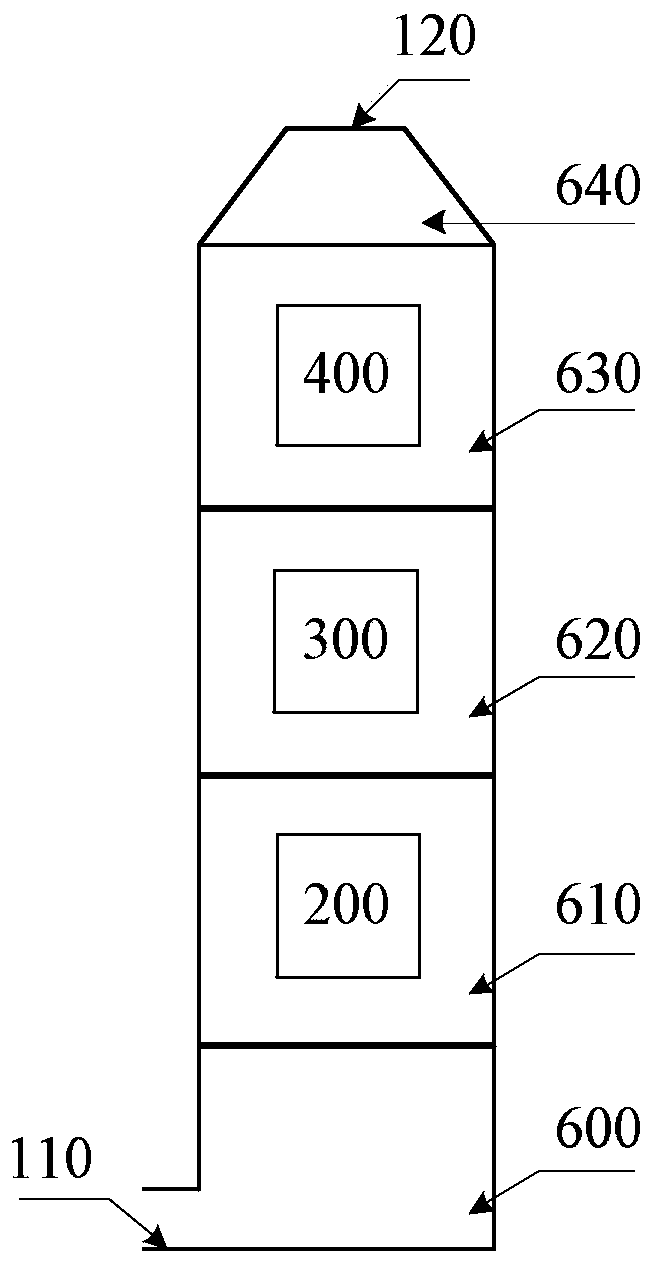

Steam-air preheating device and system

PendingCN109798536AEfficient use ofImprove heat transfer efficiencyLiquid degasificationCombustion processEngineeringHigh pressure

The embodiment of the invention discloses a steam-air preheating device and system. The steam-air preheating device comprises a box body, a condensate heat-exchange section, a low-pressure steam heat-exchange section, a high-pressure steam heat-exchange section and a flash tank; an inlet header of the high-pressure steam heat-exchange section is connected with a first steam-extraction pipeline, and an outlet header of the high-pressure steam heat exchange section is connected with an inlet of the flash tank; an inlet header of the low-pressure steam heat-exchange section is connected with a second steam-extraction pipeline and a first outlet of the flash tank; and an inlet header of the condensate heat-exchange section is connected with an outlet header of the low pressure steam heat-exchange section and a second outlet of the flash tank. The steam-air preheating device and system achieves the effects that steam and condensate are effectively utilized to recover heat, the heat-exchangeefficiency is improved and the steam extraction amount is decreased, the water hammer phenomenon is avoided, and operation of the system is more economical, more efficient, safer and more reliable.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Plant irrigation platform for rock ecological restoration

InactiveCN112974025AIrrigation implementationAvoid water hammerLiquid spraying apparatusHorticulture methodsEngineeringEnvironmental engineering

The invention relates to the field of rock ecological restoration, in particular to a plant irrigation platform for rock ecological restoration, and can realize plant restoration liquid irrigation on plants. The platform comprises a gas pressurization assembly, a one-way valve assembly, a water tank assembly, a power assembly and a nozzle assembly, wherein under the action of air, plant restoration liquid flows into a liquid cavity through a connecting pipe, liquid diversion is achieved through a liquid diversion boss, the water hammer effect is prevented, the plant restoration liquid obtained after liquid diversion flows out through a spray pipe, the plants are irrigated, and meanwhile, a manual rotating rod and the spray pipe are relatively rotated, so that the area between adjusting plates is changed, and the flow of the plant restoration liquid discharged in unit time is adjusted.

Owner:王洪亮

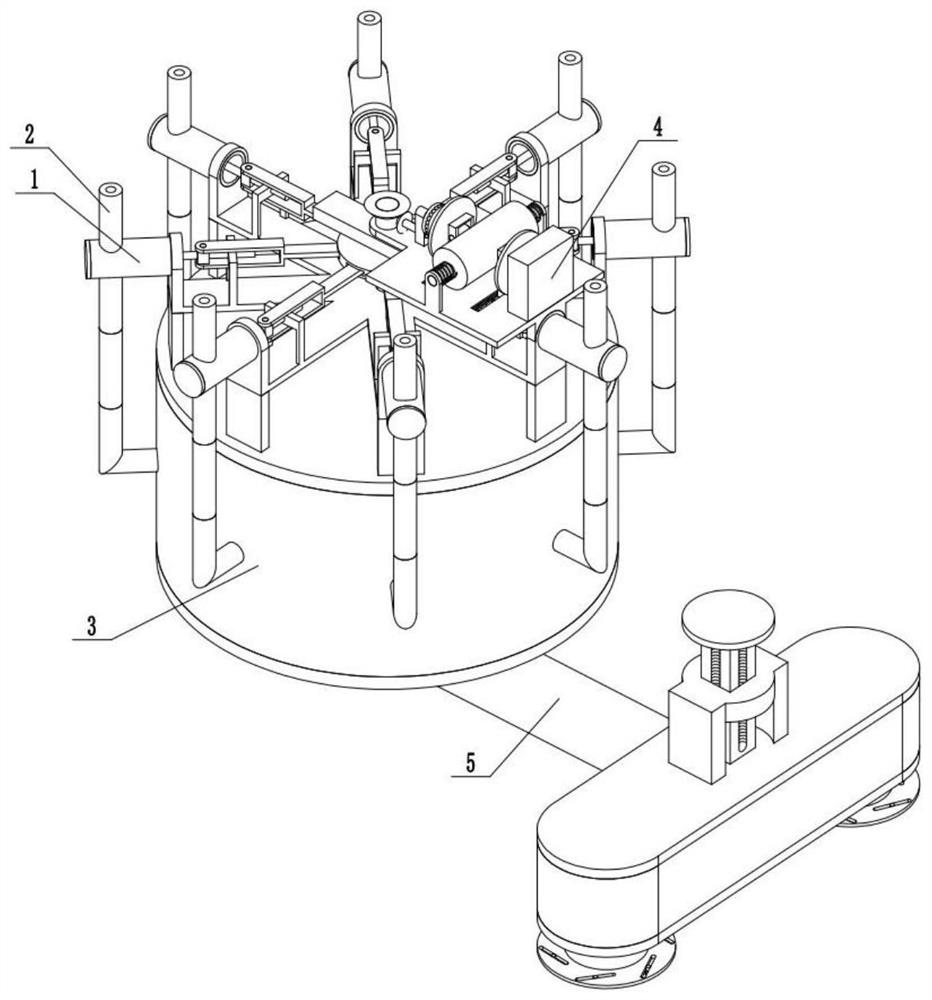

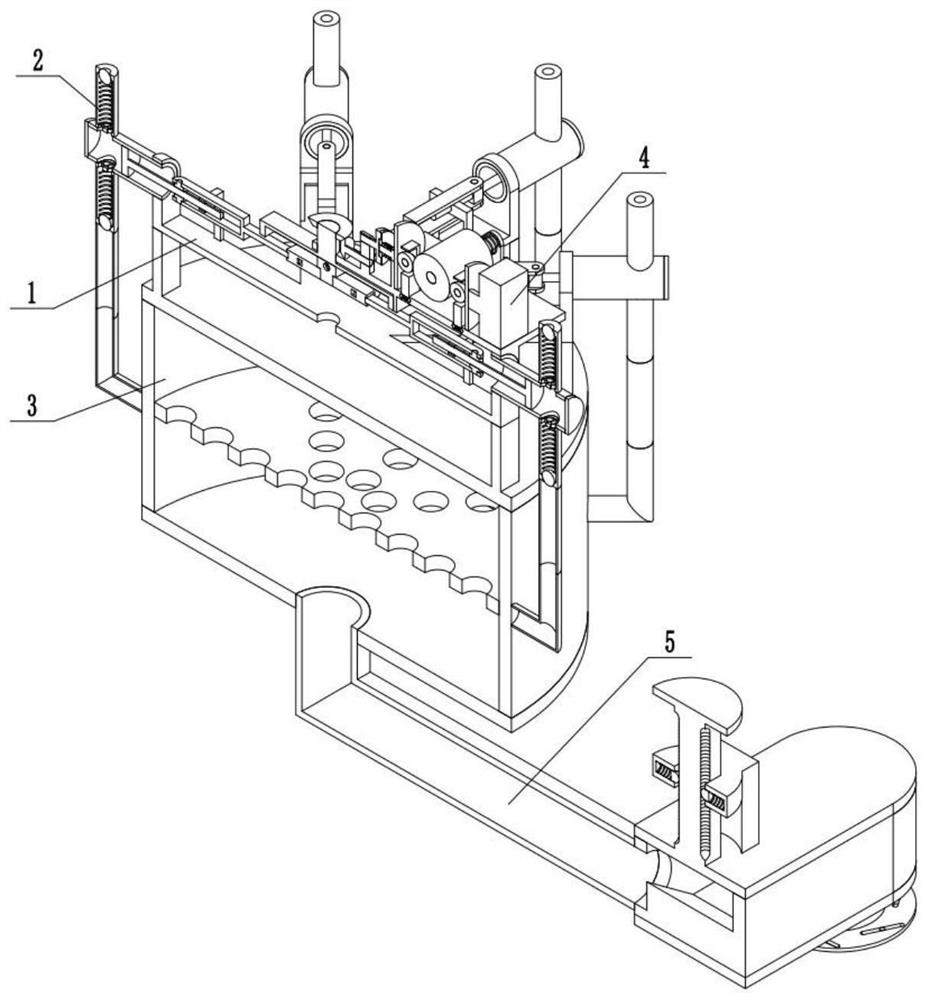

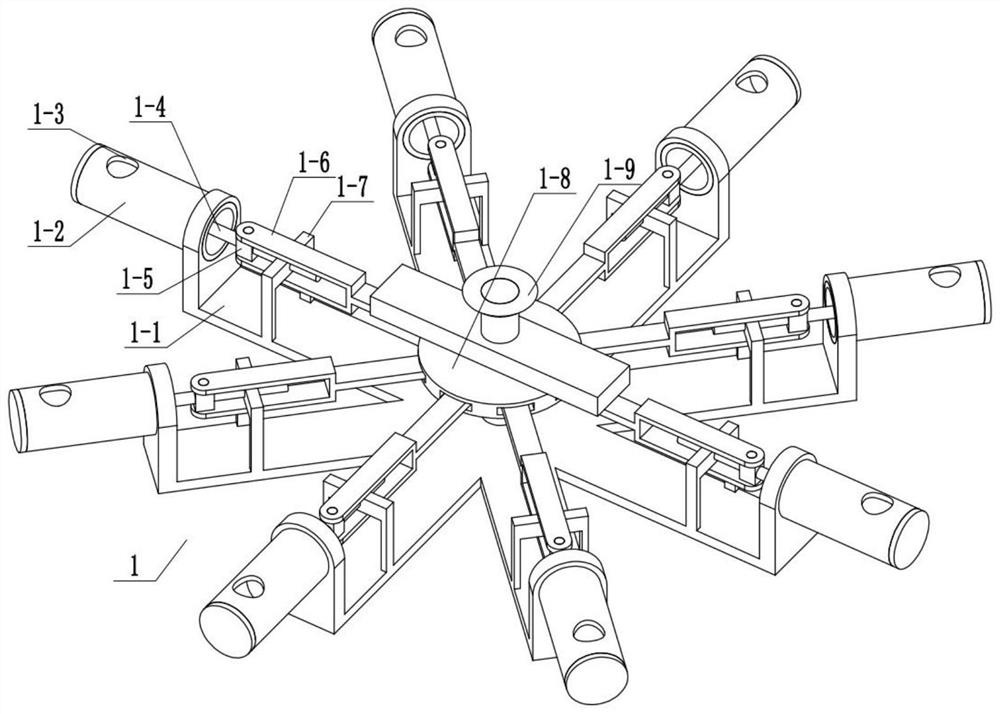

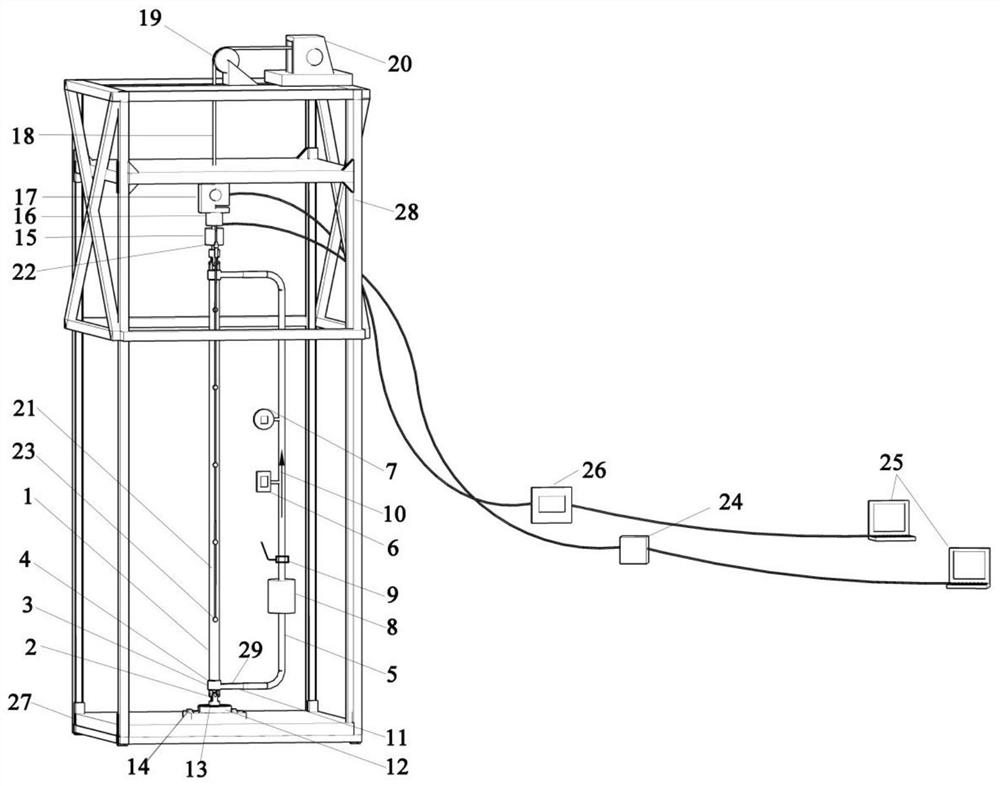

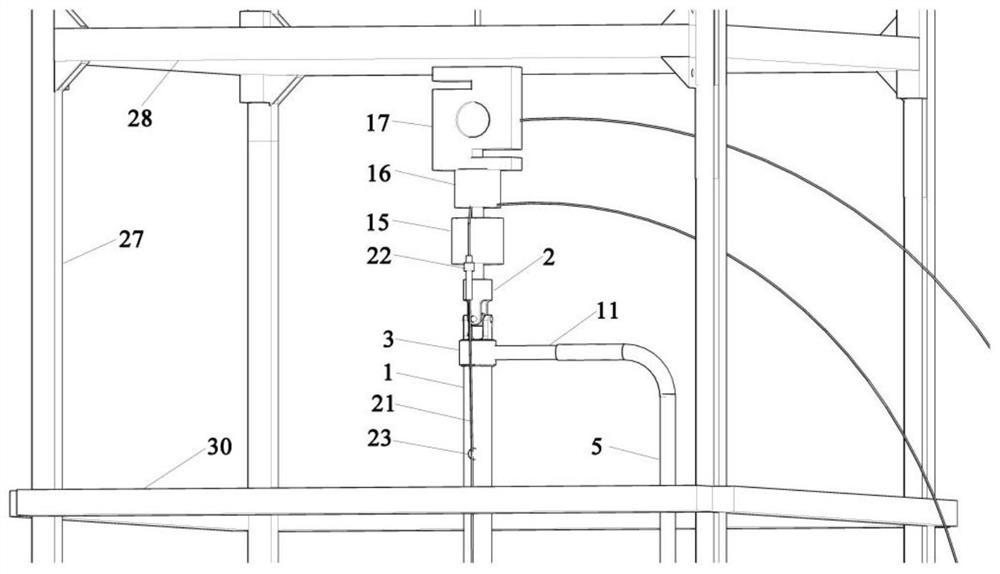

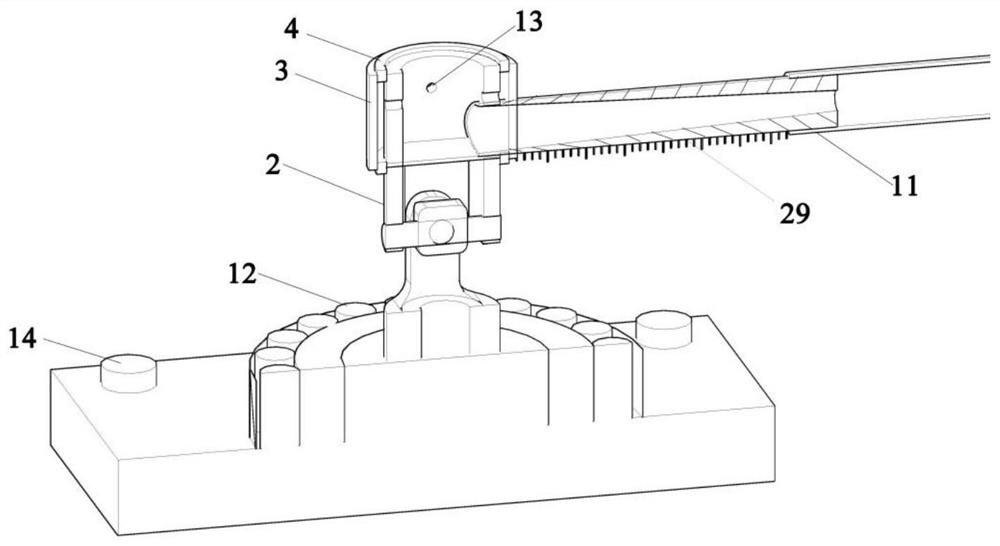

Vibration test device for composite riser-free drill string coupled with drilling fluid circulation

PendingCN113405770AReduce shockGuaranteed impactHydrodynamic testingVibration testingRotational axisData monitoring

The invention discloses a vibration test device for a composite riser-free drill string coupled with drilling fluid circulation, wherein the vibration test device comprises a drill string model placed in a wave flow combined water tank, load excitation equipment, a drilling fluid circulating device and a data monitoring sensing device, and the load excitation equipment is connected to the top end of a riser-free drill string; the drill string model and the drilling fluid circulating device are connected with a data monitoring sensing device; and the drilling fluid circulating device is connected with the drill string model through a telescopic sleeve, and the drill string model is embedded into a rotating bearing through a universal joint connected with the bottom of the drill string model and connected to a fixing plate at the bottom of a supporting device through a high-strength bolt and a nut. Technical support is provided for drill string optimization, strength check and optimization of operation parameters and drilling parameters of the riser-free drilling technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Low-pressure steam condensation water energy saving system and method for alkane dehydrogenation device

InactiveCN105478064AOvercoming water hammer vibration problemsEasy to operateChemical/physical/physico-chemical processesSaline waterAlkane

The invention discloses a low-pressure steam condensation water energy saving system and method for an alkane dehydrogenation device. The method comprises the following steps: controlling the flow of desalted water according to the temperature and pressure of low-pressure steam condensation water, and fully mixing the desalted water with the low-pressure steam condensation water in a condensation water attemperator so as to cool to 40 DEG C, wherein the cooled condensation water is used as a water source of an efficient compound air cooler of the alkane dehydrogenation device or enters a low-pressure steam condensation water recovery header pipe and is finally pumped out of the device, thus achieving the effect of energy-saving utilization.

Owner:BEIJING HUAFU ENG

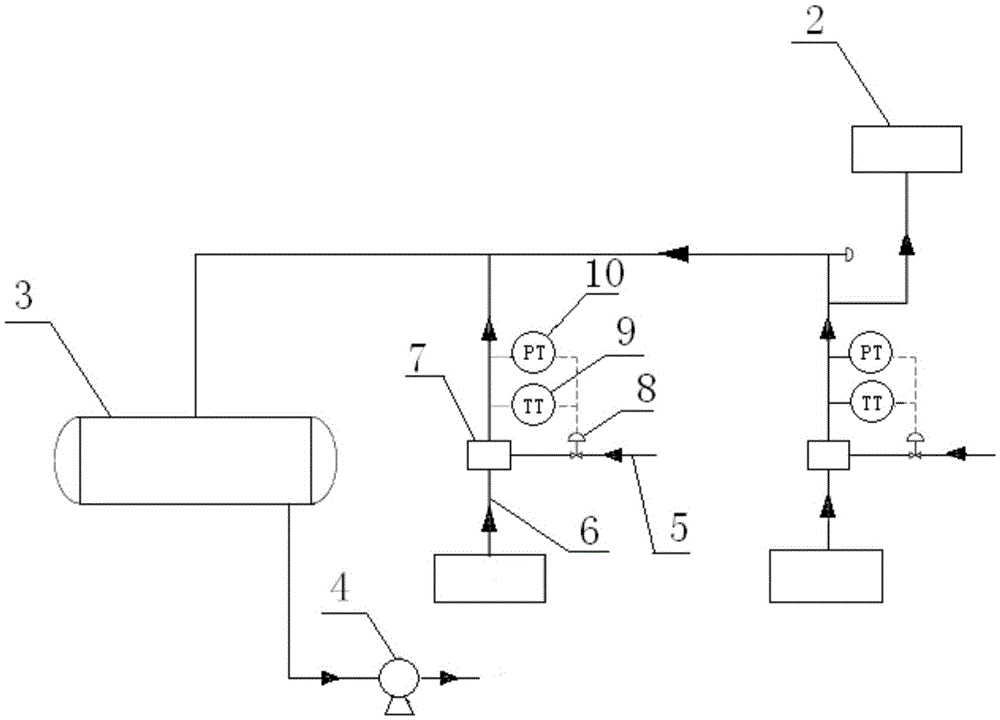

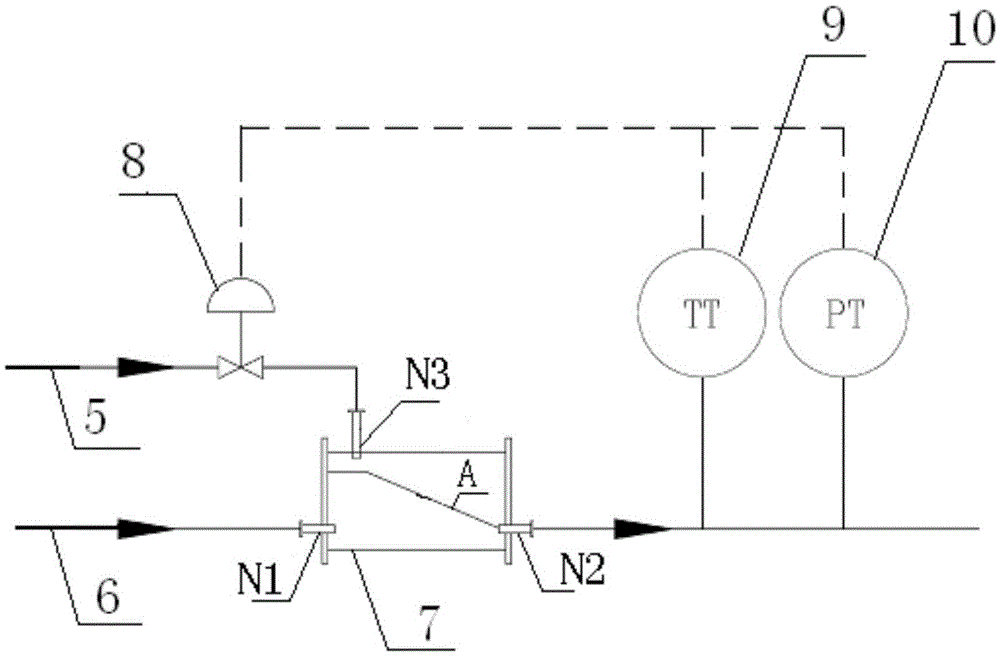

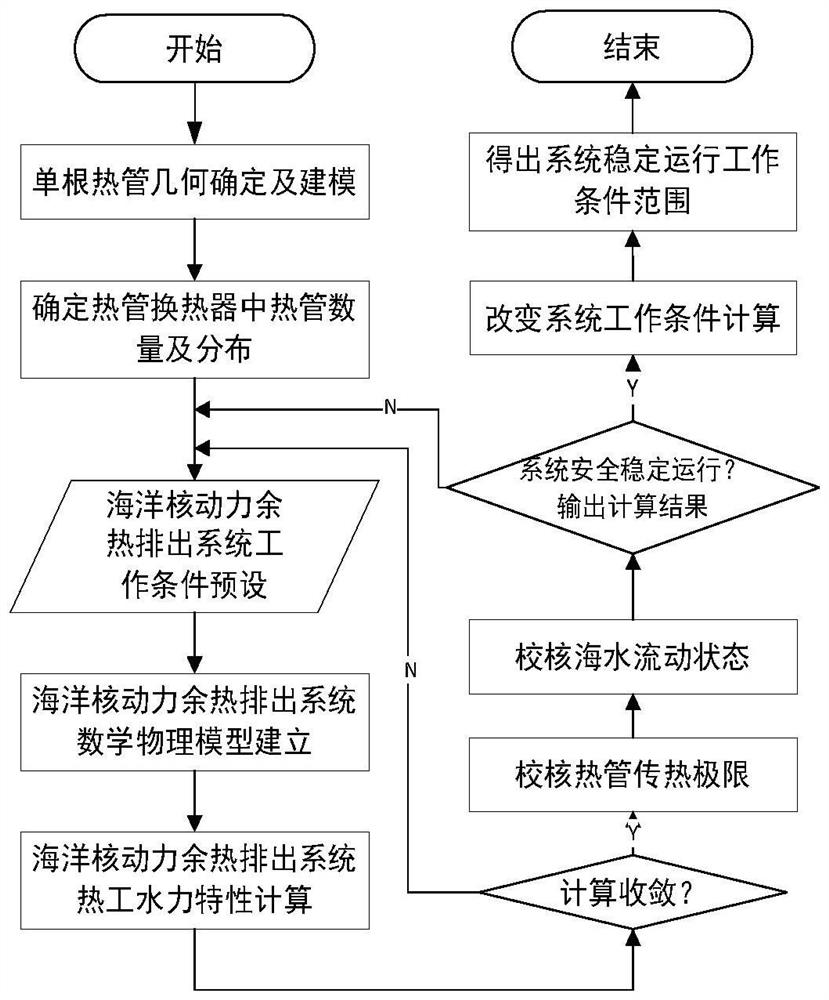

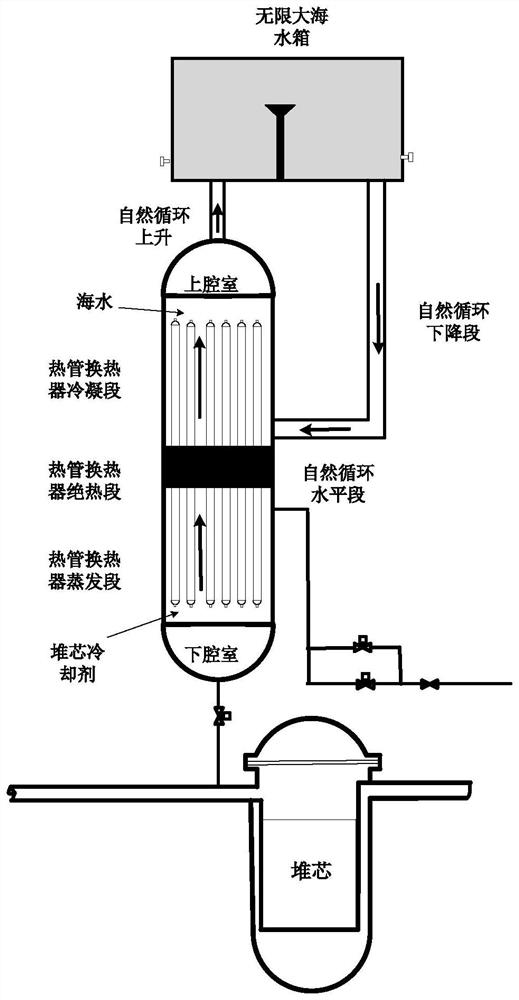

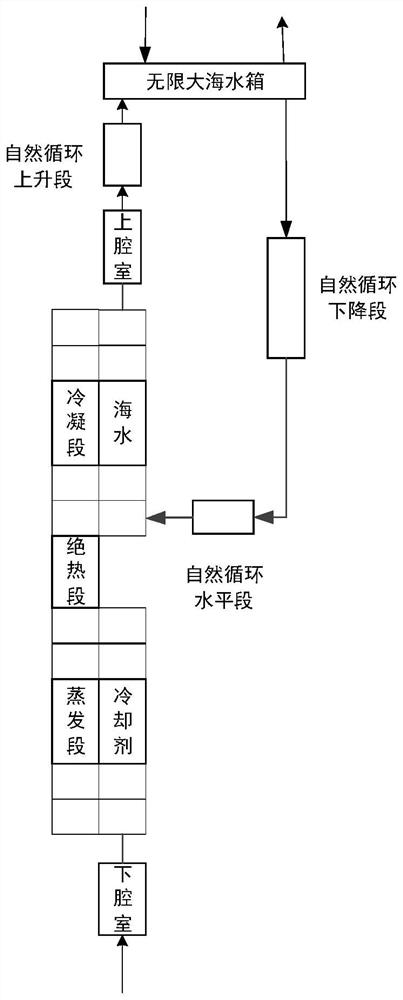

Marine nuclear power heat pipe type waste heat removal system stable operation condition analysis method

PendingCN113948229AAvoid safety hazardsAvoid water hammerNuclear energy generationCooling arrangementThermal hydraulicsSeawater

The invention provides a marine nuclear power heat pipe type waste heat removal system stable operation condition analysis method which comprises the steps: 1, determining heat pipe parameters, and establishing a heat pipe model; 2, determining the number and distribution of heat pipes in a heat pipe exchanger; 3, initially setting working conditions of the marine nuclear power heat pipe type waste heat removal system; 4, establishing a mathematical physical model of the marine nuclear power heat pipe type waste heat removal system; 5, calculating the thermal hydraulic characteristics of the system through a Gear algorithm; 6, checking whether the heat pipe has a heat transfer limit or not, wherein the system is unstable if the heat transfer limit occurs; 7, checking the seawater flowing state and the outlet supercooling degree of the marine nuclear power heat pipe type waste heat removal system, and if nucleate boiling occurs or the supercooling degree is smaller than 10 DEG C, indicating that the system is unstable; 8, if any one of the steps 6 and 7 occurs, carrying out the steps 3-7 again, otherwise, outputting a calculation result; 9, changing working conditions, repeating the steps 3-8, and obtaining the working condition range during stable operation; according to the method, suggestions and guidance are provided for safe and stable operation of the marine nuclear power system.

Owner:XI AN JIAOTONG UNIV

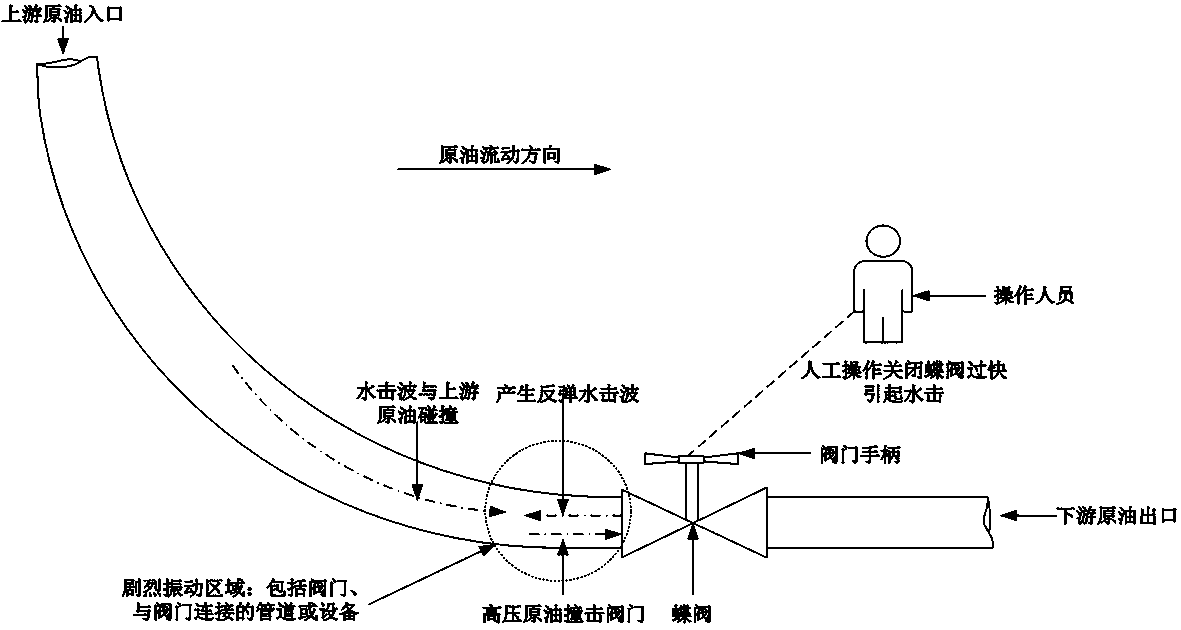

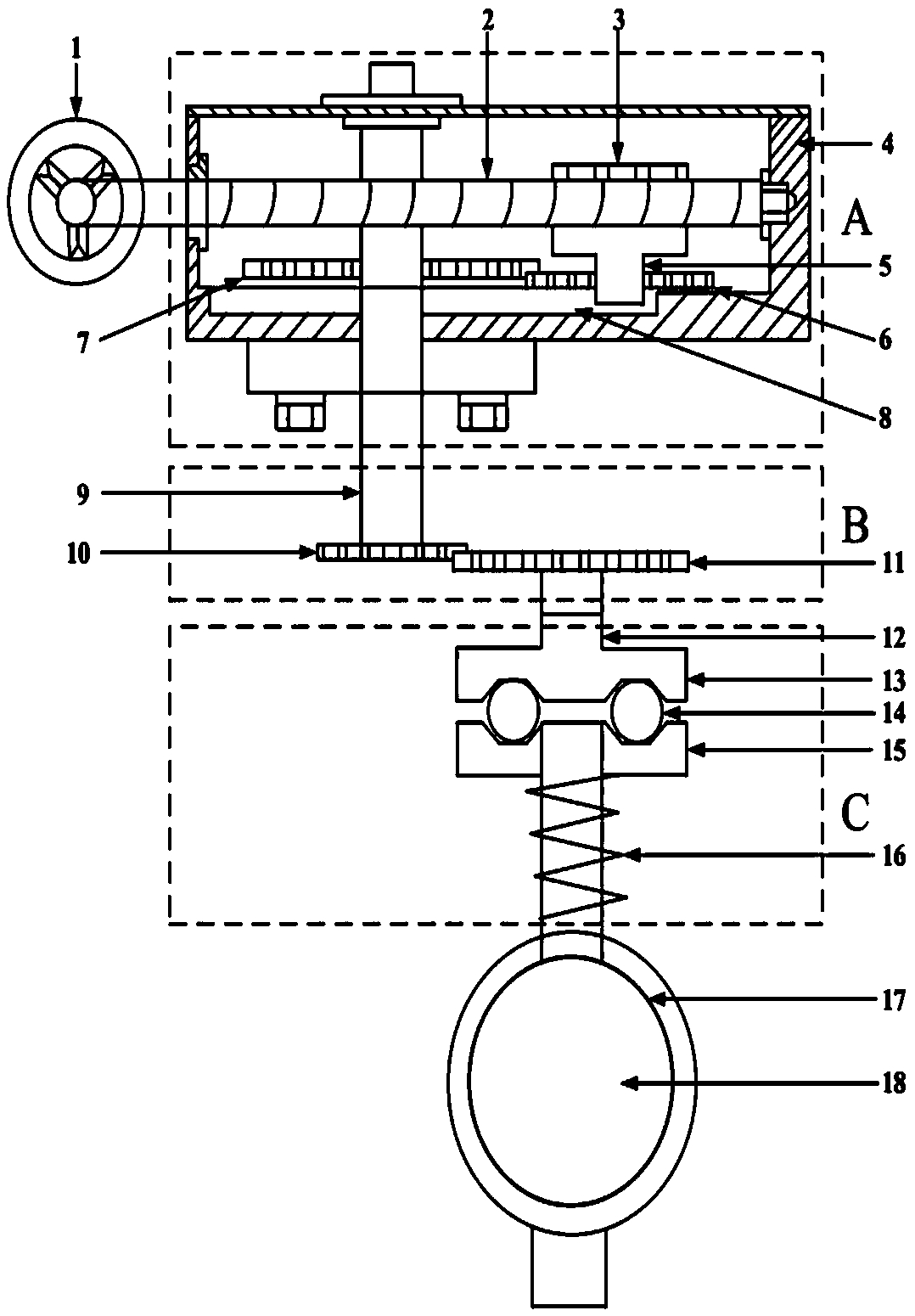

Water-resistant butterfly valve and method for low-lying position of large-fall oil conveying pipeline

ActiveCN109323008ALimit transmission speedControl off rateOperating means/releasing devices for valvesValve members for absorbing fluid energyRate limitingEngineering

The invention relates to a water-resistant butterfly valve and method for a low-lying position of a large-fall oil conveying pipeline. The butterfly valve is arranged at the low-lying risk pipe section of the pipeline, when the pipeline has dangerous working conditions such as leakage and the like, the butterfly valve plays a role in emergency shutdown of the accident pipe section, and is composedof a handle torque direction changing and dispersing unit, a valve rod gear transmission rate limiting unit and a valve rod torque magnitude control unit, aiming at the water hammer problem caused bythe sudden change of crude oil flow rate and pressure mutation in the pipeline caused by the quick closure of butterfly valve in low-lying position of oil pipelines by operators, the butterfly valveis designed according to the three aspects of the torque reduction of the butterfly valve handle, the limit of the transmission rate of the valve rod and the control of the transmission torque of thevalve rod, so that the force application of the operator to the handle can be reduced in the valve closing process, the rotating speed of the valve rod and the stress of the control valve rod are limited, the applicability of the butterfly valve at the low-lying position of the large-pipe-diameter oil conveying pipeline is improved, so that the valve closing rate is controlled within a reasonablerange to avoid the water hammer phenomenon, and the service life of the butterfly valve is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

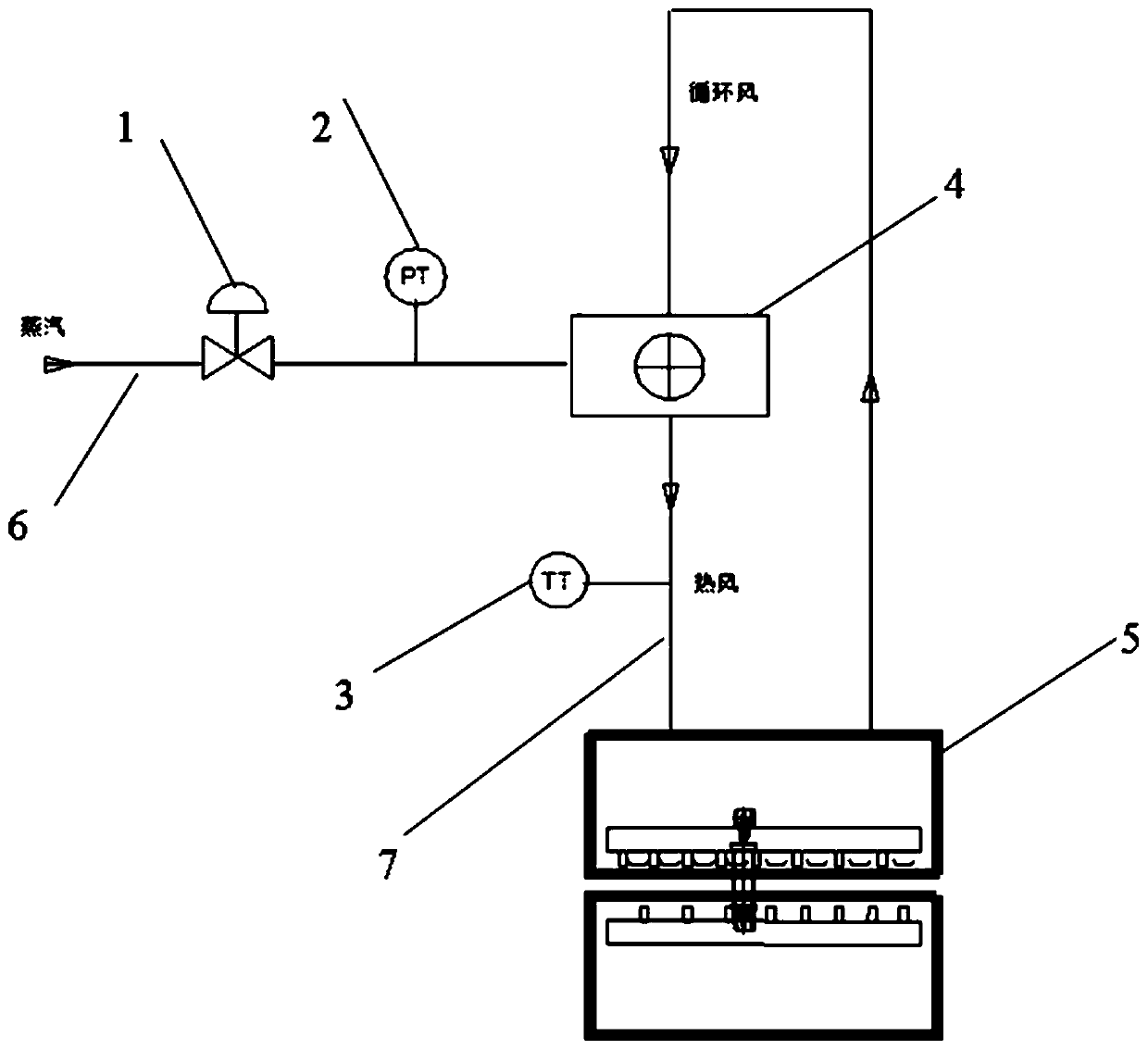

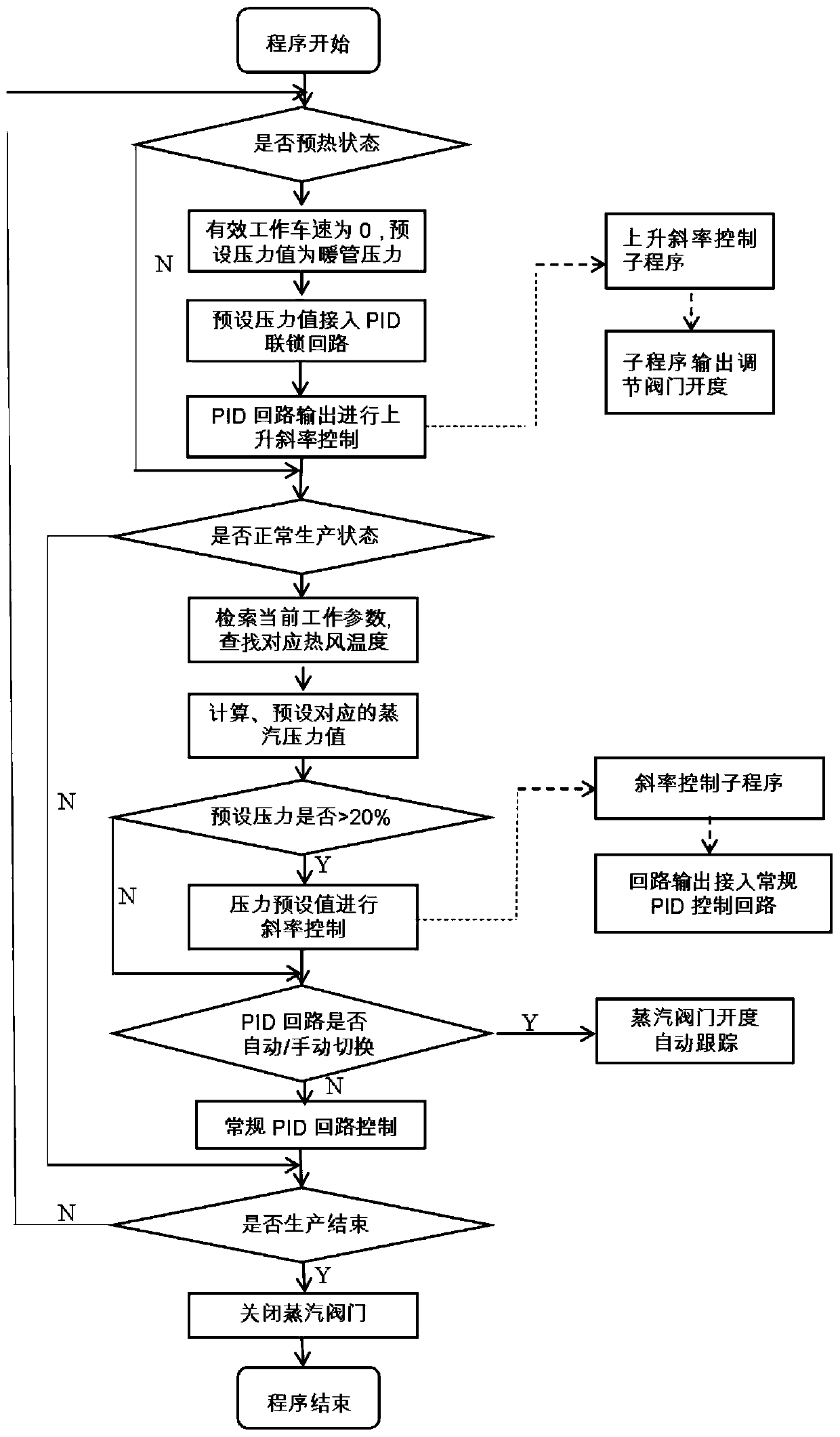

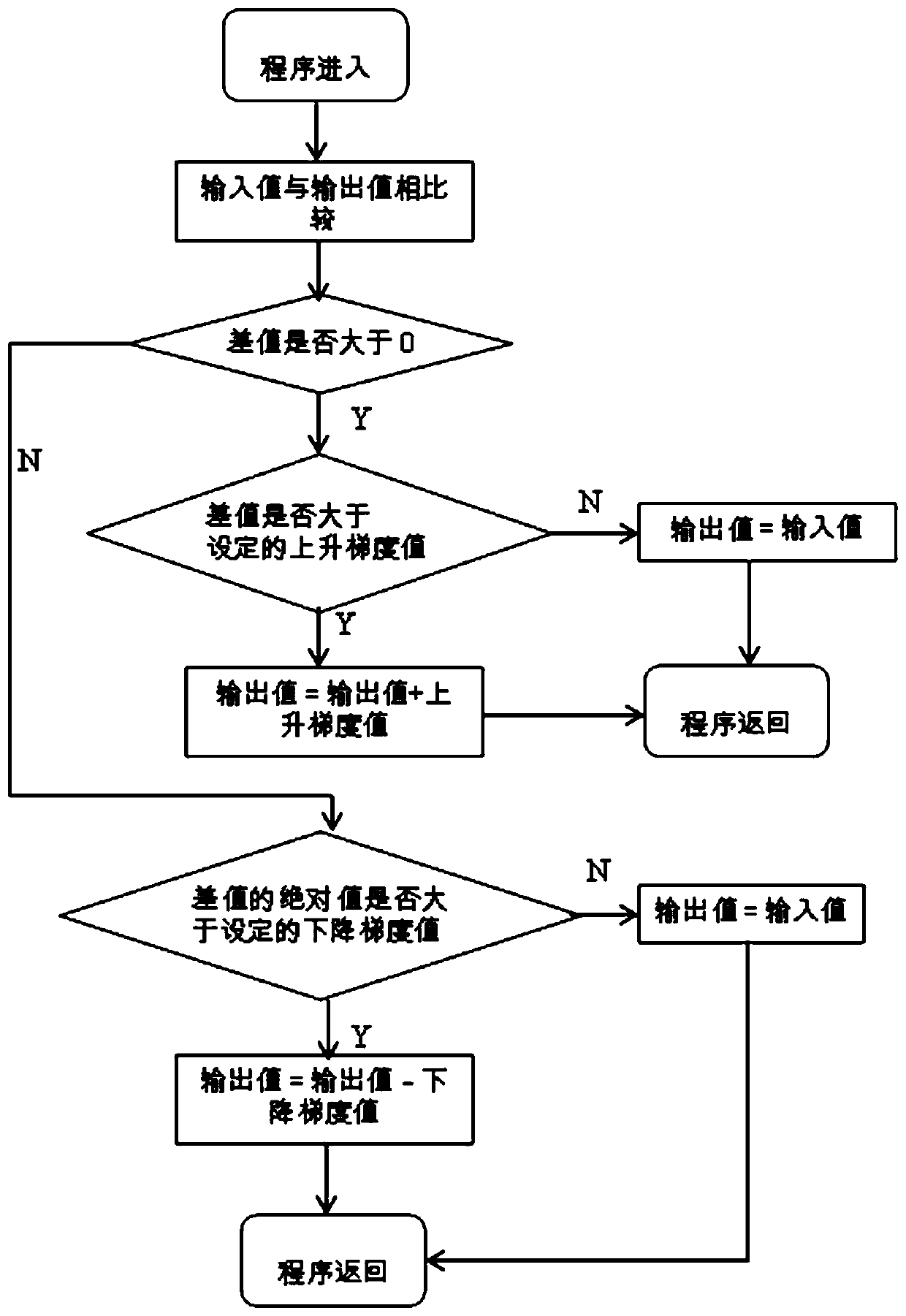

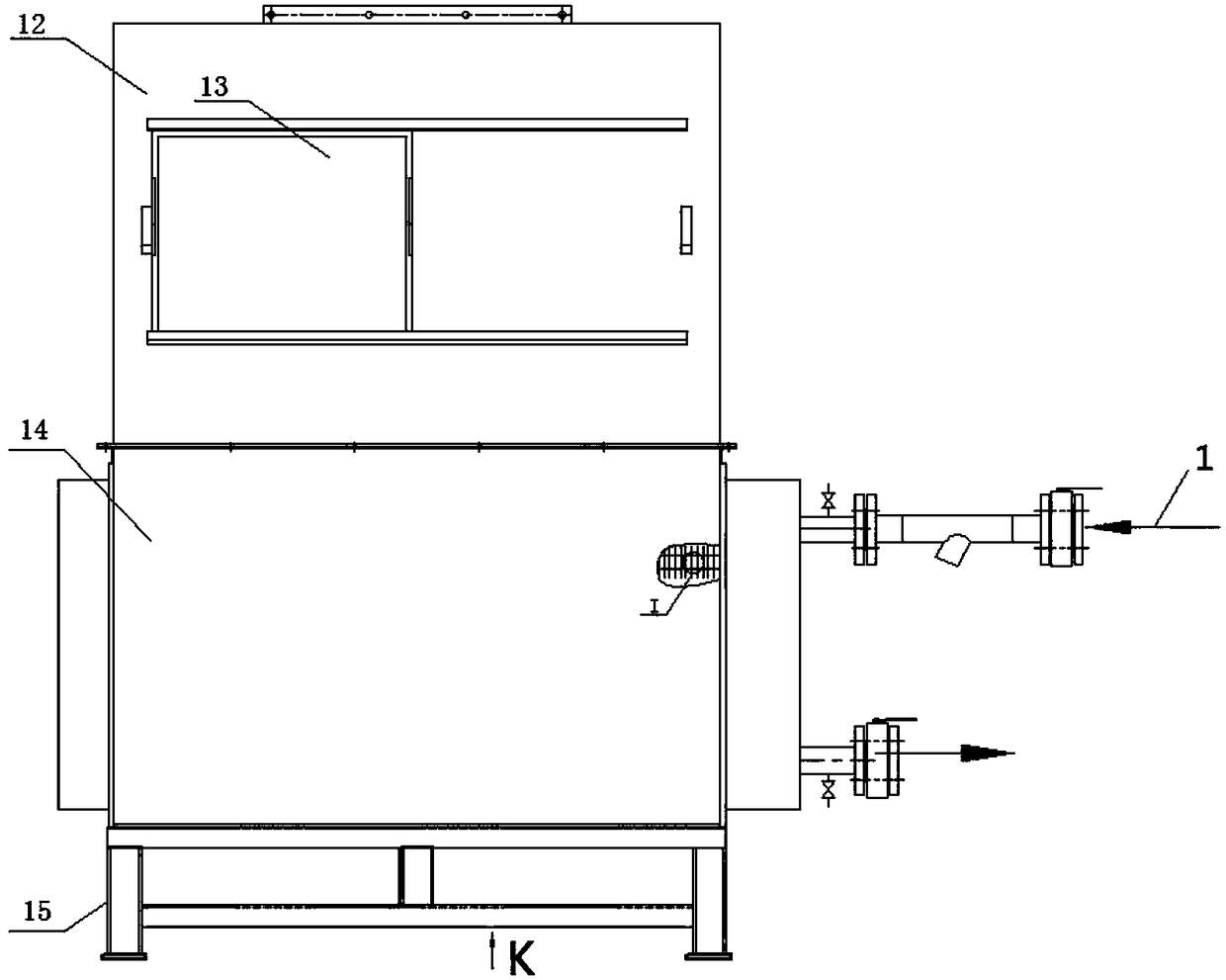

Heating control device and method of dying box for reconstituting tobacco by papermaking method

ActiveCN110720656AAvoid drastic changes in openingReduce drastic changesTobacco treatmentControl systemPapermaking

The invention discloses a heating control device and method of a drying box for reconstituting tobacco by a papermaking method. The heating control device includes a heat exchanger, a steam valve, a pressure meter, a hot air drying box, a temperature meter, a steam pipeline and a hot air pipeline. A control system receives detection signals of the on-site pressure meter and the temperature meter,reads the operating speed of a production system at the same time, automatically calculates a steam preset pressure value, and outputs the opening degree of the steam valve after through a PID interlocking control circuit composed of the pressure meter and the steam valve. During the production preheating phase, the situation of mechanical damage of heat exchanging equipment caused by water attackis prevented from occurring by controlling the rising slope of the opening degree of the steam valve; and during the production operating phase, the situation that heat exchanging quality is influenced due to phase state changing of the heat exchanger caused by drastic fluctuation of pressure is prevented from occurring by controlling the rising slope and the falling slope of preset parameters ofthe pressure, the smoothness of control is ensured, and the stability of the quality of heated paper sheets is ensured.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

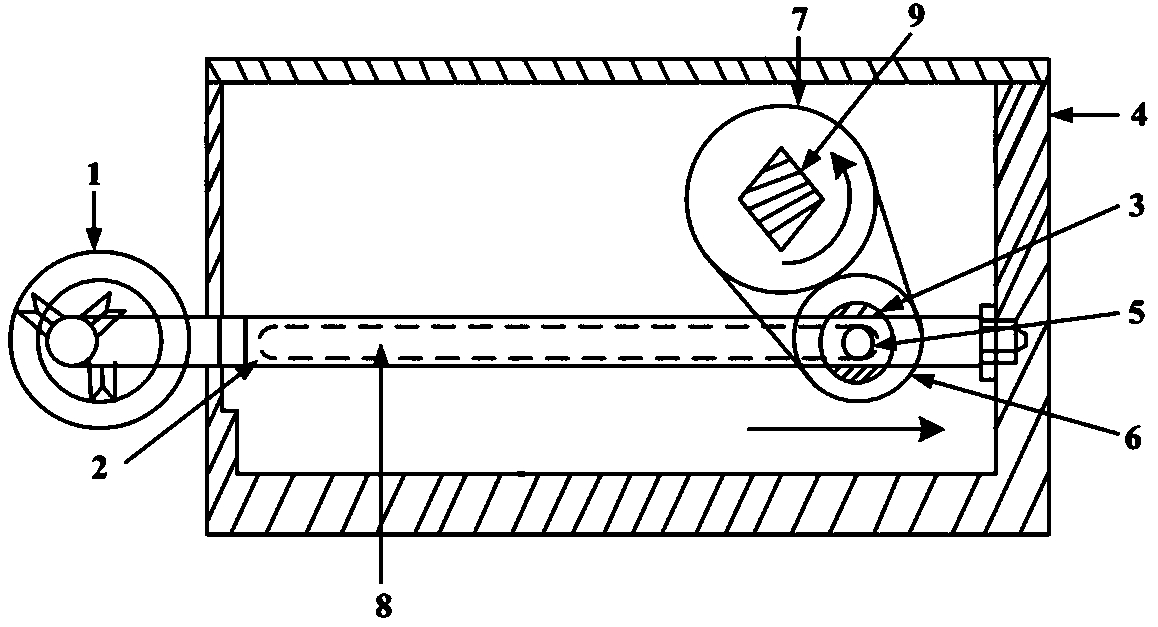

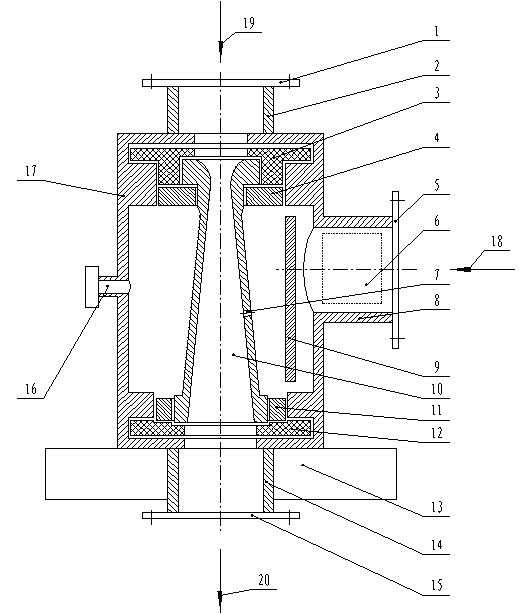

Wear-resistant and high-temperature-resistant butterfly valve made of full-forged steel material and manufacturing method thereof

ActiveCN112178221AAvoid wear and tearAvoid water hammerOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringButterfly valve

The invention discloses a wear-resistant and high-temperature-resistant butterfly valve made of a full-forged steel material. The butterfly valve comprises a pipeline, wherein a butterfly valve body is arranged inside the pipeline; and a box body is fixedly arranged at the top of the pipeline, a transmission cavity and a working cavity located below the transmission cavity are formed inside the box body, and a first rotating shaft penetrating through the pipeline and the bottom of the working cavity is arranged at the top of the butterfly valve body. The wear-resistant and high-temperature-resistant butterfly valve made of the full-forged steel material has the beneficial effects that the butterfly valve is simple in structure and easy and convenient to operate, the rotating speed of a butterfly valve plate can be automatically adjusted according to the current water pressure in the pipeline when people open the valve, so that the water hammer phenomenon caused by too large instantaneous change of pressure inside the pipeline due to too high opening speed of the butterfly valve plate is avoided, pipeline interior bursting and butterfly valve plate abrasion can be prevented, simplicity and efficiency are achieved, convenience and rapidness are achieved, and the practicability is high.

Owner:GUOGONG HLDG GRP CO LTD

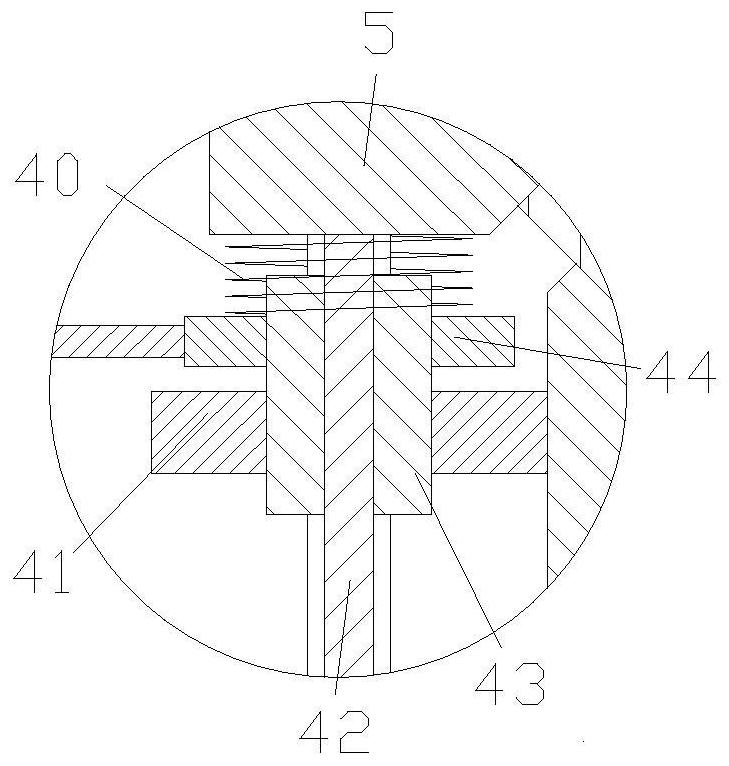

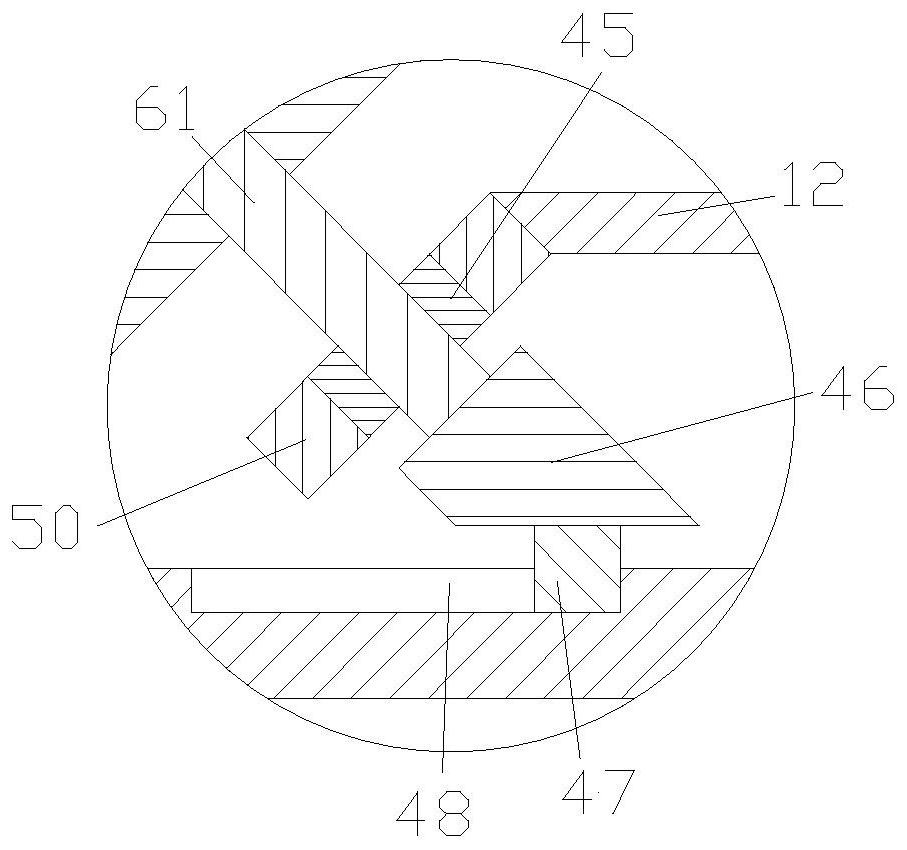

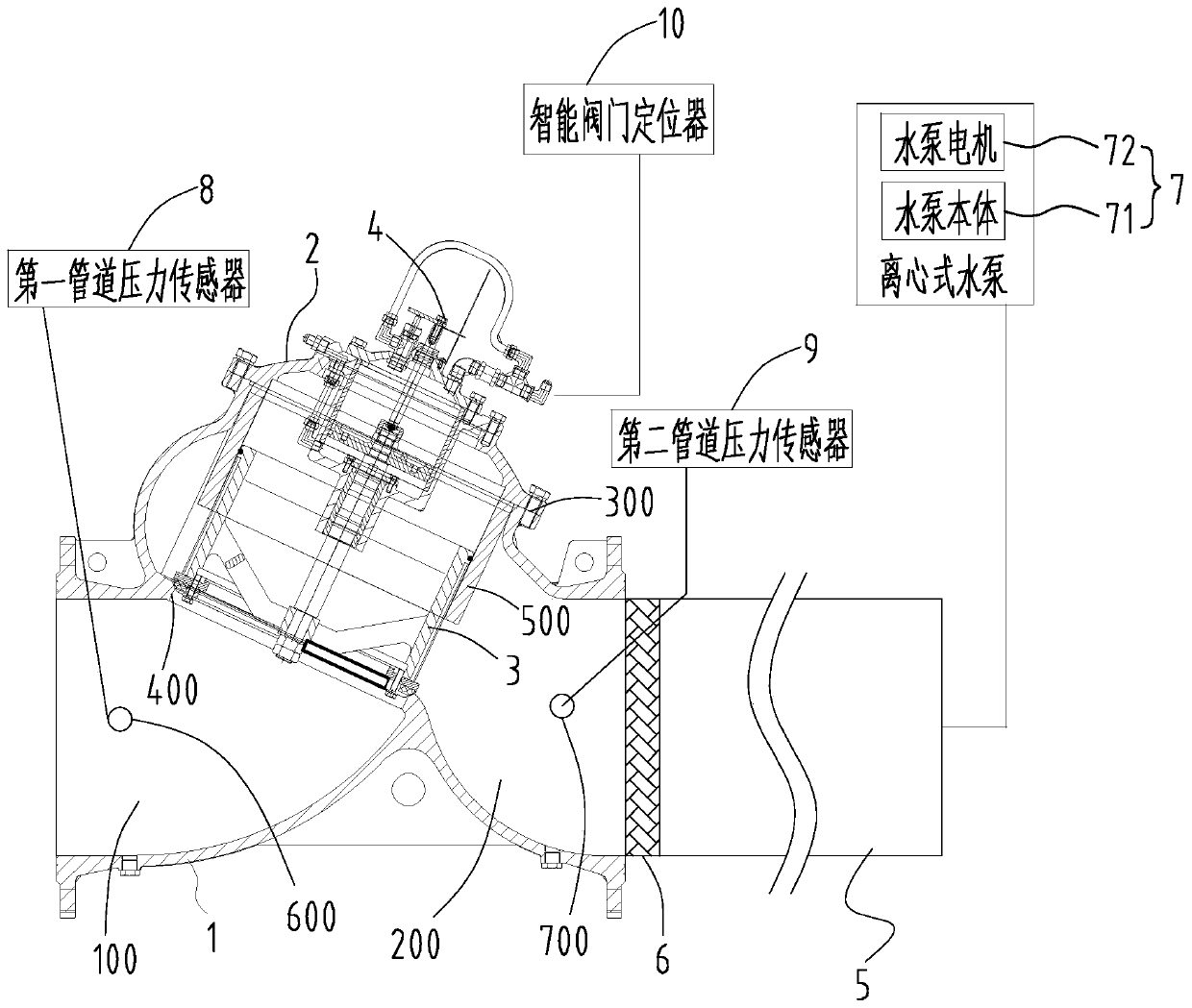

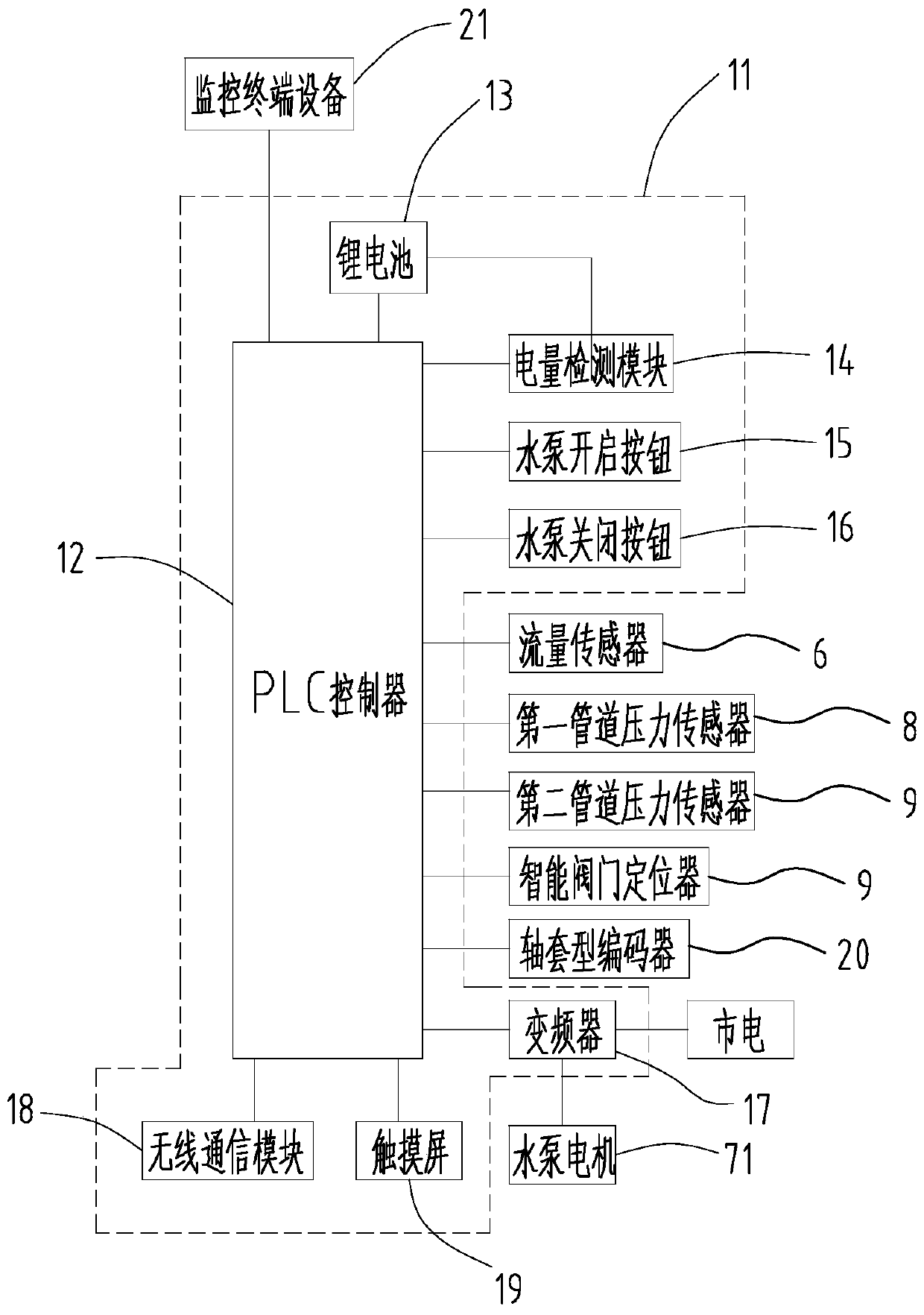

Intelligent water pump control valve system and control method thereof

ActiveCN110905829AAvoid water hammerAvoid it happening againPump controlNon-positive displacement fluid enginesElectric machineryTransverter

The invention relates to an intelligent water pump control valve system, which comprises a vortex-free water pump control valve, monitoring terminal equipment, a water outlet pipeline, an intelligentvalve positioner, a centrifugal water pump, a first pipeline pressure sensor, a second pipeline pressure sensor, a shaft sleeve type encoder, a flow sensor and a controller. The vortex-free water pumpcontrol valve is connected with the intelligent valve positioner; the centrifugal water pump comprises a water pump body and a water pump motor; the shaft sleeve type encoder sleeves a main shaft ofthe water pump motor; the vortex-free water pump control valve is connected with the centrifugal water pump through the flow sensor and the water outlet pipeline in sequence; the first pipeline pressure sensor and the second pipeline pressure sensor are installed on the vortex-free water pump control valve; the controller comprises a PLC, a lithium battery, an electric quantity detection module, afrequency converter, a water pump starting button, a water pump stopping button and a wireless communication module, and all electronic components are connected in a matched mode. The problem that the water pump control valve is suddenly opened or closed to generate the water hammer effect is solved.

Owner:沪航科技集团有限公司

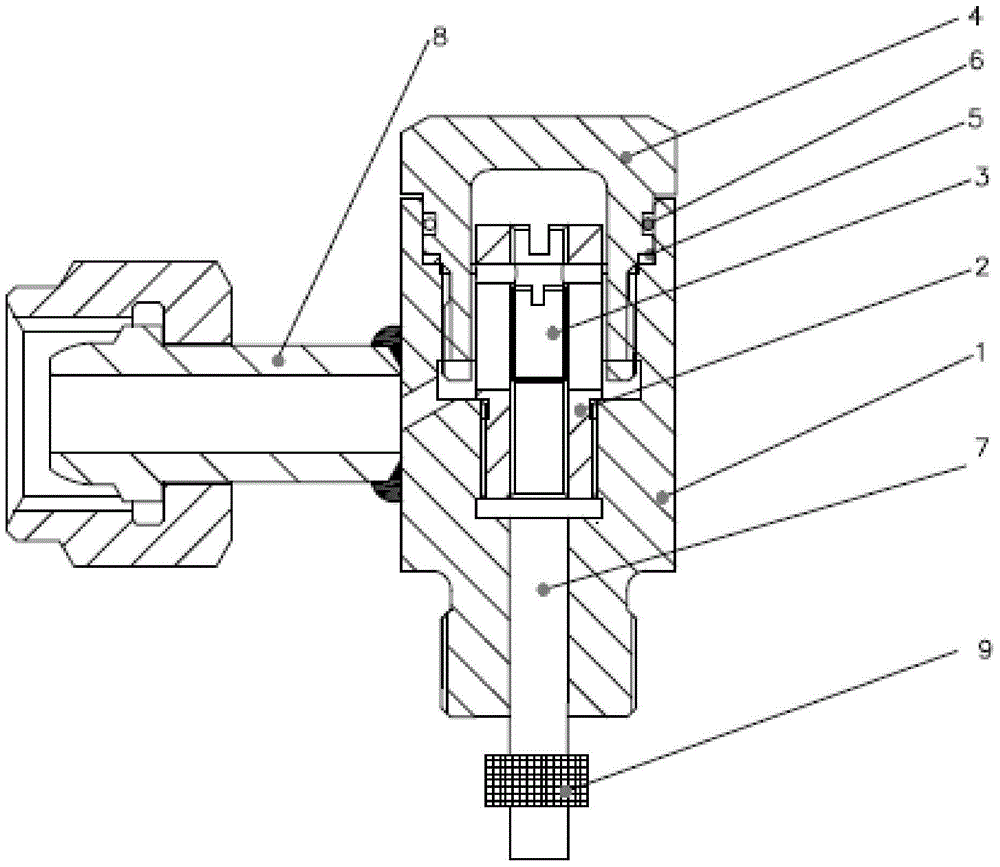

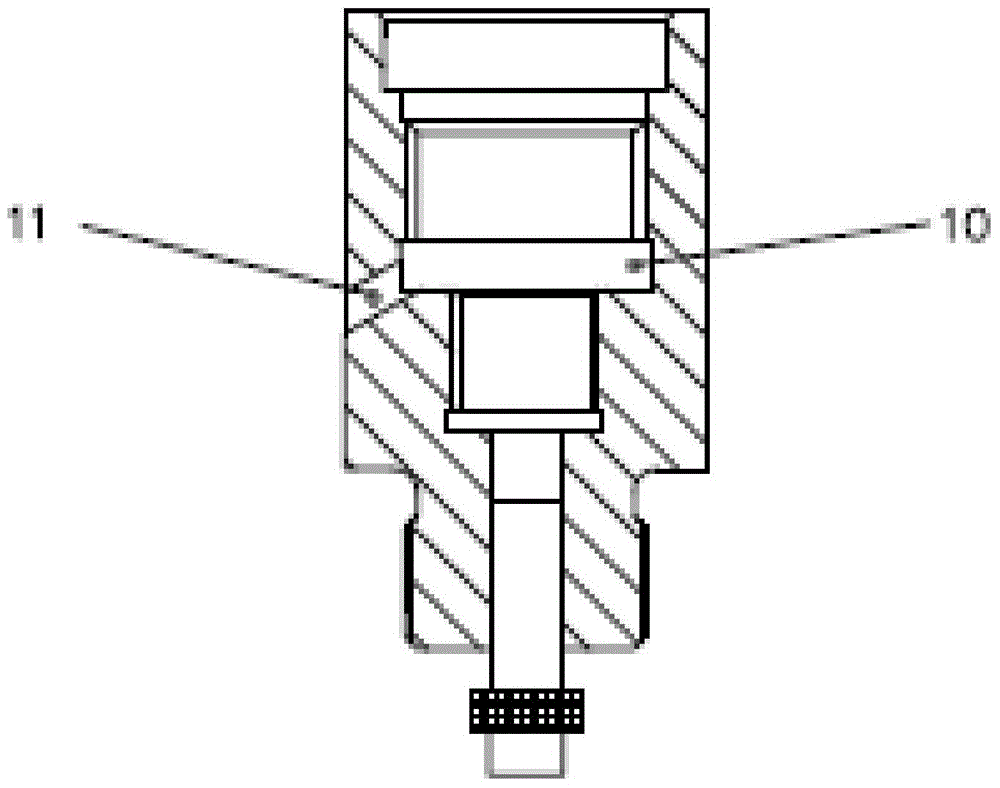

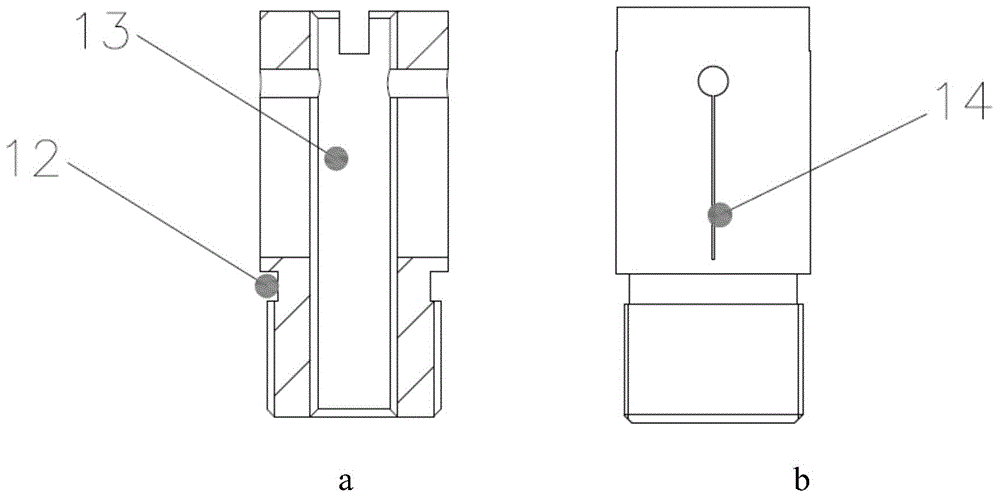

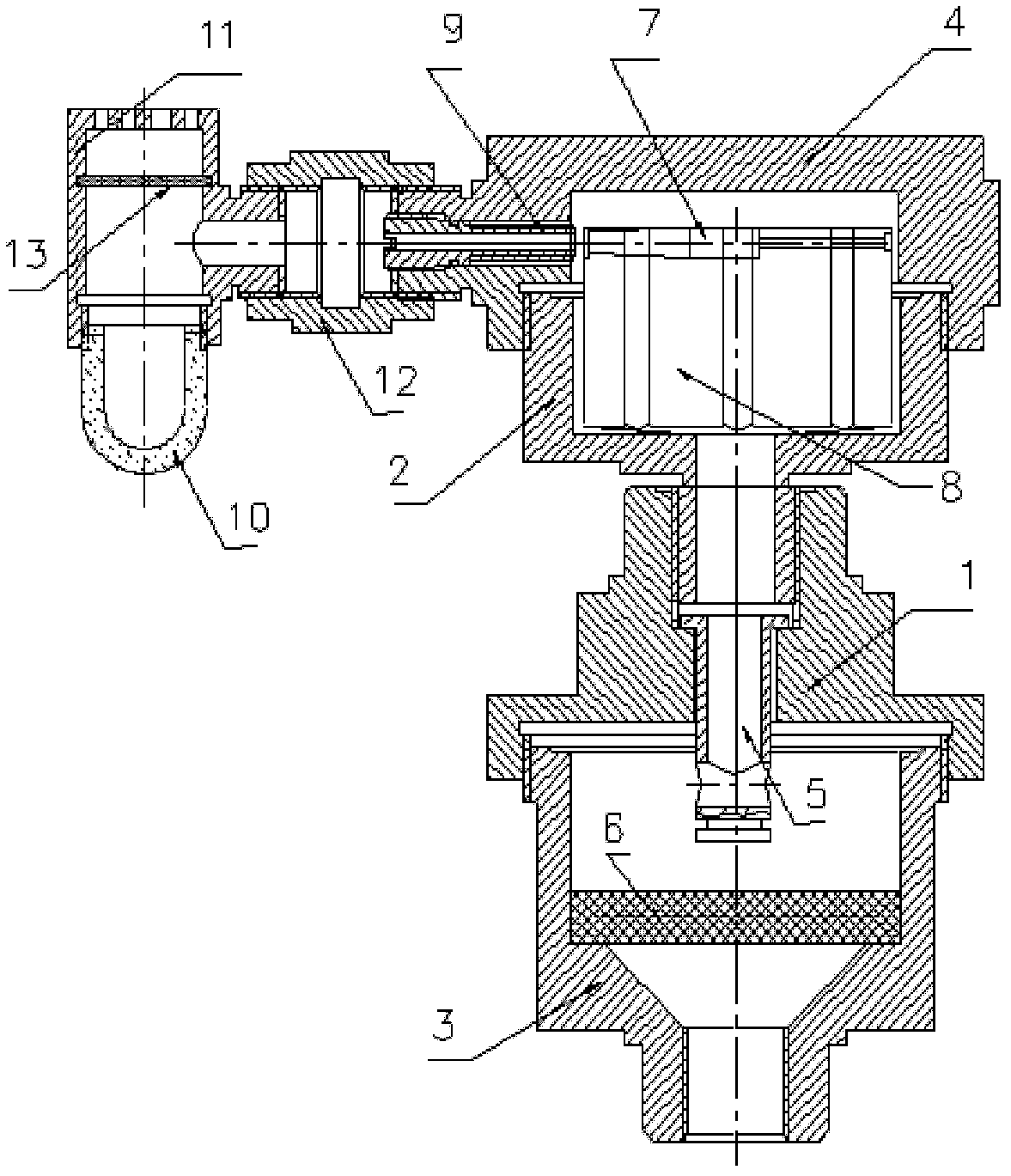

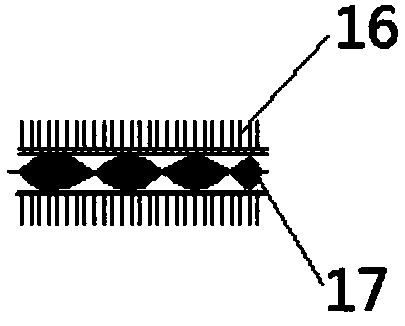

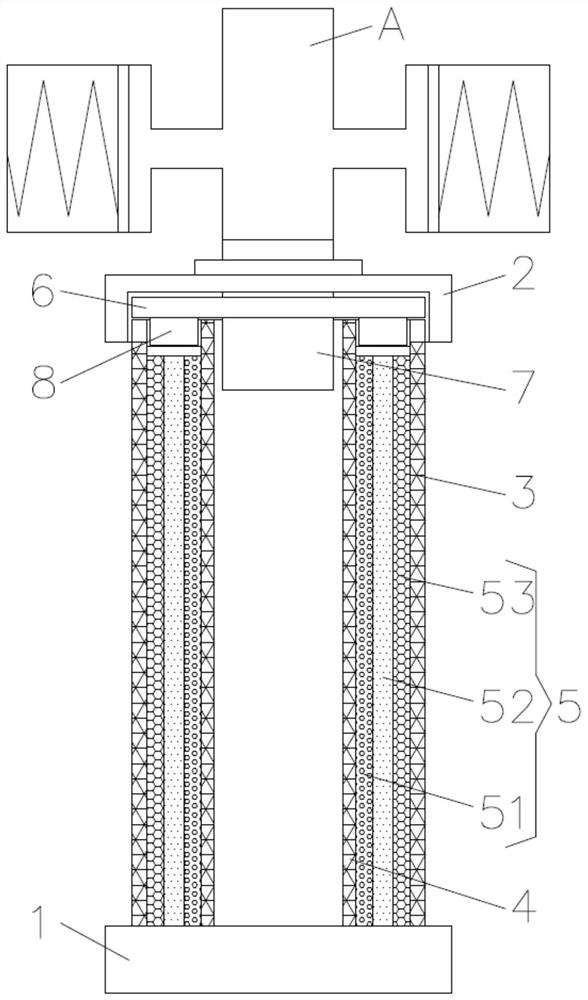

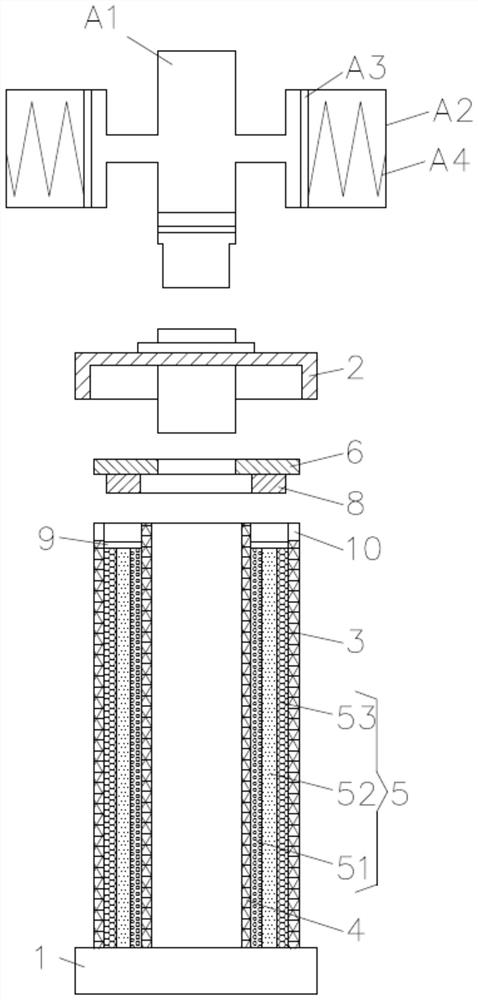

Automatic exhaust valve of heating medium oil system

ActiveCN103161994ASolve the failure of circulation pump pumping out and severe vibrationImprove pump efficiencyOperating means/releasing devices for valvesLiquid degasificationExhaust valveHydrocarbon

The invention discloses an automatic exhaust valve of a heating medium oil system. The valve is composed of a lower valve body (1), an upper valve body (2), a valve base (3), a valve cover (4), a flow guide body (5), a filtering net (6), an adjusting polish rod (7), an air floater (8), an adjusting screw rod (9), an air-permeable valve cover (11), a tee joint (12) and a filtering net (13), wherein the valve base, the lower valve body, the upper valve body, the valve cover, the tee joint and the air-permeable valve cover are sequentially in threaded connection, the filtering net (6) is arranged on a cone on the lower portion of an inner cavity of the valve base, the flow guide body is installed in inner holes which are formed in the lower valve body and the upper valve body, two sides of the flow guide body are provided with openings, the air floater is arranged in the upper valve body, the adjusting polish rod is installed in a concave groove in the upper portion of the air floater, the adjusting screw rod is installed in an inner screw hole in the valve cover, and the filtering net (13) is arranged in a groove in the inner wall of the air-permeable valve cover. The exhaust valve can effectively remove free steam generated in an inlet pipe section of a heating medium pump and hydrocarbon vapor in heating medium oil, and guarantees normal operation of the heating medium oil system.

Owner:PETROCHINA CO LTD

Circulating pump pipeline

InactiveCN105972672ACushion the shockExtended service lifeLighting and heating apparatusHot-water central heatingStopped workWater flow

The invention discloses a circulation pump pipeline, which includes a water inlet tee and a water outlet tee installed on the circulation pipeline, and a circulation pump and a bypass pipe are respectively connected between the water inlet tee and the water outlet tee. The connecting pipe between the circulation pump and the water inlet tee is provided with a direct-acting solenoid valve, and the connecting pipe between the direct-acting solenoid valve and the water inlet tee is provided with a pressure relief valve. A one-way valve is arranged on the through pipe. When the circulation pump stops working suddenly, part of the water flows out from the bypass pipe, which alleviates the impact of the water flow on the circulation pump, thereby avoiding the occurrence of water hammer and water hammer, and prolonging the service life of the circulation pump. The invention has a simple structure and Strong reliability.

Owner:天津地热开发有限公司

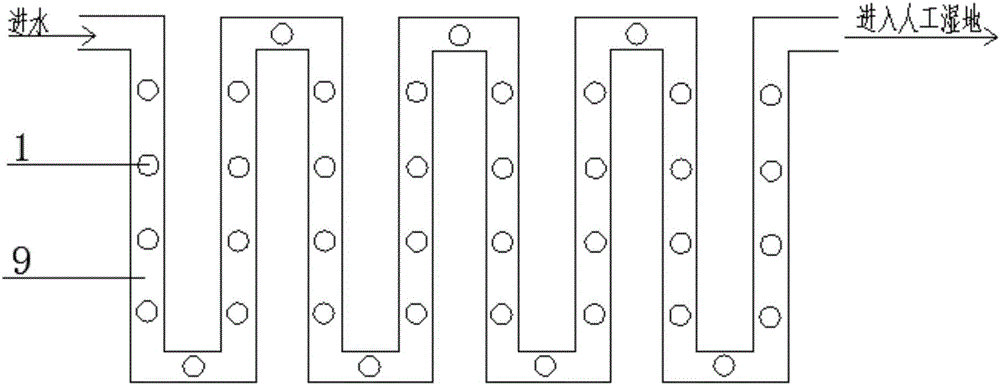

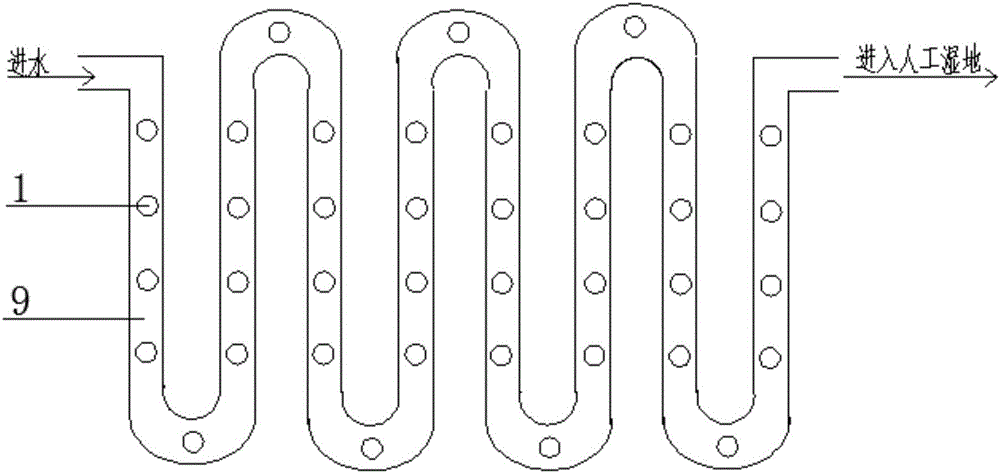

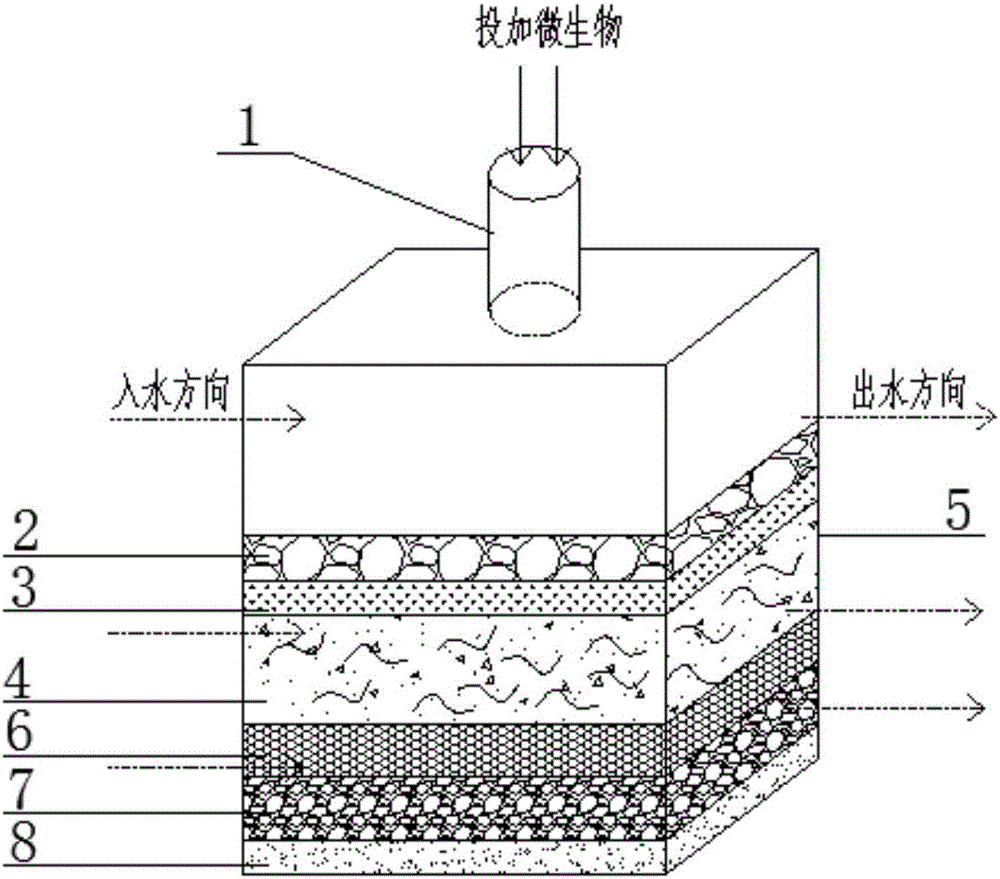

Incoming water pretreatment device for constructed wetland system and method thereof

InactiveCN106430613AImprove water qualityAvoid water hammerTreatment using aerobic processesSustainable biological treatmentPre treatmentPollutant

The invention relates to a water inlet treatment device for a constructed wetland system and a method thereof, and particularly relates to an incoming water pretreatment device for a constructed wetland system and a method thereof. The device comprises a square pipeline, wherein a filling layer is arranged at the bottom of the square pipeline, and is two thirds as high as the square pipe; the filling layer is divided into a physical filter layer and an earthworm filter layer from bottom to top; a round vent is formed right above the square pipeline. According to the method, after the device is applied to a grating and a grit chamber, sands and large particles in sewage are removed, and the sewage enters a sewage delivery pipeline of the device and flows through the earthworm filter layer and the physical filter layer in the delivery process, so that organic matters and solid pollutants in the sewage are further purified.

Owner:星景生态环保科技(苏州)有限公司

A large-scale negative pressure heating furnace air preheating system and method

ActiveCN106196145BSolve traffic distribution problemsAvoid water hammerCombustion processIndirect carbon-dioxide mitigationReducerHeating furnace

Owner:北京联创鼎新石化设备有限公司

Emergency cut-off valve for water conveying pipeline

InactiveCN114382906AReduce transfer volumeAvoid negative pressureOperating means/releasing devices for valvesValve members for absorbing fluid energyStructural engineeringWater hammer

The invention relates to the technical field of remote water delivery equipment, and discloses an emergency cut-off valve for a water delivery pipeline, the emergency cut-off valve comprises a valve body, a middle column is fixedly mounted in the valve body, a V-shaped nozzle is fixedly mounted in the center of the right part of the middle column, a rubber water bag is movably mounted in the V-shaped nozzle, and the left end of the rubber water bag is fixedly connected with a water pipe; a fixed box is fixedly installed above the valve body, a cut-off plate is movably installed in the fixed box, and the cut-off plate is movably connected with the valve body. Through the arrangement of the rubber water bag and the cut-off plate, when the internal transmission pressure of the valve body is too large, water is slowly filled into the rubber water bag, the rubber water bag is gradually expanded, a channel of the valve body is gradually closed, the water transmission amount is reduced, the water hammer effect caused by rapid cut-off is avoided, the channel of the valve body is slowly closed, and negative pressure of a subsequent transmission pipeline is avoided; and a vacuum effect occurs, and the transmission pipeline is effectively protected.

Owner:陈一铭

Pipeline-type mixed heating equipment

ActiveCN102162702BAvoid outgoingAvoid direct contactDirect contact heat exchangersLow noiseEngineering

The invention discloses heating equipment for directly heating liquid, and relates to steam direct (mixed) heating equipment with a brand-new structure and performance, solving the problems of vibration, water impact, air impact and noise in the operation process of the heating equipment; vibration elimination devices are arranged at the two ends of an inner core for eliminating the vibration forthe first time and preventing the vibration conduction; steam silencers are arranged on the outer periphery and the outer side of the outlet of the inner core, thus comprehensively absorbing and eliminating the noise; a water impact-resisting device and an air impact-resisting device are arranged at the steam inlet, thus preventing the water impact appears when the equipment is started; and a seal device between the two ends of the inner core and a shell is tightly combined with the inner core, the shell and a vibration prevention device, and the structure is also created for the first time. By the four originations, the quiet stable operation without air impact, vibration and noise or in low noise is comprehensively realized for the first time in the world. The equipment can be widely applied to heat various process-used water and life-used water.

Owner:湖南一公喷射器制造有限公司

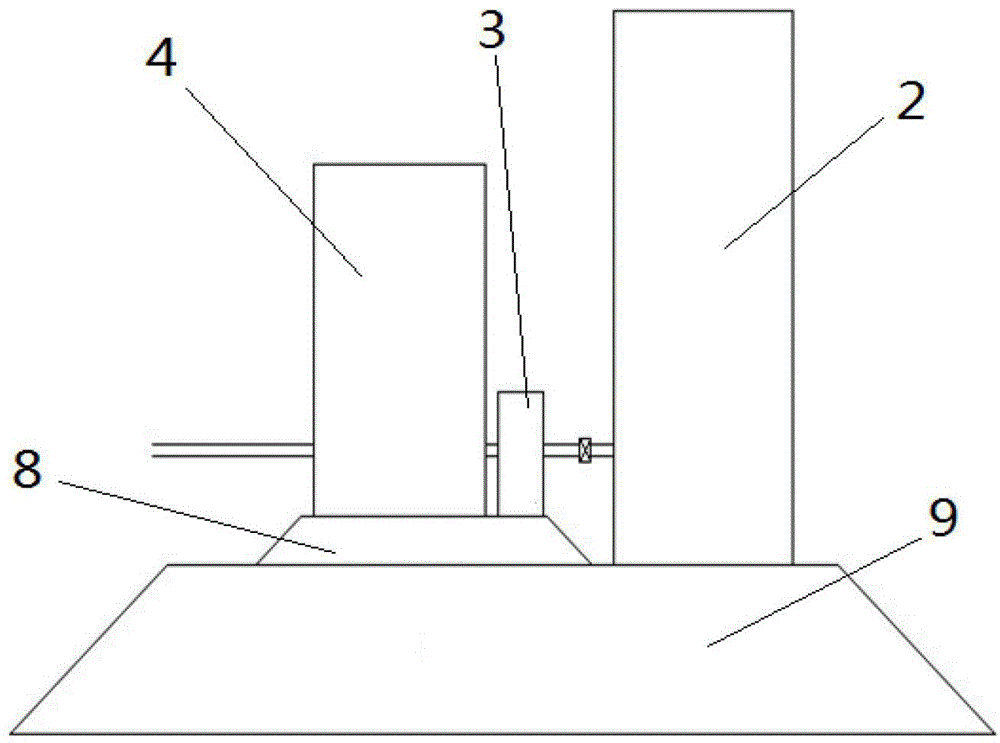

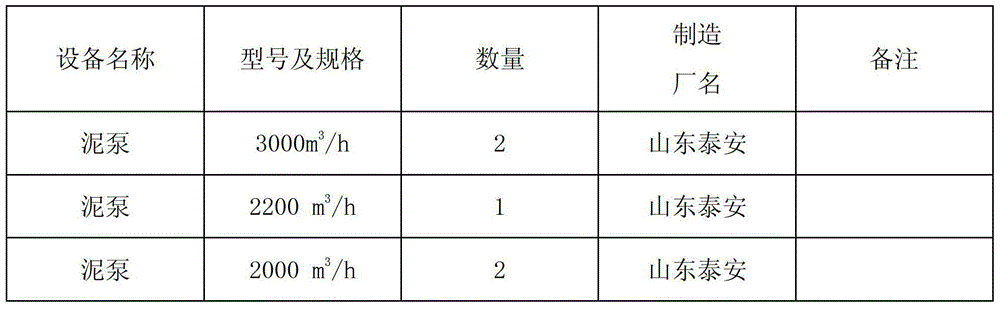

An open-type slurry tank relay blow-fill pumping station system and its construction method

ActiveCN103266642BRealize long-distance dredging and filling operationsSimple and fast operationSoil-shifting machines/dredgersLine tubingSludge

The invention relates to an open-type slurry collecting pool relay reclamation pump station system and a construction method of the system, belonging to the technical field of dredging engineering. The open-type slurry collecting pool relay reclamation pump station system comprise an open-type slurry collecting pool and a relay pump station; a land sludge discharge pipeline of a cutter suction dredger is built at the top of the slurry collecting pool in an extending way; the slurry collecting pool is connected with a suction pipe of the relay pump station; and the dredged material is conveyed into a specified reclamation area by a polyvinyl chloride (PVC) which is in standard equipped on the relay pump station. According to the construction method of the open-type slurry collecting pool relay reclamation pump station system, the open-type slurry collecting pool relay pump station is built, the relay pump station and the cutter suction dredger are used for joint construction; the open-type slurry collecting pool is used for middle transfer, the cutter suction dredger and the pump station are matched in flow rate, the cutter suction dredger is used for reclaiming the dredged material into the slurry collecting pool, and a dredge pump of the relay pump station is used for reclaiming the dredged material from the slurry collecting pool into a sludge containing area, thus completing the reclamation operation. The open-type slurry collecting pool relay reclamation pump station system has the advantages of simple structure, high applicability, high reclamation time utilization rate, high production efficiency, and is suitable for long-distance reclamation land building construction, etc.

Owner:CCCC TDC BINHAI ENVIRONMENTAL CHANNEL DREDGING

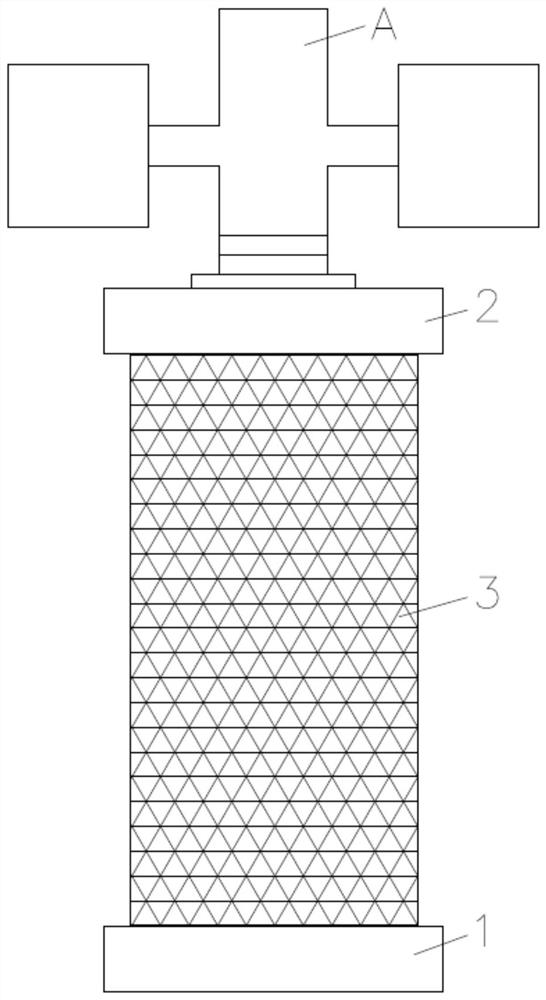

Filtering device with water hammer eliminating device

InactiveCN112569670AImprove filtering effectImprove purification effectTreatment involving filtrationMultistage water/sewage treatmentEngineeringWater hammer

The invention discloses a filtering device with a water hammer eliminating device. The filtering device comprises a filtering unit and a plurality of water hammer eliminating units, wherein each waterhammer eliminating unit comprises a connecting pipe, a cylindrical piston cavity, a piston and an elastic piece; the two ends of the elastic piece abut against the bottom of the cylindrical piston cavity and the face, opposite to the piston, of the elastic piece respectively, the stroke of the piston is limited in the cylindrical piston cavity, and a water inlet of the cylindrical piston cavity is communicated with the connecting pipe; a water inlet of the cylindrical piston cavity is installed on a connecting pipe through threads, and the connecting pipe is connected with a water inlet pipeof the filtering unit through threads. The invention aims to provide the filtering device with the water hammer eliminating device, and the filtering device can slow down the impact of high-pressure liquid and has a certain protection effect on a pipeline and a filter.

Owner:佛山市顺德区盈沣泰环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com