Plant irrigation platform for rock ecological restoration

An ecological restoration and plant technology, applied in the fields of botany equipment and methods, application, horticulture, etc., can solve the problem of single function of plant irrigation platform, and achieve the effect of realizing flow, realizing regulation and preventing water hammer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

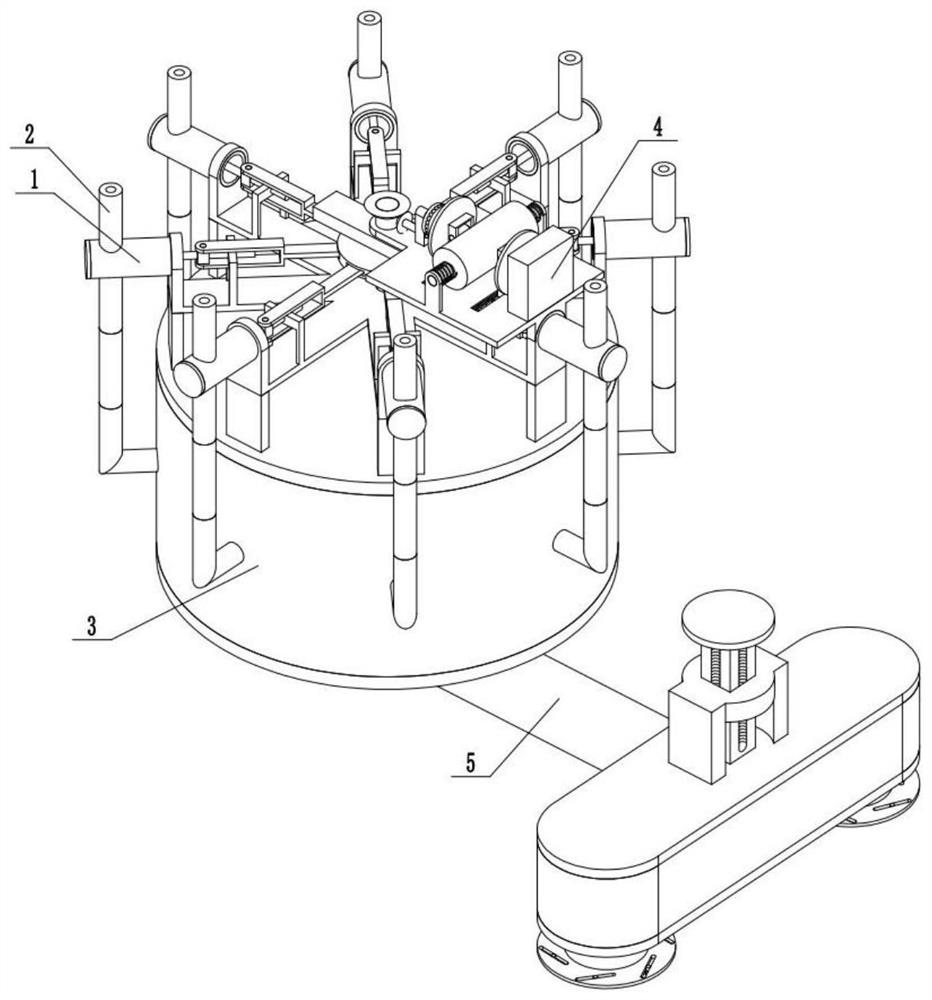

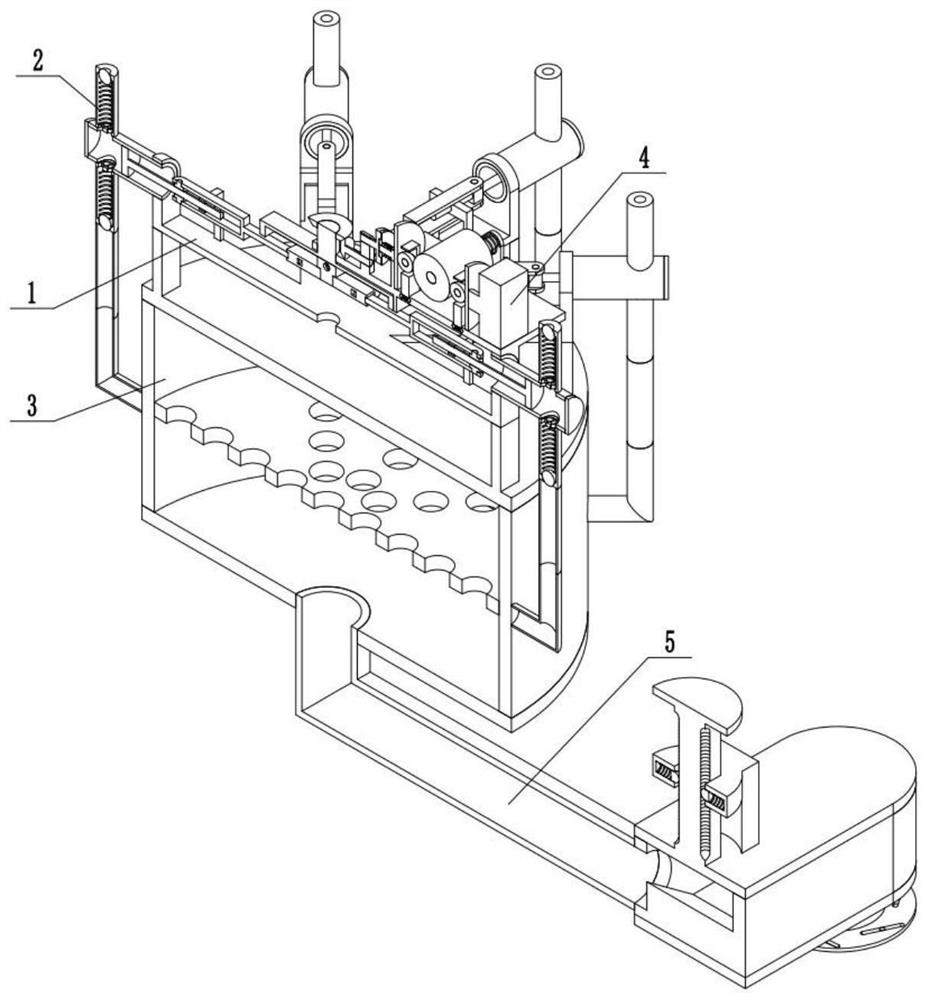

[0034] Combine below Figure 1-16 Description of this embodiment, a plant irrigation platform for rock ecological restoration, including a gas booster assembly 1, a one-way valve assembly 2, a water tank assembly 3, a power assembly 4, and a spout assembly 5, the gas booster The valve assembly 2 is connected, the one-way valve assembly 2 is connected with the water tank assembly 3 , the gas booster assembly 1 is connected with the power assembly 4 , and the spout assembly 5 is connected with the water tank assembly 3 .

specific Embodiment approach 2

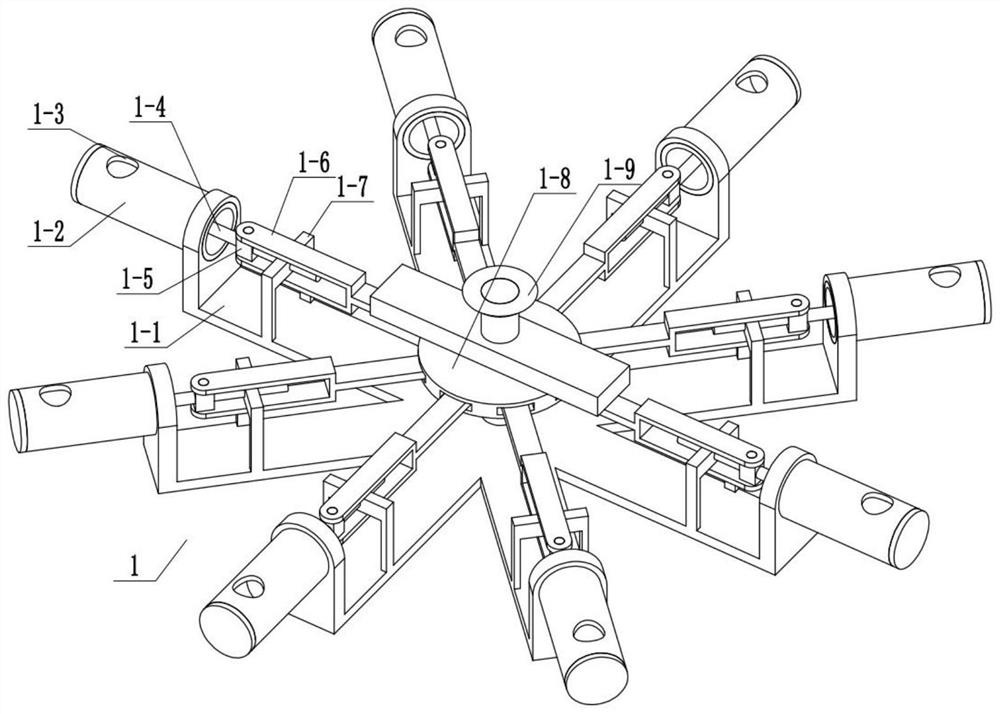

[0036] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain the first embodiment, the gas booster assembly 1 includes a booster bracket 1-1, a cylinder 1-2, a mounting hole 1-3, a piston rod 1-4, and a hinged terminal 1-5, hinged rotating rod 1-6, auxiliary bracket 1-7, eccentric drive plate 1-8, bevel gear 1-9, drive terminal 1-10, spherical clamping rod 1-11, spherical clamping rod push spring 1 -12, drive turret 1-13, spherical card slot one 1-14, installation hole two 1-15, the cylinder 1-2 is fixedly connected with booster support 1-1, installation hole one 1-3, installation hole Both 1-15 are arranged on the cylinder 1-2, the piston rod 1-4 is slidingly connected with the cylinder 1-2, the inner end of the cylinder 1-2 is hollowed out, and the hinged terminal 1-5 is fixedly connected with the piston rod 1-4, hinged One end of the rotating rod 1-6 is hingedly connected to the hinge terminal 1-5, the other end of the hinged rotating ro...

specific Embodiment approach 3

[0038] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain the first embodiment, the one-way valve assembly 2 includes an inlet valve sleeve 2-1, a one-way ball 2-2, an outlet valve sleeve 2-3, and a connecting plate One 2-4, one-way push spring one 2-5, one-way ball two 2-6, through hole one 2-7, connecting plate two 2-8, one-way push spring two 2-9, through hole two 2- 10. The second through hole 2-10 is set on the air valve casing 2-1, the one-way ball 2-2 is connected with the second through hole 2-10, and the connecting plate two 2-8 is connected with the air valve casing 2 -1 is fixedly connected, the one-way push spring two 2-9 is arranged between the one-way ball one 2-2 and the connecting plate two 2-8, the connecting plate one 2-4 is fixedly connected with the outlet valve casing 2-3, and the Hole one 2-7 is arranged on the outlet valve casing 2-3, one-way ball two 2-6 is connected with through hole one 2-7, and one-way push spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com