Anti-theft intelligent air release valve

An anti-theft, exhaust valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as damage to the outer surface of the float, pipeline vacuum, exhaust port leakage, etc., to improve water supply efficiency and protect pipeline safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure of the anti-theft intelligent exhaust valve of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0015] The anti-theft intelligent exhaust valve is a structure with a major breakthrough in the technical field.

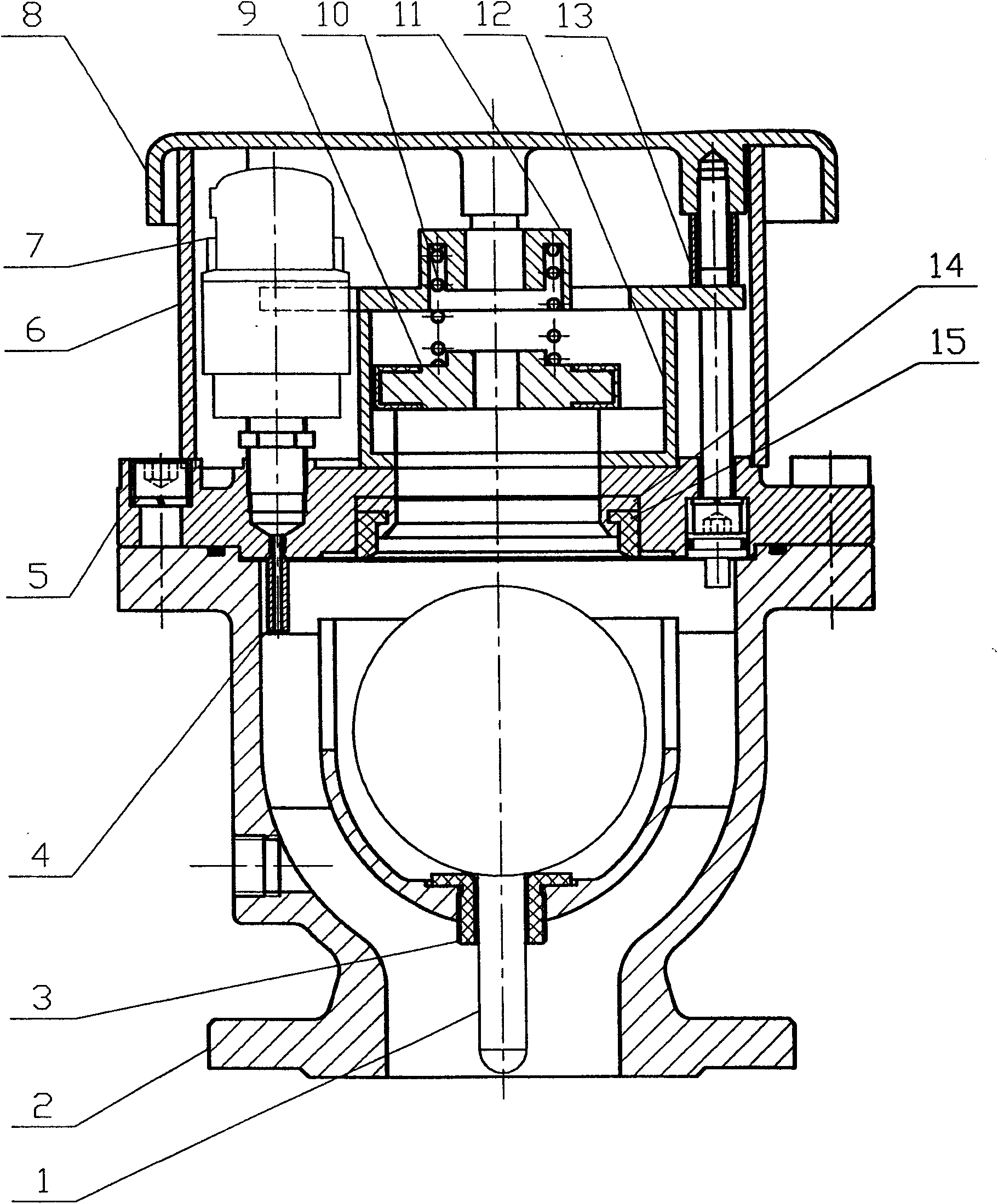

[0016] Such as figure 1 As shown, the anti-theft smart exhaust valve adopts a protective assembly, and all detachable parts are built into the protective cover (6), and the bolts connected to the valve body (2) are sunk into the outer peripheral boss of the casing (5) by hexagon socket bolts Inside, the upper part of the bolt is blocked and cannot be removed without special tools.

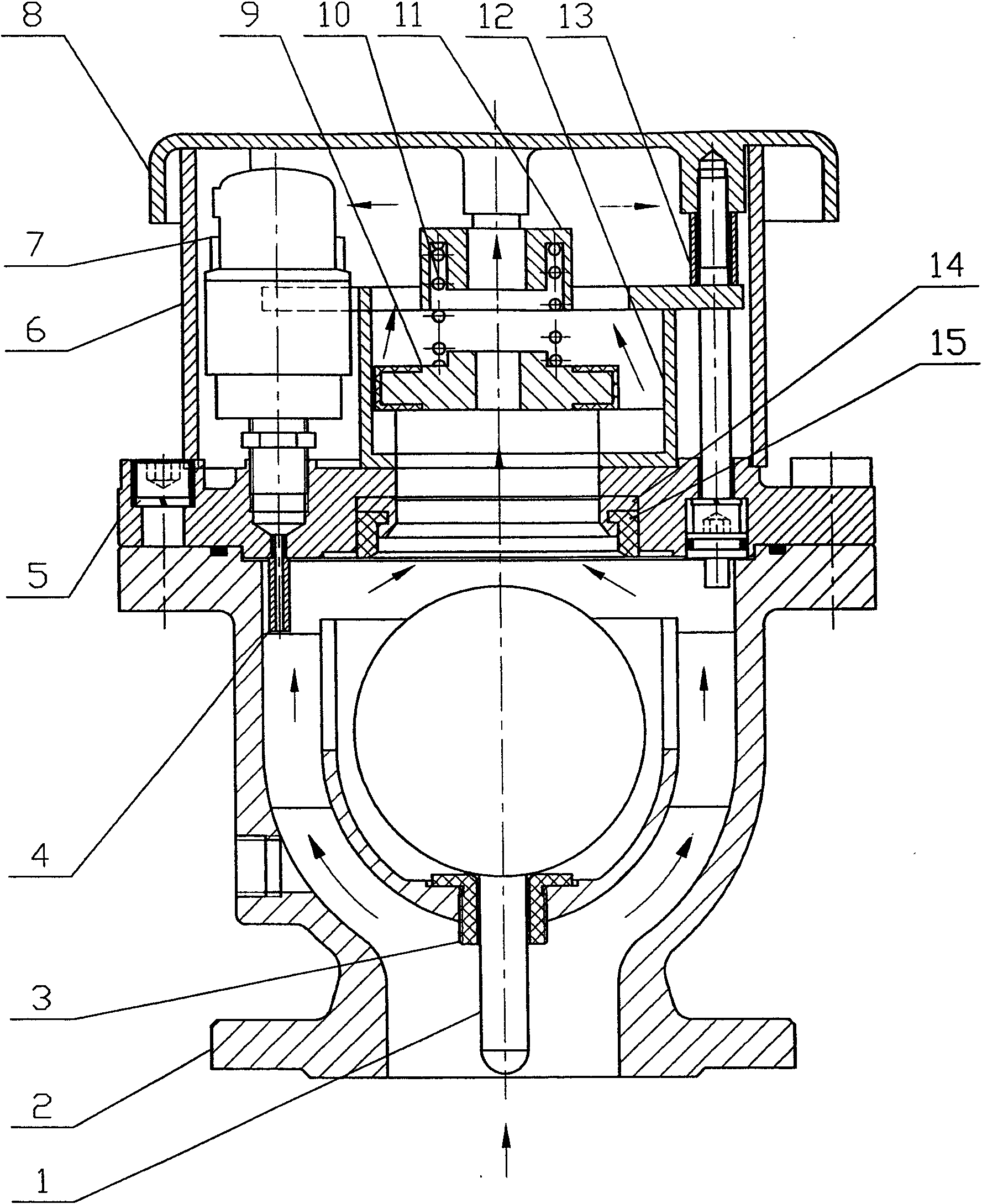

[0017] Such as figure 2 as shown, figure 2 The middle arrow indicates the direction of air flow. When the pipeline is initially filled with water, the pressure in the pipeline is low, and a large number of intake and exhaust valves and a small amount of intake and exhaust valves discharge the air in the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com